The EL7201-9014 servomotor EtherCAT Terminal with integrated absolute value interface offers high servo performance in a very compact design. The fast control technology, based on field-oriented current and PI speed control, supports fast and highly dynamic positioning tasks. The monitoring of numerous parameters, such as overvoltage and undervoltage, overcurrent, terminal temperature or motor load via the calculation of a I²T model, offers maximum operational reliability. EtherCAT, as a high-performance system communication, and CAN-over-EtherCAT (CoE), as the application layer, enable ideal interfacing with PC-based control technology. The latest power semiconductors guarantee minimum power loss and enable feedback into the DC link when braking. 16 LEDs indicate status, warning and error messages as well as possibly active limitations.

With the One Cable Technology (OCT) the encoder cable is omitted by transmitting the signals of the encoder digitally via the existing motor cable. The option to read the electronic identification plates of suitable motors from the AM81xx series enables a plug-and-play solution for maximum convenience during commissioning.

The STO function according to EN 61800-5-2, can be implemented using the reaction-free HWE input corresponding to a safety level Cat. 3, PL d according to DIN EN ISO 13849-1:2015 (see document "EP7211-0034 | TwinSAFE application example").

Product status:

regular delivery

Product information

| Technical data | EL7201-9014 |

|---|---|

| Protocol | EtherCAT |

| Technology | compact drive technology |

| Connection method | direct motor connection with OCT |

| Number of inputs | 2 x end position, 1 x feedback, 1 x STO |

| Load type | permanent magnet-excited three-phase synchronous motor |

| Number of channels | 1 |

| Number of outputs | 1 x servomotor, 1 x motor brake |

| Supply voltage electronics | 24 V DC (via power contacts) |

| Supply voltage power | 8…48 V DC (external) |

| Output current (rms) | 2.8 A |

| Peak current (rms) | max. 5.7 A for 1 s |

| Performance increase | yes, through ZB8610 fan cartridge |

| Output current with ZB8610 (rms) | max. 4.5 A |

| Peak current with ZB8610 (rms) | max. 9.0 A for 1 s |

| Rotating field frequency | 0…599 Hz |

| PWM clock frequency | 16 kHz |

| Current controller frequency | 32 kHz |

| Rated speed controller frequency | 16 kHz |

| Output voltage motor brake | 24 V DC |

| Output current motor brake | max. 0.5 A |

| Current consumption power contacts | typ. 100 mA + holding current motor brake |

