MX-System: Pluggable system solution for control cabinet-free automation

A comparison of control cabinet technology over the past few decades reveals that the basic structure remains essentially unchanged, and the complexity of the required components and wiring has been consistently high. This is what prompted Beckhoff to develop a significantly more flexible and efficient control cabinet alternative in the form of the MX-System modular and pluggable automation toolkit. In the following interview, Marvin Düsterhus and Dr. Friedrich Klasing from Product Management MX-System talk through all the details, including the recent addition of a 3-row baseplate.

The MX-System was first introduced in 2021 and certainly has the potential to not only reduce the size of the traditional machine control cabinet, but even replace it completely. How have customer reactions and acceptance changed since then?

Marvin Düsterhus: A lot has actually happened since it first launched. To date, we have assessed over 70 real-world applications and successfully transformed them into corresponding MX-Systems. The inquiries we receive come from a wide variety of fields, ranging from test benches and packaging machines through to brewery automation systems. Moreover, the control cabinet solutions employed in these applications are also equally diverse, which demonstrates that a control cabinet-free machine using our MX-System can be of interest for any application. With the MX-System, it is not only possible to directly replace the control cabinet on-site, but also to arrange the entire control technology in a modular and decentralized way by breaking it down into smaller units. This realization has now also been embraced by our customers, and there is virtually no question today that the future of automation technology will be control cabinet-free. Completely control cabinet-free automation, as showcased by the MX-System, offers solutions to the challenges our customers are facing both now and in the future. These notably include complete modularization of the entire machine, standardization in components and processes, addressing the growing shortage of skilled personnel, and ensuring straightforward machine maintenance.

Dr. Friedrich Klasing: The MX-System is no longer considered just another way to implement automation solutions, but as an opportunity to stand out from the competition. The modularization of entire machines or their components has been a fundamental principle of machine building since the beginning of the industrial revolution, given the evident advantages it offers for repair and maintenance. Similar approaches have existed in software since the early days of computer programming and in hardware for electronic components; however, the control cabinet, acting as the link between mechanics and electronics, has successfully resisted this trend until now. The MX-System addresses this by allowing the control cabinet to be fully modularized and decentralized in line with the machine concept, with corresponding benefits for repair, maintenance, and operation. Across various industries and through comprehensive compliance (IEC, UL, CSA, etc.), there is growing interest in the MX-System worldwide. In conversations with customers, we witness the emergence of new and innovative machine concepts that would be impossible to implement using conventional methods, or only at considerable additional expense. Understanding of the MX-System has noticeably increased, as has the demand, with the latter serving as motivation to ensure we can deliver it in series next year.

Ever since it first launched, the component range of the MX-System has been continuously expanding. What have been the most important development steps or new components so far?

Marvin Düsterhus: Many machines have additional VPN routers installed in control cabinets, but this is not something we have in our own portfolio. Challenged with developing a solution, we came up with the infrastructure module, which is essentially an empty enclosure connected to our baseplate, with provisions for external connections. This allows various devices from third-party manufacturers to be seamlessly integrated into our ecosystem in a space-saving way. The family of power supplies has also expanded, notably in the case of the 48 V DC variants, for which we now offer high-performance models with capacities of up to 40 A. These have been specially developed with a focus on ATRO and XTS, but are also suitable for standard 48 V DC components. Another innovation is the capability to integrate pneumatics. This is where we provide electronic socket modules that can directly accommodate common pneumatic valves and can be mounted together on a baseplate. We have found this to be a highly cost-effective and space-saving solution, especially in applications with distributed or a limited number of valves, such as at the end-effector of a robot. Another major step for us is the introduction of size 3 for both baseplates and function modules, which we will unveil at SPS 2023.

Dr. Friedrich Klasing: The pneumatic modules were developed in cooperation with Festo and SMC, showcasing the successful integration of technologies from other manufacturers. The combination of the MX-System and pneumatics represents added value for all involved. It is enhancements such as these, with the corresponding added value, that will continue to enrich the spectrum of the MX-System in the future. The MX-System is set to bring about improvements in many areas of machine building, and documentation will play a crucial role in this regard. This is why we are pursuing an entirely new approach when it comes to compiling and preparing content. Who needs what information and when? This is the key question that we always keep in mind when preparing documentation. An indispensable component of the MX-System is the Beckhoff diagnostics app. While it is not the sole determining factor for the feasibility of a machine using MX-System resources, it will have a lasting influence on how machines are handled in the field. The app provides service technicians with access to previously inaccessible information, enhancing service quality while simultaneously cutting down on deployment time. What’s more, when used in connection with the features of the MX-System, it can also reduce downtime and boost productivity. The potential of the app is far from exhausted, and we are currently working on expanding it as a possible access point for off-site technicians. Another advantage of the Beckhoff diagnostics app compared to apps from other manufacturers is that it can provide information for the entire machine, not just individual components such as IO-Link devices.

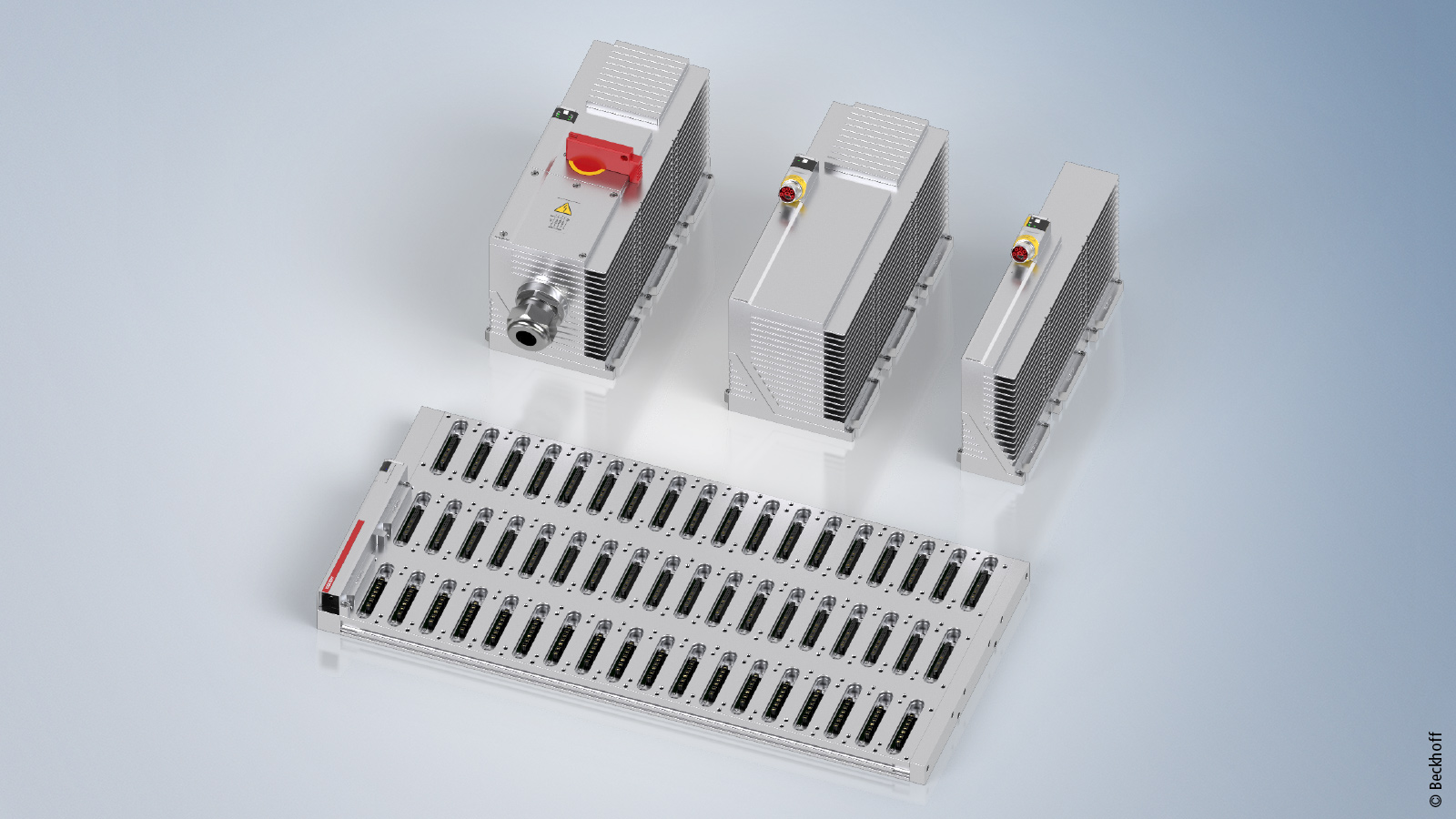

What are the characteristics of the new size 3 components unveiled at SPS 2023 and to what extent do they expand the range of applications of the MX-System?

Marvin Düsterhus: At its core, the baseplate is enhanced with an additional row of data slots, while all existing function modules of various sizes remain compatible. Besides its dimensions, the baseplate itself does not feature any new technical characteristics, but it does offer new possibilities: Without changing in width, there are now significantly more slots available to accommodate even more function modules. Moreover, the extra row allows us to use our new 3-row function modules. And thanks to the larger cooling fins, it is now possible to achieve not only 32 A power feeds, but also up to 125 A, and to switch significantly larger loads. In size 3, a servo drive can deliver up to 28 A nominal current per channel, and a frequency inverter can drive a motor with up to 15 kW.

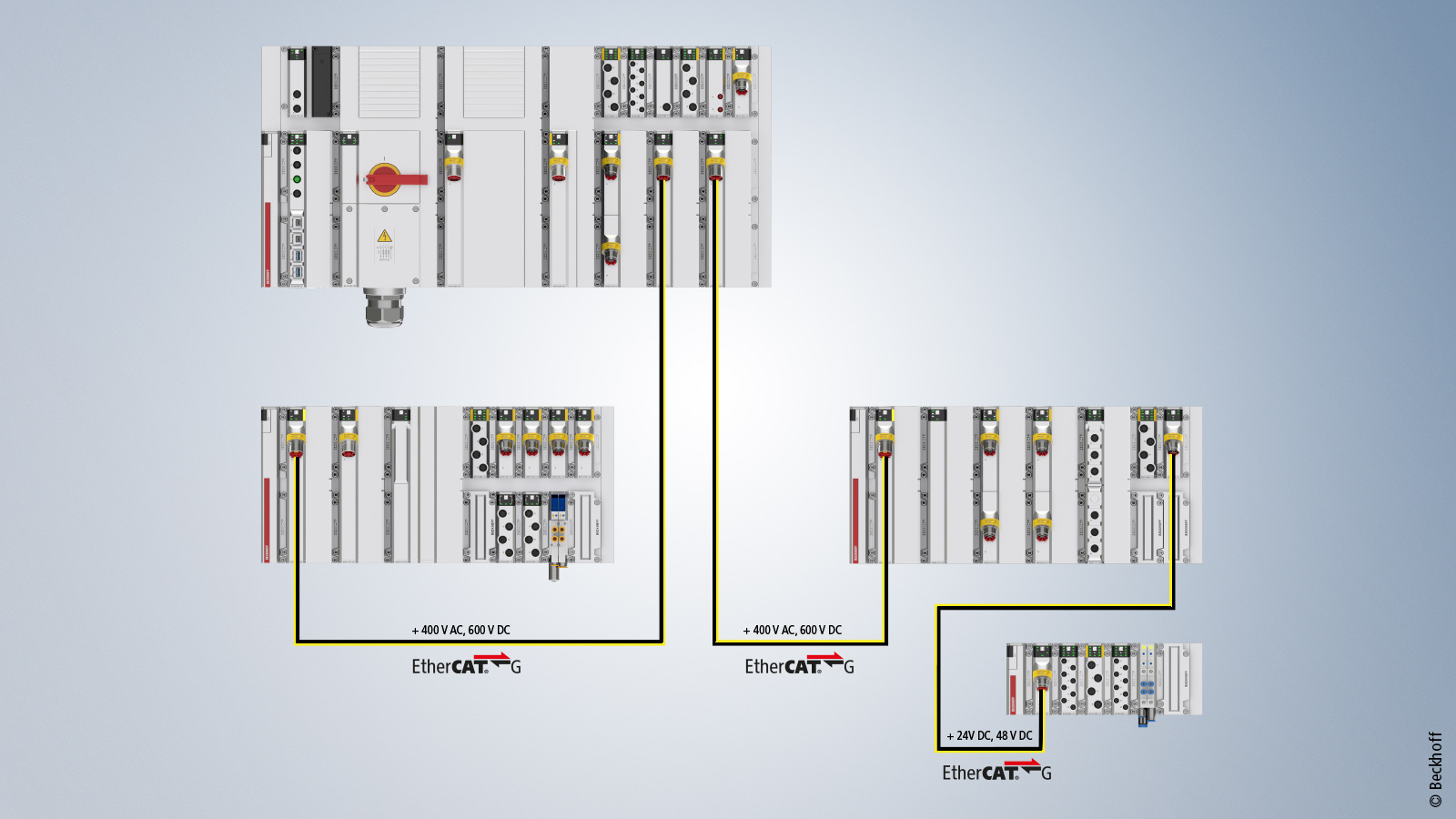

Dr. Friedrich Klasing: The focus here is less on integrating new functions and more on enhancing performance. The higher power levels in particular significantly broaden the application range of the MX-System. Up to now, machines requiring high power inputs could only be implemented to a limited extent and in a hybrid manner using the modular MX-System. The 3-row baseplates can replace the need for a control cabinet for power distribution in such cases, enabling more and larger machines to be designed on an entirely control cabinet-free basis, and thereby leverage the advantages of decentralized control technology. In the topology of a machine, a 3-row baseplate will likely always be positioned above the present 1- and 2-row baseplates, serving as a central point in a combination of star and daisy-chain topology.

