PC-based control for media technology

Beckhoff and

PIXERA: control

and projection in

perfect harmony

Headquarters Canada

Beckhoff Automation Ltd.

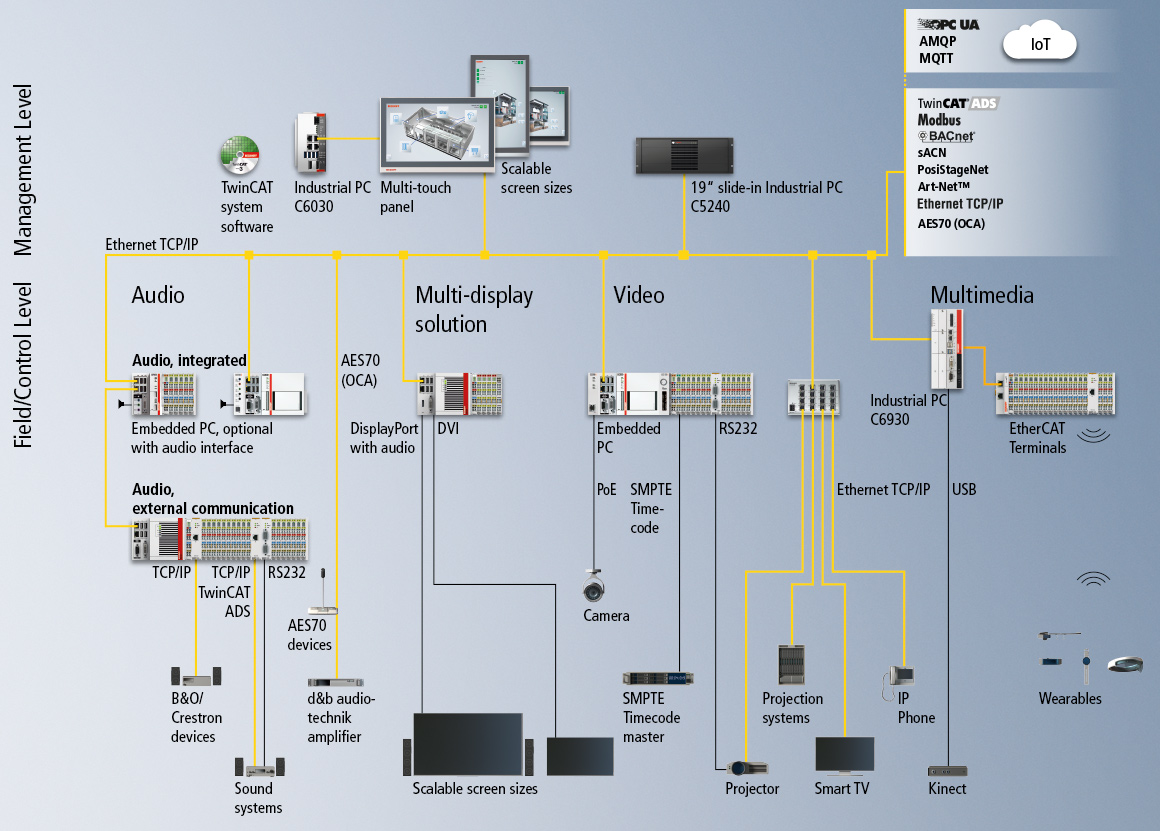

In addition to Ethernet TCP/IP, serial protocols and OPC UA, the Beckhoff control platform supports all relevant protocols in the area of media technology. This includes Open Control Architecture (AES 70 standard), PJLink, SMPTE-Timecode, Crestron, Bang & Olufsen, Art-Net™ and Streaming ACN (sACN), among others. Vendor-independent control of the widest range of media technology equipment enables the seamless operation of audio and video systems, display devices, multimedia servers and streaming services – in one network and on the same platform. The advantage for users is clear: they are not restricted in their choice of media technology equipment and are free from manufacturer-specific protocol considerations. The Beckhoff platform serves as a multi-language gateway, ensuring flexible communication among devices, as well as optimum usability.

Through the scalability and modularity of the software and hardware components from Beckhoff, users can tailor their control system precisely to the scope of the control tasks at hand. Users can achieve significant performance improvements and cost reductions, but also optimize available installation space. The CX5100 Embedded PC, for example, represents an extremely powerful and modular control solution based on multi-core processors from Intel®, helping to combine audio, PoE, Display Port and DVI on one universal platform.

Further information about our technologies and products for AV and media control can be found here: