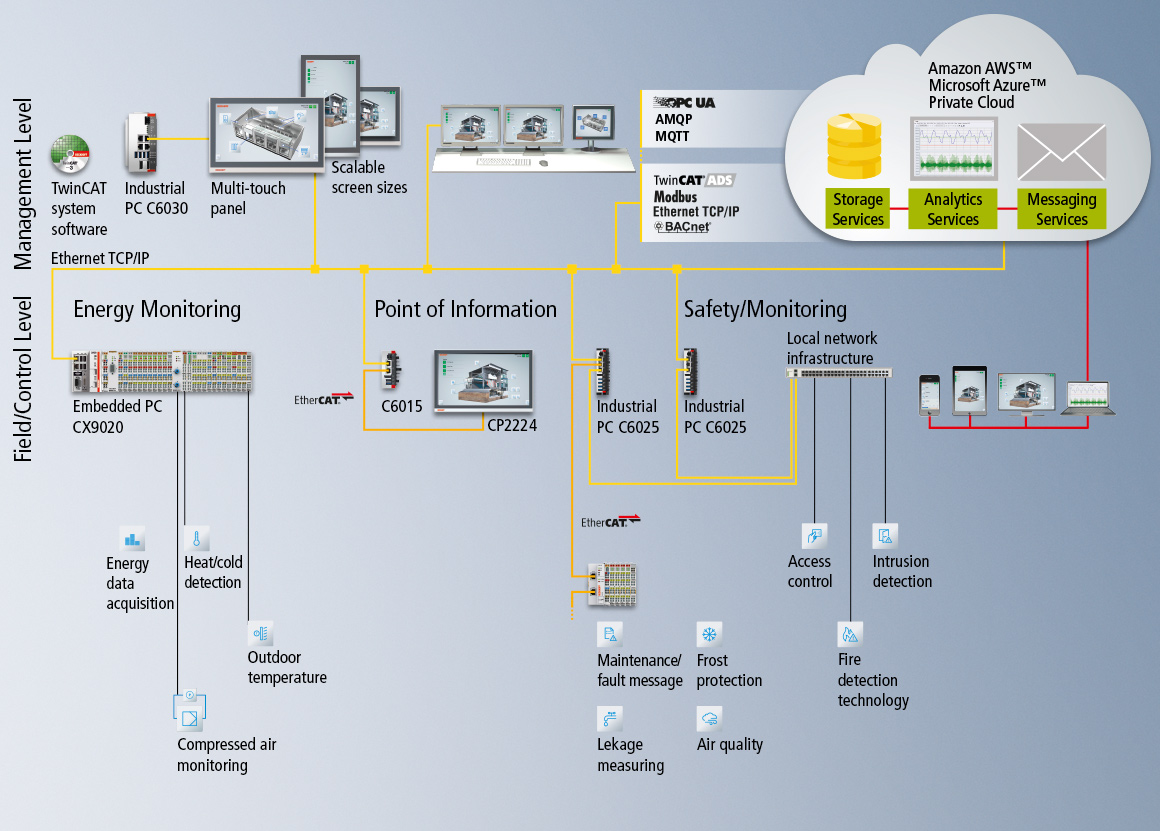

The ability to monitor the status of equipment and access control systems – anytime and anywhere in the world if desired – is becoming more important with each passing day. Operators and service engineers in a control center can check anytime whether devices installed in the field are operating properly. The support for standard interfaces as well as all vendor-specific protocols of relevance for a specific industry makes the Beckhoff control system an open platform that offers users maximum flexibility to realize their applications. A single platform can be used to monitor the status of various third-party systems, for example, an array of monitors or various different physical parameters.

The Beckhoff control system can be flexibly expanded thanks to its inherent modularity. If, for example, new functions like energy are to be extended, this can be solved by placing a decentral I/O terminal to the network and with a simple software update, for instance. Beckhoff also offers a wide variety of elegantly designed multi-touch Control Panels and Panel PCs for operator interface and monitoring. Display sizes ranging from 7 to 24 inches allow users to choose the ideal device for their application.

Further information about our technologies and products for operating and monitoring can be found here: