Power generators and suppliers are facing major challenges right now. Climate targets need to be met and consumers need to be supplied with reliable and affordable energy, but there is still a huge gap between conventional and renewable power generation. This is why, in the medium term, it is essential to increase sustainability across all areas through efficient automation. Rely on control technology from Beckhoff for resource-saving power generation in conventional power plants and the reliable provision of renewable energies.

Here’s how you can take action with Beckhoff:

- turning to power generation with sun, wind, water, biomass, and geothermal energy

- producing green hydrogen with renewable energies

- implementing solutions for storing wind or solar energy

- operating power plants efficiently with fossil fuels

- switching to combined heat, power, and cooling in large and small power plants

Our product highlights for intelligent power generation

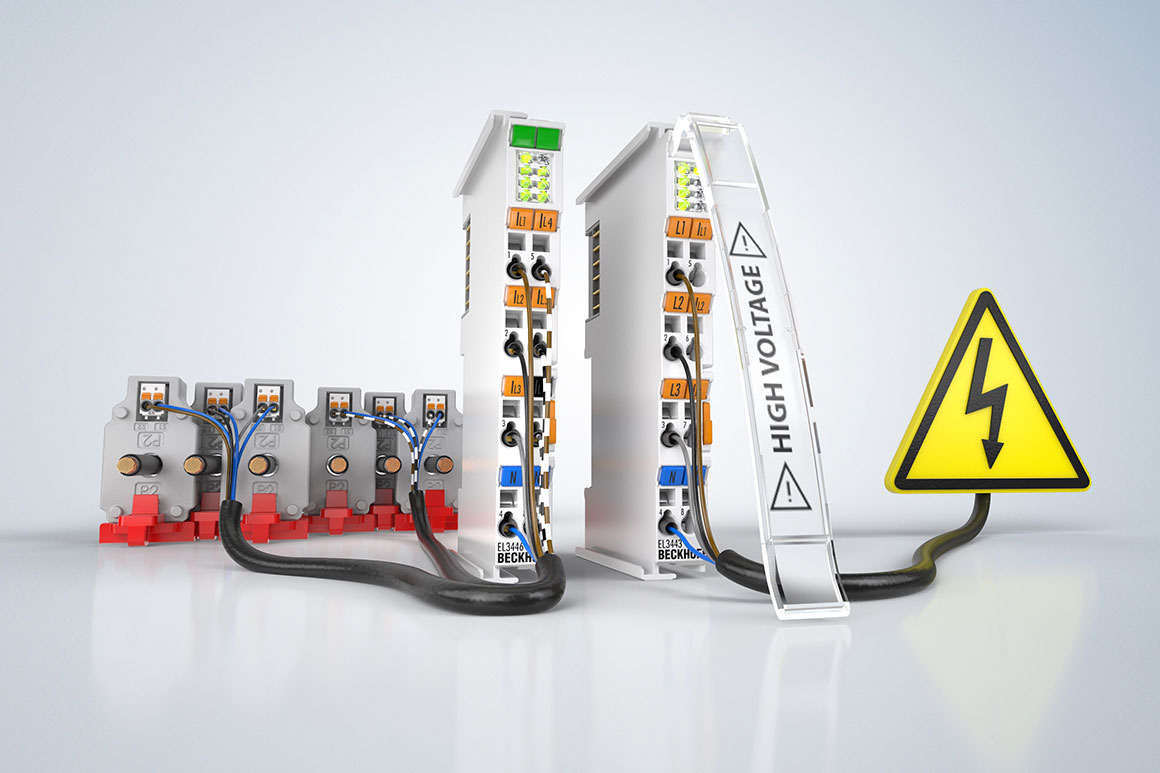

Power and energy measurement

Power generators are faced with the challenge of complying with setpoint specifications for grid feed-in and adapting the regulation of current, voltage, and frequency accordingly in power plants, wind farms, and solar parks. System-integrated measurement technology forms the backbone for ultra-fast networking with EtherCAT: The EL3783 power measurement terminal records instantaneous values of current and voltage at up to 20,000 samples/s. With distributed clocks, the measured values for all decentralized systems and the feed-in point can be synchronized to a time window of less than 1 μs.

Energy monitoring with TwinCAT Analytics

The TwinCAT Analytics product family provides a complete workflow for energy monitoring in distribution grids – from data acquisition, communication, and data historization to analysis and visualization. What’s more, the openness of the PC-based control technology facilitates integration with third-party solutions for data evaluation and system control in the grid control systems of power generation companies, utilities, and grid operators.

Redundancy with EtherCAT

System availability plays a decisive role when it comes to power generation. EtherCAT offers various redundancy options with TwinCAT to safeguard against control component failures. The first stage involves establishing a redundant cable connection from the last EtherCAT slave to the master. In the second stage, a redundant network connection ensures communication between the control hardware and higher-level systems. For redundant control operation with two industrial PCs, TwinCAT Controller Redundancy is available.

