Products

Accessories overview

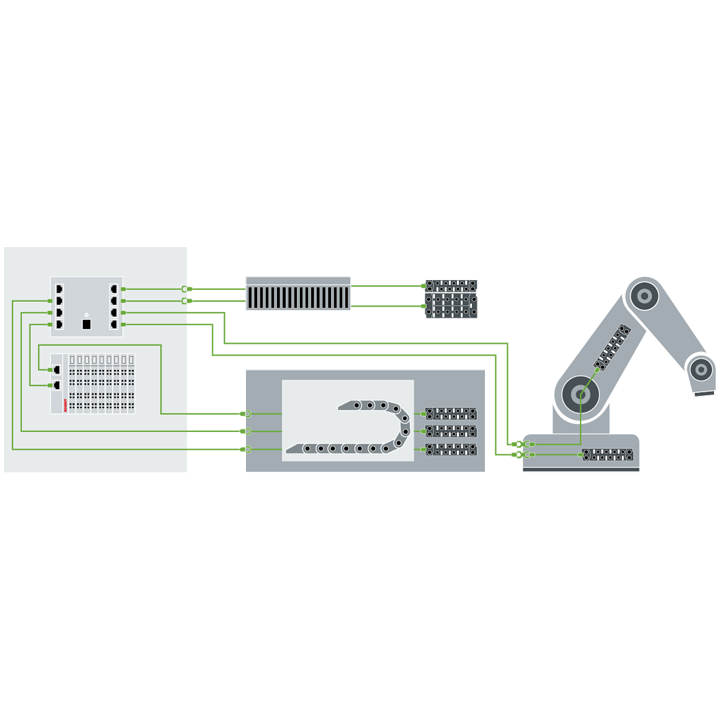

The overviews shown provide a selection of cabling options with control cabinet entry systems for different applications.

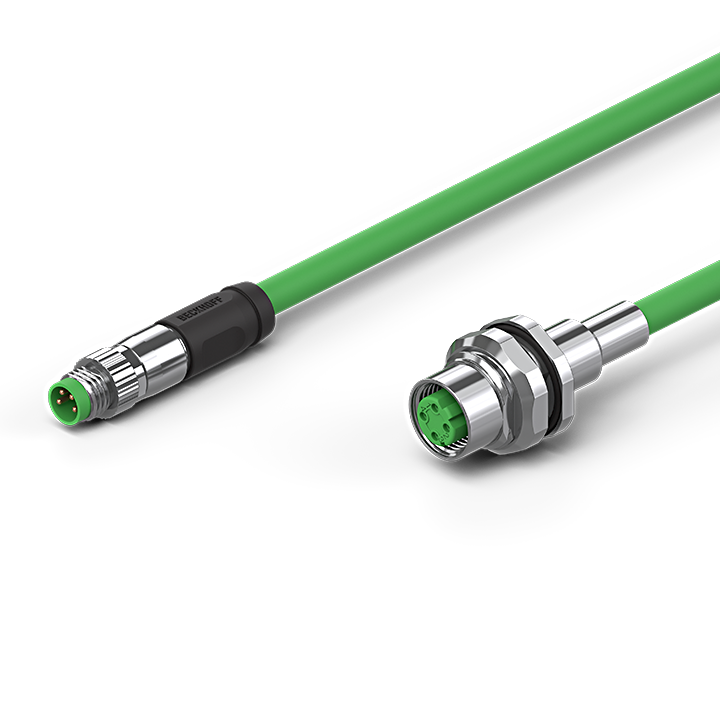

Pre-assembled cables

The portfolio's wide selection ranges from motor cables to communication cables to sensor, power and hybrid cables.

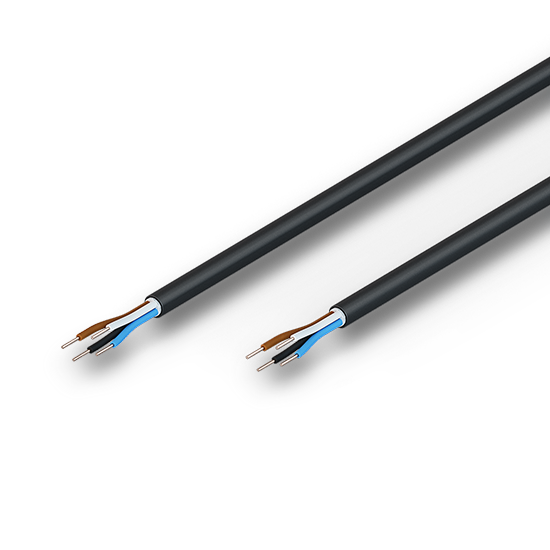

Cable by the meter

Cables sold by the meter for direct assembly in the field are available ex stock as lenghts sold by the meter, coil, reel or drum.

