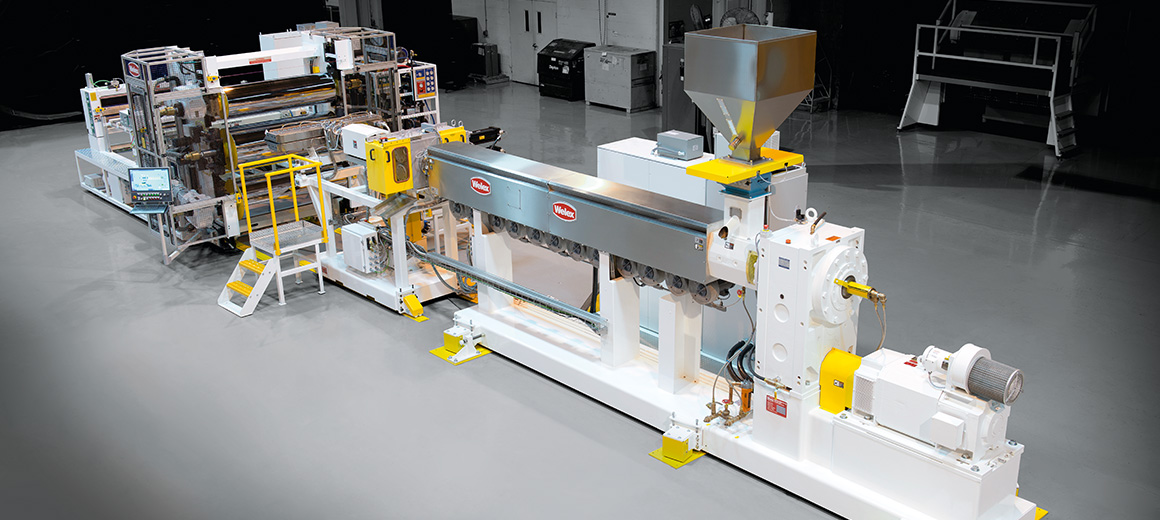

PC-based control becomes the standard for sheet extrusion applications

Graham Engineering, Pennsylvania, USA

Extrusion heads and extruders,for retrofitting blow molding machines

W. Müller GmbH, Germany

Headquarters United States

Beckhoff Automation LLC

+1 952 890-0000

beckhoff.usa@beckhoff.com

www.beckhoff.com/en-us/

Graham Engineering, Pennsylvania, USA

W. Müller GmbH, Germany

Depending on the material and end product being processed, the requirements for extrusion processes vary a great deal, from precise temperature control with a short settling time to process control for melt throughput, wall thickness or film thickness. Detailed energy recording is absolutely necessary for sustainable production.

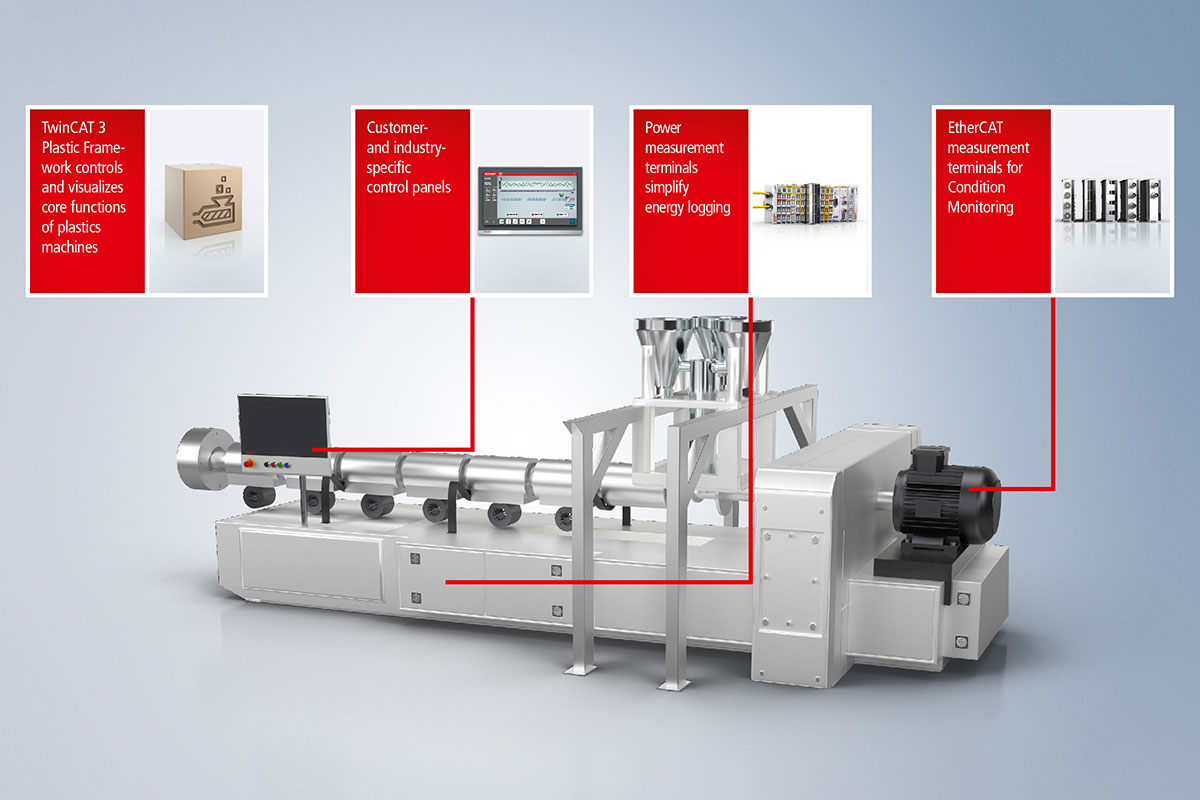

With its open, precisely scalable and modular control technology, Beckhoff meets the requirements for extrusion technology – be it recycling, tube and profile extrusion or blow film extruder - for performance-oriented and cost-effective solutions. An extensive portfolio of industrial PCs, EtherCAT as a fast communication system, the decentralized I/O modules, drive technology components and the TwinCAT automation software make up the universal hardware and software platform for the automation of extrusion plants. As if from a construction kit, the user can assemble a suitable control solution for the system or plant type. Depending on the system execution and size, Beckhoff offers control panels in different form factors and if necessary in a customer-specific execution.

