2020 is a year of anniversaries for Beckhoff

Author: Ronald Heinze

Published in Open Automation 06/2020, VDE Verlag, www.vde-verlag.de

Founded 40 years ago, the company started out with PC-based controllers in 1985 and launched its bus terminals in 1995. Ronald Heinze, editor-in-chief of Open Automation, talked with managing director and founder Hans Beckhoff about the company’s many innovations.

“We view the current economic situation as acceptably positive,” said Hans Beckhoff. “As an enterprise that has been spoiled by growth, we can look back on annual growth rates of 15% on average since 2000.” This kind of growth could not be achieved in 2019, however. Starting in mid-2018, says the managing director, a strong decline in orders became apparent, especially from regular customers in the mechanical engineering industry. Beckhoff is nevertheless happy: “With €903 million in sales, we were just 1% below the previous year’s level, which is an acceptable result under the prevailing conditions.”

Beckhoff China accounts for 20% of total sales, with machines for the production of solar panels, wind turbines and general machine building being the main success factors. Sales vary from country to country in 2020. China is positive, while sales in Europe without Germany, Austria and Switzerland are steady. In Germany, however, sales are declining by a single-digit percentage. The main reason for this is the capital goods sector. The machine building industry is suffering due to developments in the automobile sector and the global declines caused by the coronavirus crisis and global trade tensions. The building sector, on the other hand, is still going strong, also in Germany. “At the end of the day, this is leading to less growth than what we have been used to in recent years,” says Beckhoff.

Growth despite the coronavirus crisis in 2020

“During the coronavirus crisis, our production and our ability to deliver never suffered,” says Hans Beckhoff. “We never operated with reduced work hours, and we don’t plan to. We are operating at full capacity. Subject to the developments in recent weeks, we expect to finish the year with a small increase of 2% and total sales of roughly 920 million euros,” says Beckhoff. New customers made up for crisis-related declines among traditional Beckhoff customers.

“We are sticking to our planned investment program irrespective of the coronavirus,” the managing director points out. The company continues to expand its production area for drive technology by tripling the current floor space. In addition, integrating lean manufacturing concepts with shorter travel paths, more efficient material handling and new workflows will make the production significantly more efficient. Hans Beckhoff: “Scaling up the production of electronic drive components will be a major aspect of our growth in the coming years, both in classic rotatory and linear drive technology and in alternative linear kinematics such as our XTS multi-mover transport system and our sixdimensional XPlanar hovering multi-mover transport system.”

40 years of success

40 years is a remarkable anniversary in automation technology. Hans Beckhoff started his business in 1980 as a one-person operation in a small storage space where he built control cabinets for customers of his parents’ electrical installation business. The trained nuclear physicist quickly recognized the impending triumphant advance of microelectronics and began to develop microprocessor-based positioning electronics which he combined with the control cabinets as system solutions for customers in the window and woodworking machine segment. The storage space became a garage in which electricians from his father's electro-installation business often helped out, and from the garage he moved into the first building of his own in 1984. During its first years, the business operated as a system integrator of electronics that were partly developed in-house. “Things changed in 1986 with the development of our PC-based control technology. We recognized that this technology could form the basis for a complete automation system consisting of CPU, I/Os, drive technology, software and IT functions. This combination of properties put us a long way ahead of the competition, and so we decided in 1990 to exhibit our products for the first time at a trade fair, the Hannover Messe,” Hans Beckhoff remembers. “We were control technology revolutionaries with a philosophy that was distinctly different from that of traditional automation system manufacturers. Progressive and dynamic customers found this exciting, but tradition-oriented customers rejected it. Our first trade fair was exciting, and I am pleased to say that today’s trade fairs and exhibitions are equally exciting. What also has not changed is that it is still the innovative customers who come to us and share our enthusiasm.”

The first decade of Beckhoff Automation was characterized by specialty sales. In the 1990s the company began to build a more general sales organization for automation devices in Germany. The global expansion of its sales began in the new millennium. “Today we have 22 offices in Germany and are represented with our own subsidiaries in 39 countries and in 75 countries overall,” says Beckhoff.

While the entrepreneur soldered the first parts himself in the beginning, today his factories churn out parts by the millions. “Today we can look back on 40 years of company history with sales that grew from 50,000 marks in the first year to 900 million euros, a headcount that went from one to 4,300, and technology that went from an 8-bit microprocessor running at 4 MHz to 48- kernel/64-bit models running at 4 GHz. While our company is constantly changing in terms of its products and its organization, we still feel a bit like a start-up that may be 40 years old and a little larger but is still characterized by the absolute joy of turning the world upside down with new technologies.”

“Innovation is a constant necessity also in the area of sales and distribution, and we are missing the trade fairs as a place where customers can meet us in person,” continues Hans Beckhoff. “Fortunately, platforms like Microsoft Teams give us the opportunity to engage with customers even more intensively no matter where they are.” The company uses live presentations and its online Automation Updates to communicate important technical innovations to its customers and stay in touch with them.

“We are introducing new products at the virtual SPS Connect trade fair and our own online events while also illustrating the functional system concept of our PC-based control philosophy,” explains Beckhoff. “At Beckhoff, automation technology means providing a consistent platform that ranges from affordable mini-controllers to multi-core high-performance CPUs, EtherCAT-based I/O bus terminals, drives and sensors, ultra-fast and in some cases highly complex PLC functionalities with deeply integrated safety functions for workflow and motion, as well as multi-axis motion functions ranging from simple point-to-point travel to 5-axis CNC and robotic kinematics to innovative mover-based linear kinematics. All of this is supplemented by precise measurement technology that is integrated into the control functions, real-time C++ high-level language programming, real-time integration of MATLAB®/Simulink® functions, integrated real-time image processing, ready-to- use artificial intelligence and outstanding integration of edge- and cloud-based Industrie 4.0 functions. This comprehensive automation platform is the result of 40 years of innovation and experience as well as 40 years of joint projects with our customers.”

Machine learning and cloud activities

One special focus area this year is the completion of the first products in the field of machine learning. “We began to actively involve ourselves in artificial intelligence (AI) four years ago,” says Hans Beckhoff. “We learned the basics of this fascinating technology, developed it, and adapted it to automation applications. We are especially proud that our ML inference environment runs in real time within the PLC context. This opens the door to many new control capabilities that we are now making available to our customers as an integrated component of TwinCAT.”

Cloud-based engineering is in the internal testing phase, says Hans Beckhoff: “Cloud-based engineering makes it easy to use engineering tools on a virtual machine in the cloud instead of directly on a laptop.” Via an internet browser, cloud-based engineering becomes accessible from all kinds of devices with any operating system without having to install anything. “It will be released as a product by the end of this year,” says Beckhoff.

Reservations against cloud-based computing are unfounded in this case since the source code does not necessarily have to be stored in the cloud, which makes it not only convenient but also very safe, says the managing director, because the large cloud providers support this approach with corresponding services in the form of repositories (Git). “We are working closely with Microsoft and Amazon Web Services in this field,” he adds.

There are also many innovations in Beckhoff’s TwinCAT software with new libraries for XPlanar and new controls for TwinCAT HMI. Beckhoff controllers feature many open interfaces, with some new ones now being added to communicate with Siemens equipment. As a result, the system can now be linked with MindSphere®, the Industrial IoT as a service solution from Siemens. Beckhoff also implemented a new TwinCAT-to-S7 communication capability.

Beckhoff is also an active supporter of the GAIA-X initiative. “The goal is to define a standardized interface for data services from the underlying cloud solutions,” explains Hans Beckhoff. “GAIA-X aims to be the European answer to the predominance of American and Asian hyperscalers. We think that this approach will also be useful for applications in automation technology.”

Momentum for the process industry

Beckhoff Automation has also been active in the process industry for quite some time with its PC-based control technology. For example, the FDT/DTM interface has been an integral part of TwinCAT for several years. “It is used to configure our HART products and integrate them into other systems,” explains Hans Beckhoff. “With our TwinCAT MTP (Module Type Package), we are now taking the next big step into the process industry.” The package is used to easily integrate modules that are governed by Beckhoff controllers into OPC UA-based process control systems. That way, TwinCAT-automated system modules can be easily integrated into total systems via the export function in TwinCAT MTP.

“The trend toward modular automation in process technology underscores the advantages of our PC-based control technology,” says Beckhoff. The fine scalability of the controllers allows the module manufacturer to pick the controller that works best with the respective module. TwinCAT MTP will be released by the end of this year. Pilot projects are already underway.

A plethora of innovations in IPC technology

After 35 years of IPC technology from Beckhoff, users can once again expect many exciting innovations this year. The fact that CPU manufacturers are increasingly taking industrial applications into account in their designs gives the German automation specialists additional tailwind. They offer programs for long-term availability and specially integrated functions such as the timing control of internal buses and TSN-based Ethernet controllers on a chip.

The successful C60xx family of ultra-compact IPCs is being expanded. The fanless C6025 Core-i-based computer will be released by the end of 2020 with new ‘Whiskey Lake’ processors from Intel. “While these computers feature outstanding automation properties, they can also be used as powerful and compact edge devices,” says Hans Beckhoff.

“The new C7015 with IP65/67 rating opens up new ways of integrating the IPC directly into the machine,” says Hans Beckhoff about the next innovation. The new model is based on Intel’s ‘Apollo Lake’ Atom® processors, and the integrated EtherCAT P master provides additional I/O links to the field. With its extensive interfaces and powerful Intel Atom® multi-core technology, the IPC is ideal for automation and cloud communication tasks. “With this IPC, EtherCAT P and IP65 I/O box modules, you can easily implement a complete data collection system, and you don't need a switching cabinet,” says Beckhoff.

The C6030 and C6032 computers with forced ventilation as well as all IPCs with ATX and 3½-inch motherboards will be equipped with Intel® Core™ i8/9 ‘Coffee Lake/Coffee Lake Refresh’ processors, which makes it possible to implement high-performance automation systems with a single IPC with up to eight kernels. “Users like these computers because of their high level of performance,” adds Beckhoff. “Taking advantage of their multi-core technology with the core isolation function in TwinCAT 3 is becoming increasingly important even in relatively simple applications.”

The new CX20x3 family of embedded PCs will now be equipped with dual-core or quad-core AMD Ryzen™ CPUs. “Due to their outstanding real-time properties and their support of 32-bit and 64-bit systems, i.e. of TwinCAT 2 and TwinCAT 3, these computers are ideally suited for all automation tasks,” says Hans Beckhoff. “With AMD, an ‘old’ player who is currently re-shuffling its line-up is re-entering the field.” Beckhoff expects this to trigger a growth push for computer systems in the industrial environment since segments like edge computing, fog computing, cloud computing, machine learning, AI and vision are currently finding their places and expanding their application areas in addition to established PC-based controllers.

With the introduction of the CU81xx family of systems, uninterruptible power supplies (UPS) are now available for all IPC/CX/panel products. They feature a flexible communication link either via the UPS-OCT one-cable solution for 24 V DC power and data or separately via a USB connection.

Another innovation is the CX7000 controller platform based on the ARM Cortex™-M7 processor. For a list price of less than 200 euros, it provides a powerful TwinCAT 3 PLC with integrated I/Os and a LAN port. Via the EtherCAT interface, the PLC can be expanded almost at will with all Beckhoff Bus Terminals and connected to the wide world of EtherCAT devices. According to Hans Beckhoff, the CX7000 is a true ‘wunderkind’ in terms of price and performance. “We make increasingly powerful solutions available to our customers at ever lower prices,” says the managing director, “which constantly expands the diversity of applications in automation technology.”

The fact that Beckhoff now supports TwinCAT/BSD as an alternative operating system for all IPC platforms should no longer come as a surprise. It combines the TwinCAT runtime with FreeBSD, an industrial, Unix-compatible open-source operating system that requires no GPL license. Hans Beckhoff considers it an alternative or successor to Windows Embedded Compact 7 (CE7). It might even replace ‘big-Windows’ applications in the future, i.e. applications running under Windows 7 or 10. By supporting ARM CPUs as well as Intel® Xeon® Processors, FreeBSD – and TwinCAT/BSD, accordingly – supports scalable platforms ranging from small embedded to high-performance IPC controllers. According to the general manager, this puts his company “on the same page as Microsoft, which increasingly supports Unix variants in addition to Windows.”

The subject of HMI also has not lost any of its attractiveness for Beckhoff as a company. “We respond to new customer requirements every day and build panels and panel PCs that are optimally matched to the respective application,” says the managing director. Customers can even use a configurator to adapt the key extension of individual units to their particular application. Starting back in 2012/2013, Beckhoff was one of the first large industrial automation providers who made multi-touch technology available for industrial applications, thus starting a new trend in the industry. Many large and small companies have rushed into the IPC segment since then. “Our know-how, our manufacturing depth and most of all our close customer relationships enable us to develop and offer modern industrial PC hardware that's performance- and price-optimized,” says Hans Beckhoff.

Bus/EtherCAT Terminals – basic building blocks for automation

The managing director remembers: “In 1995, i.e. 25 years ago, we presented our bus terminals at Hannover Messe. They represented a real revolution for the entire automation industry at the time, because until then only fieldbus block I/Os with 8 or 16 or 32 I/Os were available. Our bus terminals combined the proven terminal strip design with modern I/O and communication technology. This enabled a granular structure of the terminal bar directly in the terminal box in accordance with the desired signal mix. It also eliminated an entire wiring layer in many applications and made the terminal boxes smaller and the entire I/O station more affordable. At the time, we called the bus terminal a new basic building block of automation technology, just like the contactor. And that was important because virtually all automation technology manufacturers picked up and copied our design. Today, the bus terminal is available everywhere as a standard I/O component. Unfortunately, we did not properly protect this idea with a patent at the time... The bus terminal system is also a good example of joint development work by a medium-sized company. Beckhoff was already a pretty solid hardware and software company back then, but we had little experience with electromechanical housing designs. In Wago we found a partner who took over these electromechanical developments. Both companies contributed their specific know-how to the project, and both introduced the product to the market and became successful with it. A wonderful example of becoming better by working together!”

Today, Beckhoff offers more than 1,000 variants of its bus/EtherCAT Terminals for almost any type of signal and any application. The system has been steadily expanded over the years. In addition to terminals for standard automation signals, the company offers many communication terminals, measurement terminals, ‘yellow’ safety terminals, ‘blue’ Ex-i (explosion-proof) terminals, motor control terminals and many more. Hans Beckhoff: “We are especially pleased that we kept the design of our terminal system stable for 25 years. Almost all the terminals we introduced at the beginning in 1995 are still available as regular Beckhoff products. We understood early on that long-term availability is a great asset for our customers. Of course, we regularly introduced new designs for all kinds of signals to improve performance and pricing, but we maintained the general compatibility and will continue to do so. The bus terminal system has been around for 25 years now, and we think that we have another 25 years ahead of us.”

The managing director adds: “EtherCAT is another basic technology invented by Beckhoff that is now recognized and used all over the world. Since it was introduced to the public in 2003, it is not celebrating an anniversary this year.” Still, Hans Beckhoff is proud that the standard has remained stable since its introduction and that EtherCAT continues to be the reference for high-speed, deterministic, easy-to-handle and affordable communication technology in the control sector. “Compatible with EtherCAT, we have also introduced EtherCAT G and EtherCAT G10, i.e. the 1 Gbit/s and 10 Gbit/s variants, which means that more than sufficient performance reserves are available for future applications.”

According to the managing director, EtherCAT offers everything you need to supply an easy-to-use yet high-performing communication solution at the I/O level. “We are actively supporting the development of TSN with many resources,” says Hans Beckhoff. “TSN is particularly suitable for combining different controllers.” For the I/O level, however, “the complex switching technology of TSN requires too much unnecessary overload,” so it is therefore not solution oriented.

Among the many innovations in the I/O field, the new ELM72xx family of servo terminals stands out. Its metal housing makes it possible to double previous loads to up to 1,000 watts of drive capacity. In addition, STO/SS1 and brake chopper control are integrated by default. And as an option, the extensive Safe Motion package is available with functions like Safe Limited Speed and Safe Position. Two-channel servo drive terminals can therefore offer significant cost benefits. Four- and eight-channel thermo element terminals of the ELM33xx series expand the portfolio in the segment of high-precision measurement terminals. And the new EL51xx for evaluating 5 V incremental encoders (RS422/ TTL) cuts the cabinet space requirement in half.

Beckhoff’s engineers are also excited about Single Pair Ethernet (SPE). “We consider SPE to be a very useful development,” says Hans Beckhoff, especially from a process technology perspective. Much of its success will depend on the availability of field devices. The integration of intrinsic safety for explosion protection opens the door to new concepts with lower wiring costs, improved diagnostics, and the ability to have plug-and-play mechanisms for the installation of field devices. “We are a great proponent of one-cable technology, which is why we introduced EtherCAT P four years ago,” Beckhoff continues. “We see the development of SPE in a similar light. Especially in applications with lower data rates, this is a field in which EtherCAT can score points with its protocol efficiency.”

Power supplies as system components

“Every automation solution requires a power supply,” says Hans Beckhoff. “In the past we did not have them in our portfolio, but we have changed that now.” Having a reliable supply of 24 V or 48 V power for automation products is a prerequisite for a trouble-free and long-lasting operation. Beckhoff has plenty of experience in interacting with power supplies for compact drive technologies and the XTS system, for example. Having a solid interaction with the power supply is also critical for the operational reliability of IPCs and electronic overcurrent protection devices in terminal format (EL922x).

“We are now making the extensive experience we have already gained available in the form of a broad portfolio of one- and three-phase power supplies with our PS1000, PS2000 and PS3000 series,” says Beckhoff. The power supplies are optimally matched to the company’s automation components and are highly efficient. “As a system provider, we will now be able to provide our customers with comprehensive advice and appropriate solutions also in the field of power supplies,” emphasizes the graduate physicist.

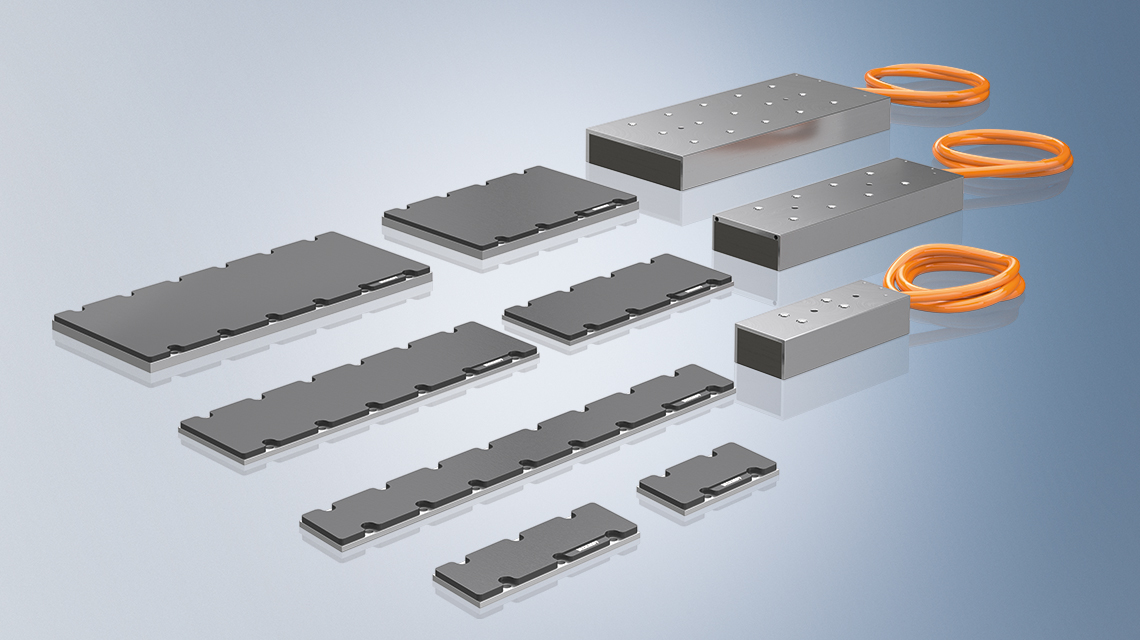

More drive for highly dynamic positioning tasks

Together with its growing subsidiary Fertig Motors, Beckhoff has developed a new generation of powerful linear motors that are already available in volume. The AL8000 product family is based on a modular system of linear motors and magnetic plates. The user can choose from three widths: 50 mm, 80 mm and 130 mm. “Our product family, which is developed and manufactured entirely in Germany, covers a wide range of forces from 120 to 6,750 N and offers maximum scalability for optimized stator lengths,” says Beckhoff. “We can put together the best possible motor for each customer.” The motors can be configured with the Motion Designer tool, which is also used for our rotary motors.

The AX8000 servo system has been expanded by the two combined power supply and axis modules AX8540 and AX8525. As a result, the product line now includes axis controllers with up to 40 A of continuous current for highload applications. The modules can be connected to additional axis modules. IP65-rated AMP motors with integrated power amplifiers are already being used in real-life applications with great success. “We are currently expanding the production of the AMP modules since we expect the interest in these products to be high,” adds the managing director.

The linear XTS transport system is also progressing well. “We are winning many new projects in a wide range of markets,” says Beckhoff. Here, too, the company has some innovations to report: The movers can now generate forces of up to 200 N, which opens the door to new applications. In addition, with the ability to build L-, U- and T-shaped tracks, almost any track design is now possible. “In combination with positive and negative radii, this gives the movers maximum freedom,” adds Beckhoff.

Also very positive has been the response to Beckhoff’s XPlanar technology with its floating movers for contactless travel. “Our technology is being used in many industrial fields and even for some applications that we never dreamed of, for example as a presenter for luxury watches,” says Beckhoff. The system now supports three mover sizes, and automatic mover detection is possible even when they are removed during operation. Another new function is track management, which makes it possible to use multiple tracks simultaneously and separately from each other. Movers can also be linked together mechanically.

In light of so many innovations, the managing director is optimistic about 2021: “Our customers in the high-volume machine building industry will recover, and let's not forget that we are also adding new customers all the time.” After all, the company's innovations are constantly opening up new application areas and helping users to improve their machines and systems for the long term. “As long as companies want to churn out more products more efficiently, there will be a need for us,” he concludes.