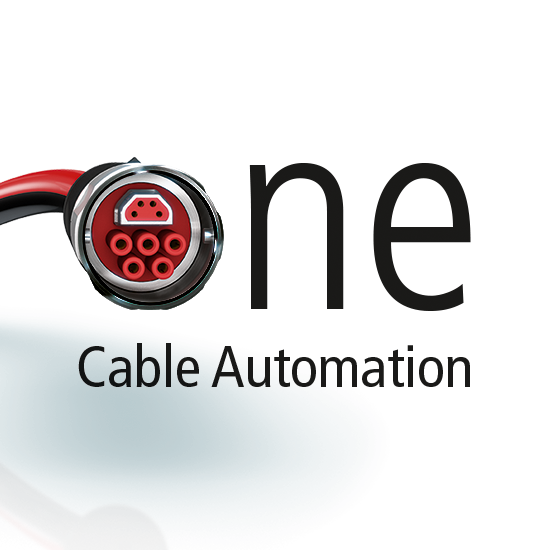

OCA | One Cable Automation

One Cable Automation facilitates efficient and optimal cabling for devices, machines, and systems.

Adapters, PCB connectors and connectors for field assembly

Connectors for field assembly are available in application-dependent versions.

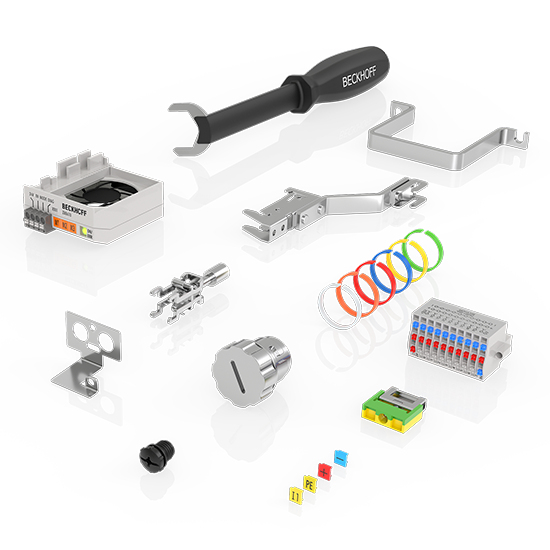

I/O-specific accessories

Beckhoff offers further accessories for building compact I/O stations with reliable cabling.

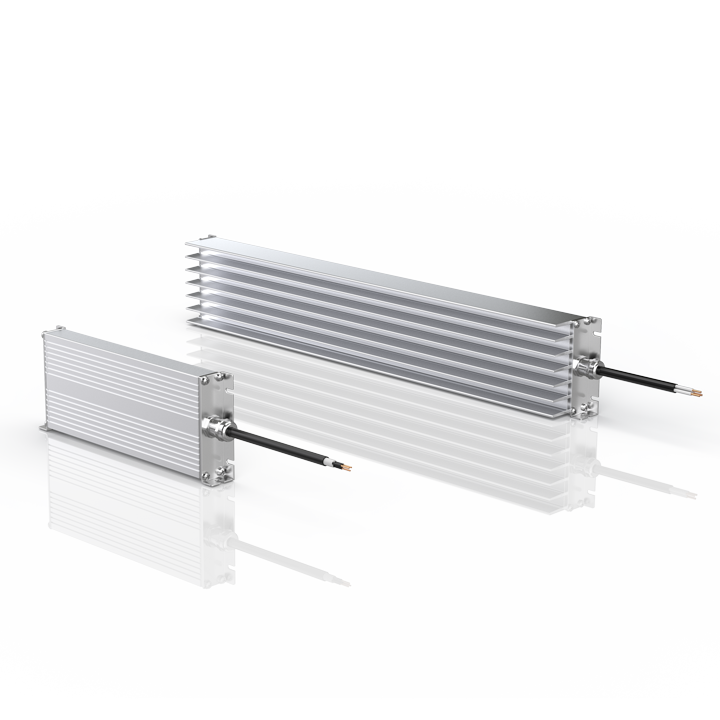

Motion-specific accessories

Complete, practice-proven range of accessories with which all motion solutions can be optimally integrated.

Vision-specific accessories

Vision-specific accessories include products for mounting the hardware and accessories for extended use of the optical components.

The safe connection for every application

As a specialist in PC-based control technology, Beckhoff has been developing, designing, and manufacturing high-quality I/O and motion components for decades. Existing know-how and technologies are subject to consistent optimization. This is reflected, among other things, in a complete and tried-and-tested portfolio of accessories, with which all I/O, Industrial PC, and motion solutions are optimally integrated into the control architecture. Thanks to a full range of I/O and motion accessories including motor, communication, sensor, power, and hybrid cables, customers benefit directly from high-end technology "Made in Germany".