A major advantage of the MX-System is the optimal support it provides for the increasingly popular machine modularization. How important is the expansion of the baseplate portfolio in this context?

Dr. Friedrich Klasing: The control cabinet will always stand in the way of a complete machine modularization in terms of both mechanics and electronics, as it always creates dependencies between different machine parts or else cannot be easily integrated into the machine room. A wide range of baseplates allows manufacturers to customize the required MX-Systems more easily to suit different machine modules. This contributes to the overall flexibility of this solution, as modules and components can be exchanged or added more easily. With the expansion of the baseplate portfolio and the associated increase in performance, even more machines can be implemented on a control cabinet-free basis. Excluding the typically larger modular machines, a 3-row baseplate can also serve as a more cost-effective alternative to two or more 1- or 2-row baseplates for a small monolithic machine with a relatively high number of 24 V DC components.

Can you illustrate the simplification of modularization and the potential savings in terms of the machine footprint with specific figures?

Marvin Düsterhus: This always depends on the application in question, as not all control cabinets are the same. There are many differences in dimensions, as well as in the installation location and position. Generally speaking, the MX-System reduces the required (screw-on) mounting space in terms of height and width compared to a typical control cabinet by about a third. The smaller modular units of the MX-System are much easier to integrate into the machine concept, allowing for a reduction in the overall footprint. To take a concrete example from the automotive industry, we looked at a machine with over 50 servo axes, whose entire mechanical section was already fully modular. The machine modules contained many decentralized I/O modules and some decentralized drives; nevertheless, there was still a 7-meter-long control cabinet on the side of the machine. This cabinet not only restricted machine accessibility, but also required all wiring from the machine modules to be routed there. By transitioning to the MX-System, the control cabinet was made completely redundant. In this case, a 3-row baseplate with a 125 A power supply was used, which feeds six additional MX-Systems as substations for the machine modules in a star configuration. Since the MX-Systems can be integrated into the machine modules without increasing the footprint, the floor space was reduced by approximately 10 percent as a result of getting rid of the control cabinet.

In addition to compactness, the cascadability of the MX-System is a crucial factor for consistent machine modularization. What concrete application advantages does this offer, particularly with regard to the expanded range of baseplates?

Dr. Friedrich Klasing: Cascading or daisy-chaining several MX-Systems is just one of the many possible topologies for replacing a control cabinet with several MX-Systems. In addition to chaining several MX-Systems through a single cable, MX-System stations can also be used like a hub. This means that multiple MX-System stations are supplied with both power and EtherCAT from one (central) baseplate either in parallel or serially. Regardless of whether multiple MX-Systems are cascaded or connected in a star topology, the limiting factor here is power. This is where the 3-row modules make a big difference, as they facilitate a power supply of up to 125 A AC from the mains. What’s more, the use of central DC link modules for generating the 600 V DC intermediate circuit voltage can be implemented more effectively in size 3 compared to size 2.

Benefits of the MX-System

Modularity for future security:

- Market demand: As end customers increasingly prioritize flexibility in their production processes, the demand for modular machines and systems is on the rise.

- Decentralization: The MX-System optimally supports modularization as a machine-mountable, decentrally distributable solution.

- Flexibility: The MX-System can be cascaded in a highly flexible manner and combined with existing control cabinets and IP67 field components.

Maximum efficiency for machine building:

- Engineering: MX-System function modules simplify project planning, minimize the number of components, and reduce parts lists by up to 80%.

- Market expansion: The MX-System is IEC, UL, and CSA compliant, making it a globally compatible solution.

- Mounting: The straightforward process of attaching and screwing in the function modules replaces the need for complex mechanical effort and reduces the risk of wiring errors.

- Shortage of skilled workers: The low engineering effort and fast assembly (e.g., 1 hour of working time instead of 24) eases the burden on skilled workers and opens up potential for less qualified personnel.

- Service: Faults are easier to diagnose and components are easier to replace.

Increase in productivity for the end user:

- Optimal space utilization: The eliminated need for a control cabinet minimizes the machine footprint and optimizes the available production area.

- Flexibility: Modular machines facilitate commissioning and integration into existing production facilities.

- Service: EtherCAT and hot-swappable MX-System components result in optimal diagnostic capabilities and the fastest possible replacement.

- Inventory management: Highly functional, reusable modules minimize spare parts inventory.