| Current consumption E-bus | 120 mA |

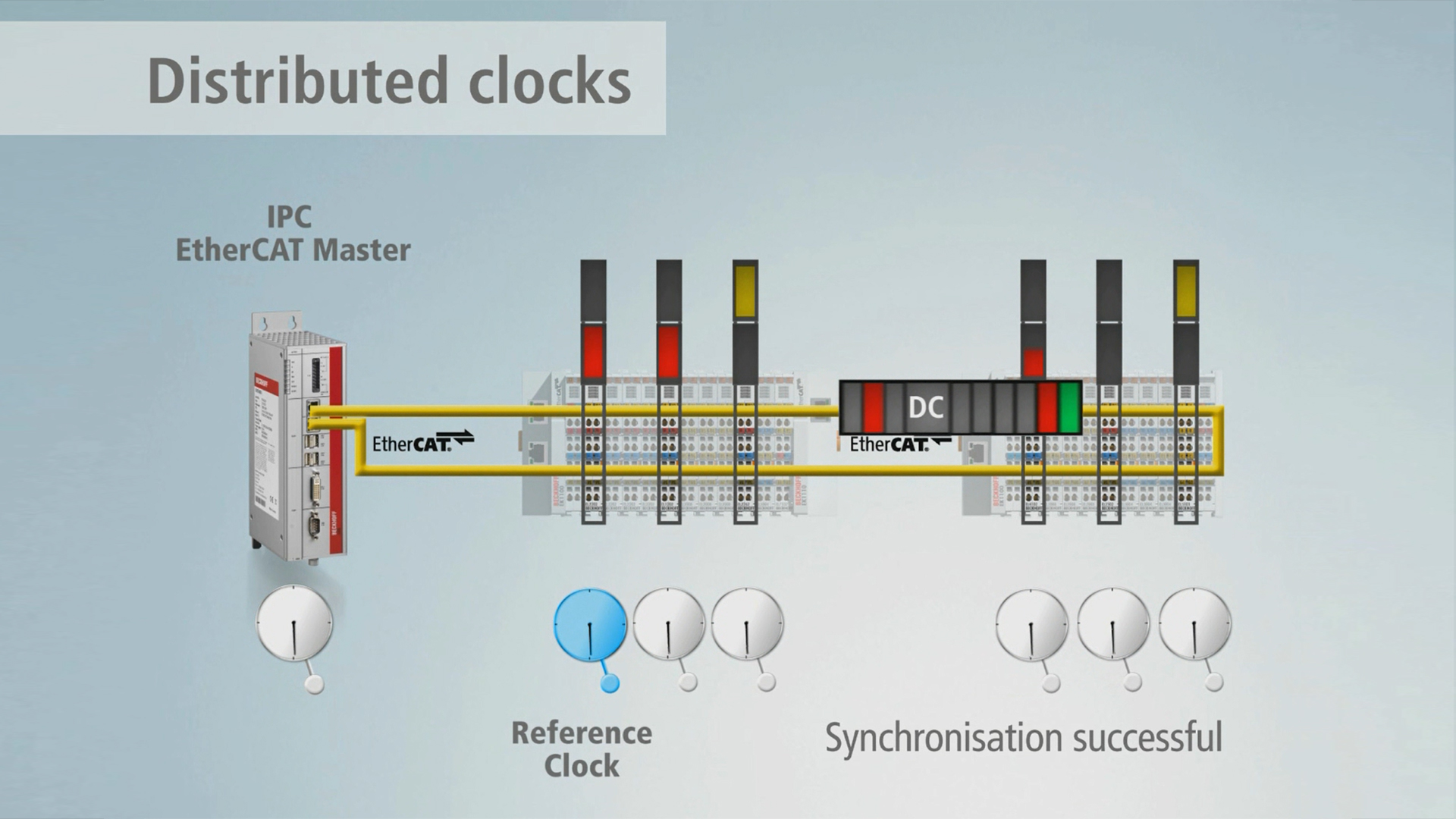

| Distributed clocks | yes |

| Realization STO | hard-wired via safe output |

| Special features | compact (only 12 mm wide), absolute feedback, One Cable Technology (OCT), integrated track control |

| Safe stop functions | Safe Torque Off (STO) |

| Electrical isolation | 500 V (E-bus/field potential) |

| Weight | approx. 60 g |

| Operating/storage temperature | 0…+55°C/-25…+85°C |

| Relative humidity | 95%, no condensation |

| EMC immunity/emission | conforms to EN 61000-6-2/EN 61000-6-4 |

| Vibration/shock resistance | conforms to EN 60068-2-6/EN 60068-2-27 |

| Protect. rating/installation pos. | IP20/see documentation |

| Approvals/markings | CE, UL, TÜV SÜD |

| Housing data | EL-12-16pin |

|---|---|

| Design form | HD (High Density) housing with signal LEDs |

| Material | polycarbonate |

| Dimensions (W x H x D) | 12 mm x 100 mm x 68 mm |

| Installation | on 35 mm DIN rail, conforming to EN 60715 with lock |

| Side by side mounting by means of | double slot and key connection |

| Marking | labeling of the BZxxx series |

| Wiring | solid conductors (s): direct plug-in technique; fine-stranded conductors (st) and ferrule (f): spring actuation by screwdriver |

| Connection cross-section | s*: 0.08…1.5 mm², st*: 0.25…1.5 mm², f*: 0.14…0.75 mm² |

| Connection cross-section AWG | s*: AWG28…16, st*: AWG22…16, f*: AWG26…19 |

| Stripping length | 8…9 mm |

| Current load power contacts | Imax: 10 A |

*s: solid wire; st: stranded wire; f: with ferrule

Loading content ...

Loading content ...

Loading content ...

Loading content ...

Loading content ...

Loading content ...

© Beckhoff Automation 2024 - Terms of Use