Beckhoff Australia provides products and support to build Ampcontrol’s Ventasys ventilators

As the world entered March 2020 battling the Covid-19 pandemic, it became clear that global shortages of vital medical equipment could impact efforts to respond to the escalating crisis in the Australian state of New South Wales (NSW). Following a call to industry and university partners, NSW Health embarked on a Rapid Innovation Project to explore how new ideas could provide back-up ventilator solutions to support frontline workers. Two specialists, Ampcontrol and Beckhoff, immediately offered their expertise.

Ampcontrol, a leading engineering company founded in Newcastle, Australia, in 1968, responded to the NSW Government’s ‘call-to-arms’ in March 2020 to develop a life-saving back-up ventilator solution during the COVID-19 pandemic. Ampcontrol Managing Director & CEO Rod Henderson said, “We are so immensely proud to be able to do our part and lead this critical health project in the manufacture of emergency ventilator solutions. Knowing that our ventilator could help save lives in the fight against COVID-19 is incredible.” Beckhoff Australia supported this project closely from the beginning and successfully delivered an effective and reliable control solution. Nick Psahoulias, Managing Director of Beckhoff Australia, emphasizes: “It is through collaboration on a common goal that we can achieve great things, in a short time.”

First functional prototype developed in only 18 days

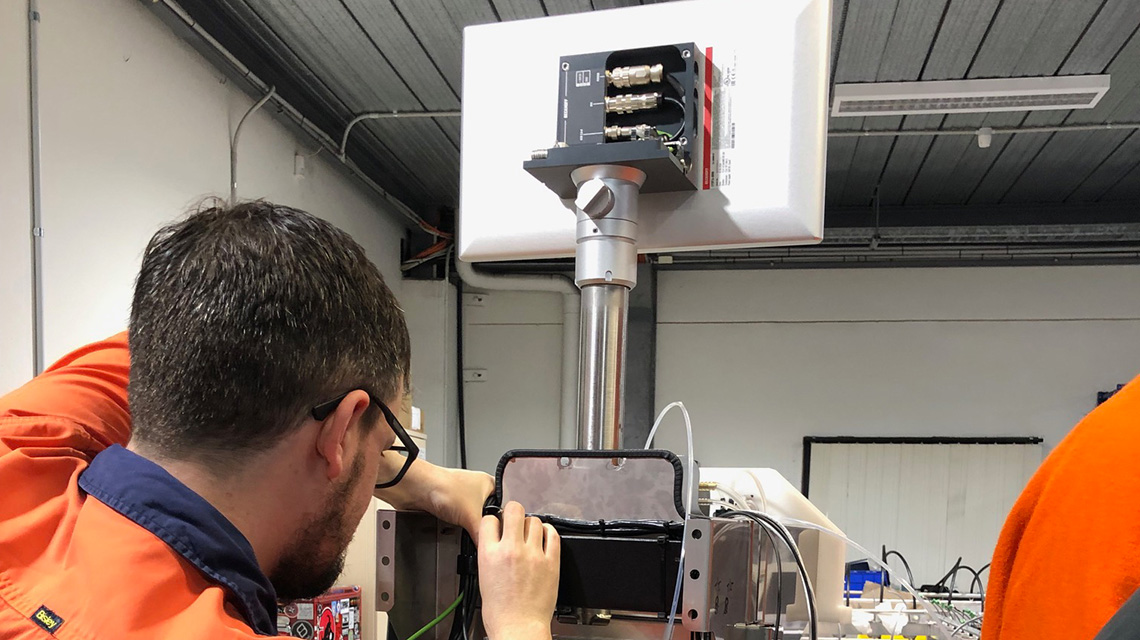

Five groups came forward to develop prototype ventilators after a callout to industry and university partners. Ampcontrol’s Ventasys Ventilator was one of two solutions selected for further development and testing to meet regulatory requirements in a pre-production stage. Ampcontrol engineers designed and delivered the first functional emergency ventilator prototype to the John Hunter Hospital Simulation Unit for testing by specialist clinicians in just 18 days.

Health Infrastructure Chief Executive Rebecca Wark said partnerships and collaboration have been

essential to the success of this project: “Our partners have helped us to innovate and solve intense challenges at a rapid pace. Bringing the industry and university partners together helps us to develop creative solutions to the challenges we face, not only today with COVID-19, but into the future.”

“Ampcontrol started to develop four different ventilator concepts, with 15 to 20 multi-disciplined engineers working around the clock to deliver a working ventilator in only four weeks. With the full support of the Beckhoff engineering and manufacturing departments, this time frame was able to be met,” Nick Psahoulias said.

The Beckhoff control solution

The Ventasys ventilator is equipped with a Beckhoff CP3916 15.6-inch multi-touch Control Panel and C6015 ultra-compact Industrial PC (with a quad-core Intel Atom® processor) as the PLC and HMI solution. TwinCAT 3 HMI software ensures a modernized and user-friendly graphical operator interface. It fulfills perfectly the comprehensive technical requirements of this application, e.g. historic data recording. Special I/O components such as EtherCAT Terminals for pressure measurement and EtherCAT Box modules saved development time.