Condition monitoring

Condition monitoring with Beckhoff minimizes the risk of failures, reduces maintenance costs, and enhances the energy efficiency of power generation plants. The vibrations of bearings or electrical machines are picked up by measurement terminals such as the EL3632 for connecting IEPE sensors and transmitted to the controller via EtherCAT. The measuring signals are then analyzed on the PC via the TwinCAT library or other user software.

Connecting power generators for the grid of the future

The growing adoption of renewable energies is elevating the requirements for energy management at the interface with the broader power supply network. To ensure sufficient grid stability, power generators have to be able to compensate for fluctuations in the available energy before feeding it into the grid. This requires efficient communication between plants. Connectivity also has to be established in the other direction, so that decentralized systems can feed back into the grid from the consumer side.

With its outstanding connectivity, PC-based automation simplifies the process of networking power generation systems with control centers, grid operators, and municipal power suppliers. Telecontrol protocols such as IEC 60870-5-10x and IEC 61850 can be installed as a library of the TwinCAT automation software and facilitate remote monitoring and operation optimization. By connecting to the cloud and providing data through OPC UA, energy monitoring is made more transparent with secure data access for different user groups.

Energy projects implemented with Beckhoff

Control technology and data monitoring for containerized biogas power plants

Just flip the switch – that could quite easily be the motto of Reverion’s biogas power plants on the way to a climate-friendly energy supply. As if the compact design housed in a single transportable container didn’t make using this energy technology easy enough already, its exceptionally high efficiency of 80%, reversible usage option, and seamless data monitoring with PC-based control from Beckhoff all serve as prerequisites for achieving a high level of automation.

Sven Bettendorf is an application engineer at Reverion, who explains that the company’s goal is to help solve two of the biggest problems facing humanity by creating a truly sustainable energy system and removing gigatons of CO2 from the atmosphere. The new generation of biogas power plants makes it possible to maximize the potential of biogas and also benefit from surplus solar and wind energy that would otherwise remain unused.

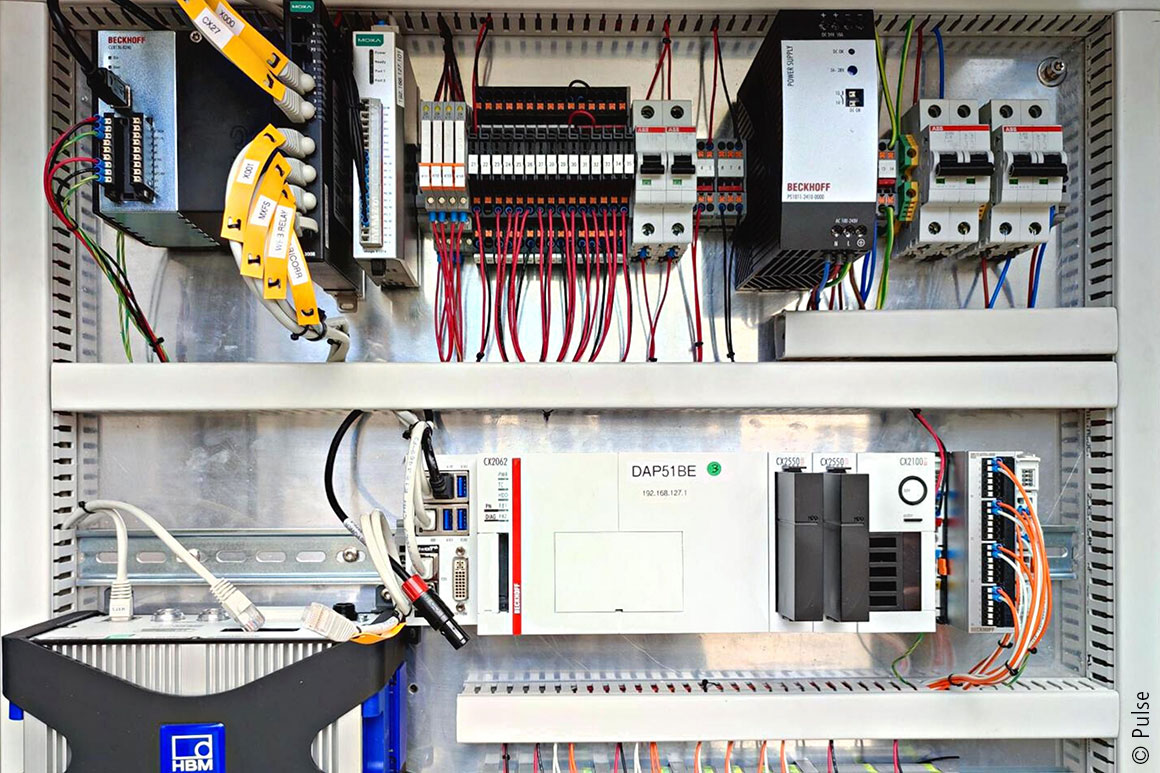

EtherCAT measurement terminals used to monitor wind farms

According to Pulse, the United Kingdom is the world leader in offshore wind energy and has more installed capacity than any other country. Nevertheless, the environmental conditions associated with wind farms such as these pose real challenges that require continuous monitoring of the entire system. Monitoring the wind turbine, rotor blades, and foundation in this way facilitates informed decisions regarding planned maintenance and structural inspections, which in turn mitigates the risk of unplanned shutdowns or expensive repairs in then event of a failure.

