TwinCAT 3 Engineering

Configuration, programming and debugging of applications with TwinCAT 3 Engineering.

中国区总部

毕孚自动化设备贸易(上海)有限公司

+86 21 6631 2666

info@beckhoff.com.cn

www.beckhoff.com.cn/zh-cn/

Configuration, programming and debugging of applications with TwinCAT 3 Engineering.

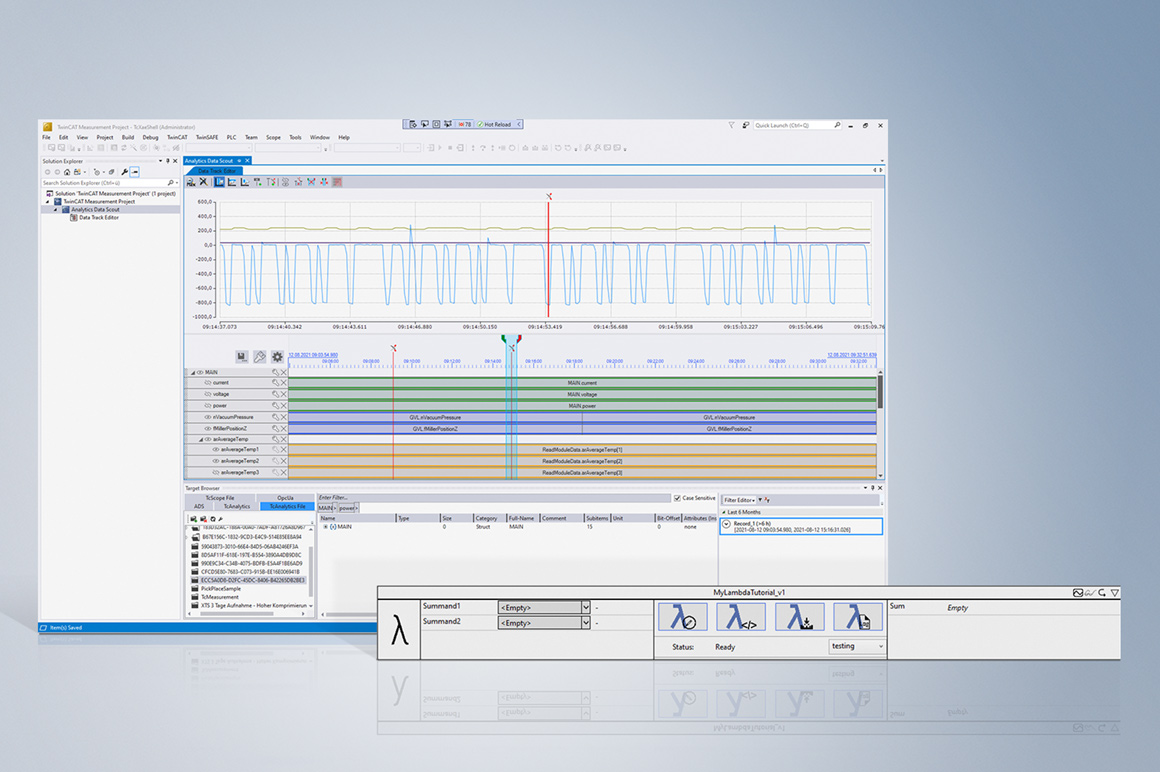

The TwinCAT Analytics workflow, from data acquisition to continuous data evaluation, is supplemented by an important component in the area of data engineering with TE3500 and TE3520. The new TwinCAT 3 Analytics Data Scout is responsible for viewing data even before the actual analysis. It allows analytics recordings to be loaded in different depths of detail and with particularly high performance, so that the users obtain an overview of their long-term recordings as fast as possible. Significant points that the user wants to analyze in greater depth can be identified and located in the data stream just as easily as possible dead times that are not to be included in the analysis. The so-called data tracks can be handled in a similar way as in an image processing program. The Data Scout is able to cut out recording areas or to reassemble recording parts from different points in time. Data types can be converted for the purpose of memory optimization. The rather artificially created image can be saved and used for the actual analysis.

The fact that the TwinCAT Analytics workflow is completely open is demonstrated by the new TwinCAT 3 Analytics Lambda Function. The Lambda Function allows you to write your own fully wizard-based analysis algorithms in C++. The algorithms can be deployed in a test mode or as a release. After release, the company's own algorithms are available in the toolbox of the engineering environment, just like the now more than 60 standard algorithms of TwinCAT Analytics, and can be used as often as required in different projects. With the Analytics HMI Mapping Wizard, it is even possible to map your own C++ Lambda Function with one of the existing Analytics HMI Controls or with a fully self-developed HMI Control. So, in fact, the entire workflow, including automatic PLC code and HMI dashboard generation, is covered for custom algorithms.

Both functions are available with the products TE3500 Analytics Workbench and TE3520 Analytics Service Tool.

TwinCAT 3 Analytics Workbench 是一款 TwinCAT 3 开发环境产品,用于从各种空间分布的设备控制器中创建持续数据分析。工作台的配置集成在 Microsoft Visual Studio® 中,用作图形用户界面。用于配置分析的工具箱中提供了许多算法:

TwinCAT 3 Analytics Service Tool 是设备调试和维修工程师的理想工具。通过物联网连接可以检索实时和历史数据以进行分析。分析在 Microsoft Visual Studio® 中进行配置,用户可以在这里轻松访问算法工具箱,以实施相关的生命周期、循环时间、包络线或组件计数器分析。算法的输出可以用作其它算法的输入,或者直接在图形编辑器中作为结果输出。使用 TwinCAT Scope 绘图工具进行的并行记录可以轻松显示信号通路。用户可以直接将分析结果从分析配置工具中拖出并放入绘图工具中,以标记数据流中哪些位置是重要的。产品组件之间的交互特别在诊断机器行为方面有优势,并能够突出优化潜力。由于使用了物联网技术,用户在哪已经不重要,这意味着维修技术人员可以从几乎任何位置执行系统和设备诊断。