For the efficient automation of extruders, machine manufacturers have an extensive range of software and hardware components at their disposal:

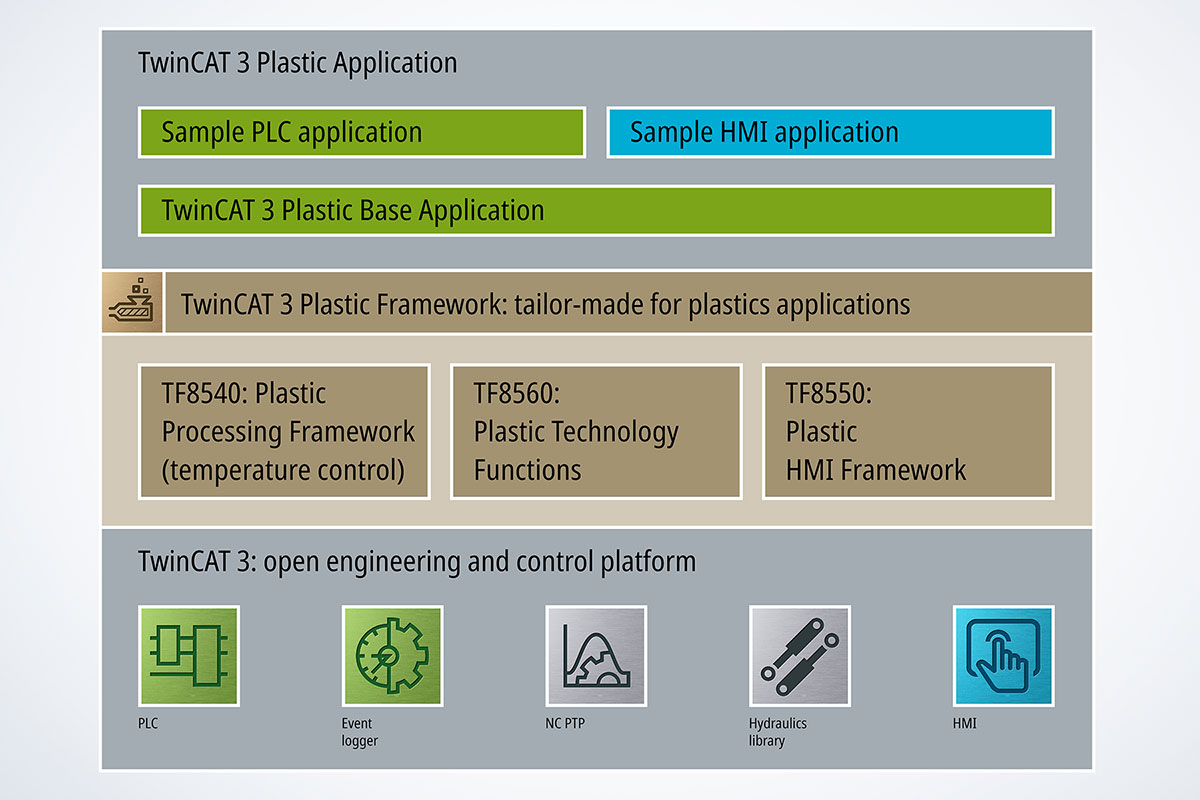

With the TwinCAT 3 Plastic Framework, we offer a modular software solution for the control of plastics machines that minimizes development effort and maintains the open nature of Beckhoff architecture. The TwinCAT 3 Plastic Framework brings together our many years of expertise in plastics, seamlessly integrating important industry-specific functions into the established TwinCAT environment. As a result, plastics machines can be programmed, visualized, and controlled on a single platform.

The TwinCAT 3 Plastic Framework contains three software libraries: TF8540 enables comprehensive software-based temperature control in plastics processing. TF8560 is a technology package that provides all the components for controlling motion functions in plastics machines. TF8550 is an HMI package specially developed for the plastics industry that enables the visualization of typical processes with minimal engineering effort and integrates seamlessly into the other technology packages.

Integrated, application-specific templates and sample code for various plastics applications facilitate project planning and programming, and are made available free of charge via the TwinCAT 3 Plastic Application. Of course, existing templates can also be used and your own process expertise can be integrated.

TF8540: Plastic Processing Framework

TF8560: Plastic Technology Functions

TF8550: Plastic HMI Framework

An innovative and sustainable tool for creating user interfaces for extrusion machines is available to the user in TwinCAT HMI. In addition to the display on the machine panel, the HTML5-based architecture also enables the presentation of machine data in the same design on mobile devices such as smartphones or tablets. The TwinCAT Plastic Application Components for extrusion include process-specific technology modules and the corresponding HMI objects, for example for temperature control. This allows machine manufacturers to put together their own solution or, for example, to use a turnkey solution for retrofit projects.

The analysis of big data and secure communication between the machine controller and the cloud take place via TwinCAT IoT, either integrated into the standard controller or via an IoT coupler.