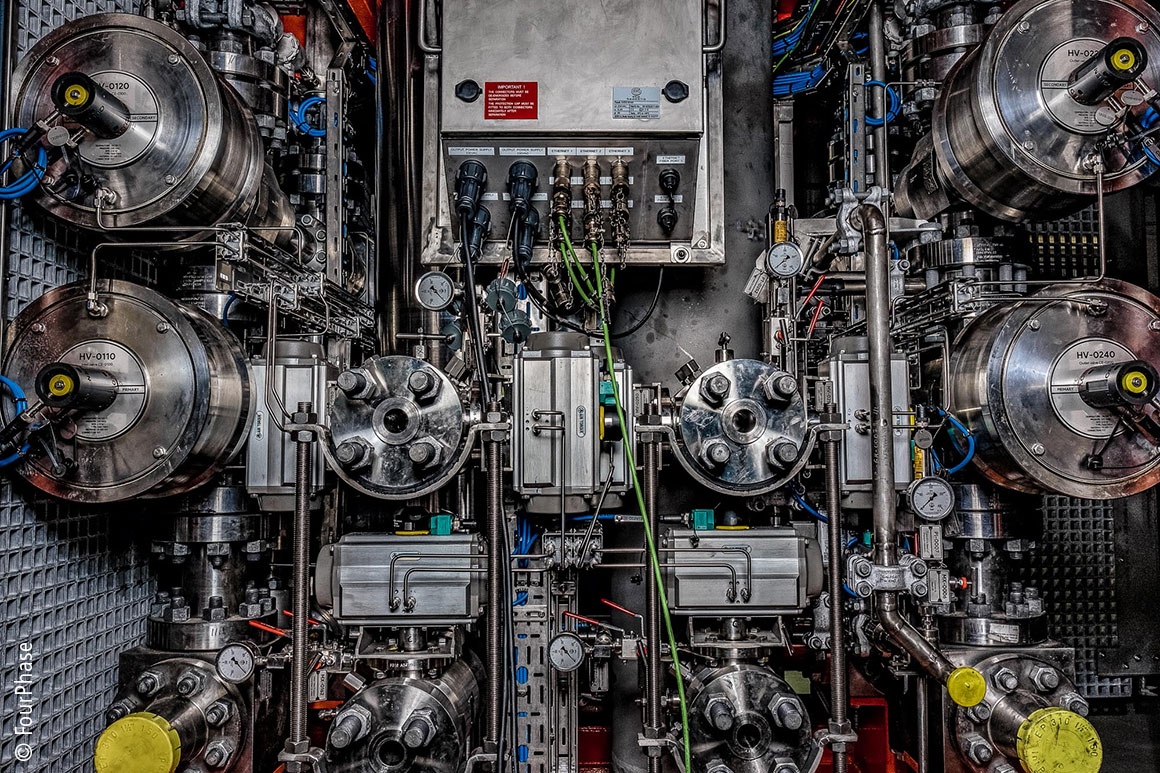

PC-based control optimizes oil and gas production

Since it was founded in Norway in 2012, FourPhase has been committed to optimizing and enhancing the efficiency of established oil and gas extraction processes through the use of modern technologies. Through its work, FourPhase paves the way for its customers to increase their production and remain consistently profitable. When it comes to implementing its innovative concepts, FourPhase puts its trust in Beckhoff components.

Working with an experienced team, the company aims to bring sustainable change to the traditional oil and gas industry. FourPhase ensures that solids are continuously separated from oil and gas production. This protects other system components, such as separators, valves, or pumps, enables solid-free flow, and creates the ideal conditions for producers to perform oil and gas extraction processes without costly and time-consuming interventions caused by wellbore blockages from solids. Ultimately, the FourPhase solution eliminates production downtime.

Nel Hydrogen relies on Beckhoff for environmentally friendly hydrogen refueling stations

Hydrogen is widely regarded as the energy carrier of the future, not least since it is a component of water and present in virtually all organic compounds. In other words, bound hydrogen is found in all living organisms. As an energy source, it does not produce carbon dioxide if it is generated using renewable energy sources such as wind or solar energy. The Danish company Nel Hydrogen has been a pioneer in the field of hydrogen technology for many years. With its hydrogen production concepts, Nel strives to make a decisive contribution to environmentally friendly mobility. Nel Hydrogen develops filling stations and dispensers for cars, buses, and trucks. Fast real-time control and monitoring of each individual filling station component plays a major role in increasing reliability while reducing maintenance. These sophisticated software solutions are based on Beckhoff technologies.

Measure, connect, optimize – the benefits of Beckhoff technology are widespread:

Smart grids

Ensure intelligent energy distribution with transparent monitoring of availability and demand.

Sustainable buildings

Unlock potential savings through end-to-end building automation from the office to the production hall.

Efficient machinery

Optimize machines and plants with energy management and resource-saving automation.