The portfolio includes not only connection elements such as cables and connectors, but also marking and labeling systems, extension components such as the ZB8610 fan cartridge, and tools to ensure consistent contacting of connections.

The virtually seamless range covers not only all the familiar Beckhoff accessories, Beckhoff also offers an extended choice of connection products for the entire automation industry.

Advantages

- complete state-of-the-art portfolio

- wide variety: from simple label to complex hybrid cable

- in-house expertise

- high-quality, coordinated product portfolio

- tested and certified quality of all components

- standardized components for the entire automation industry

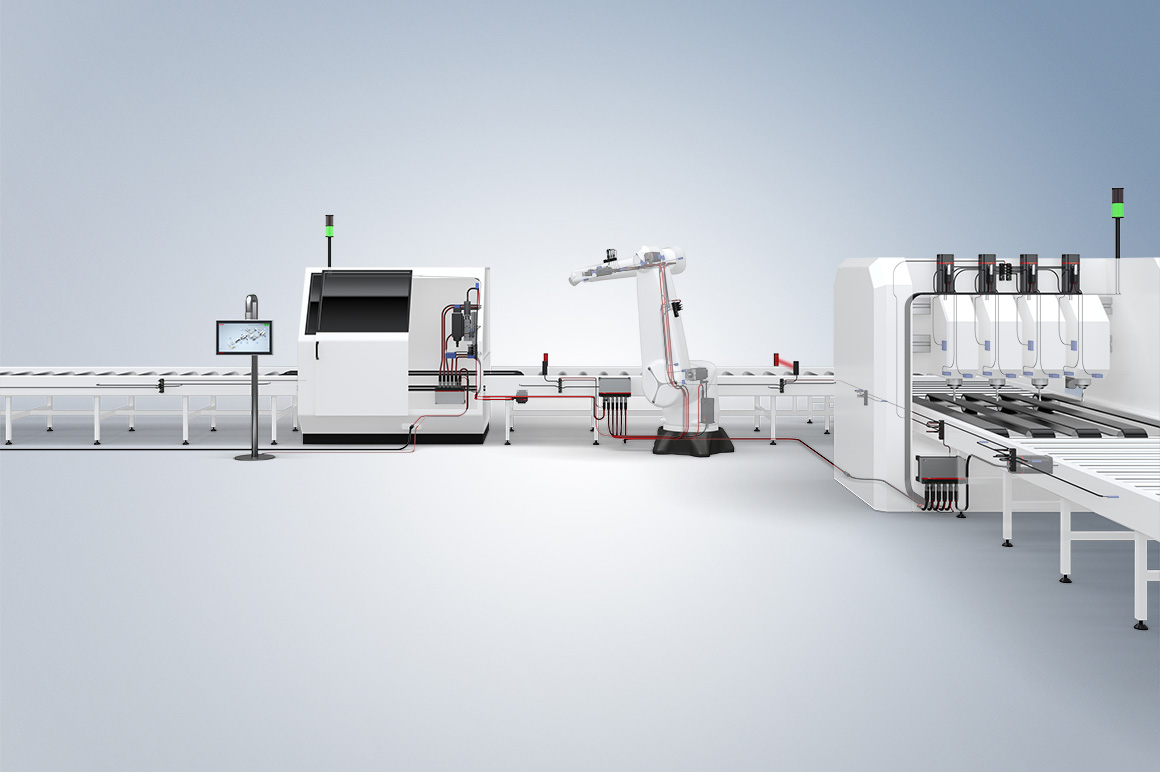

The ideal cabling solution

In machine systems with conventional cabling, lines from the sensors and actuators are routed centrally to a main control cabinet. Large cable cross-sections are usually used to compensate for voltage losses due to long distances between the central control cabinet and the sensors and actuators. This results in large bundles of cables both in and in front of the control cabinet, which means a lot of work during commissioning and an increased likelihood of errors.

Cabling work is demanding in systems with a central control cabinet, and this can be significantly mitigated by using OCA technology and hybrid cables. The control cabinet is completely eliminated by relocating decentralized connection points directly into the individual devices of the system. This future-proof technology is ideal for ensuring space-saving, well-organized, and maintenance-friendly distribution of data and power cables, as well as for connecting sensors and actuators.

Cabling is an important part of machines. The reliable function of the cables and connectors should be guaranteed, especially in systems with large cable bundles, in order to avoid failures and downtimes.

Modules for direct I/O field installation provide the basis for simple plug-and-play solutions: Efficient cabling minimizes potential for error. The starting point is One Cable Technology (OCT).

One Cable Automation (OCA) for the entire field level: One-cable solutions can have a positive impact at almost every level and device: Communication and supply through a single line saves space, time, and money. The machine footprint is reduced.