Many users – and especially those in price-conscious and emerging markets – require reliable drive solutions with an optimized price/performance ratio. The new economy drive system meets this need without compromising on performance or quality.

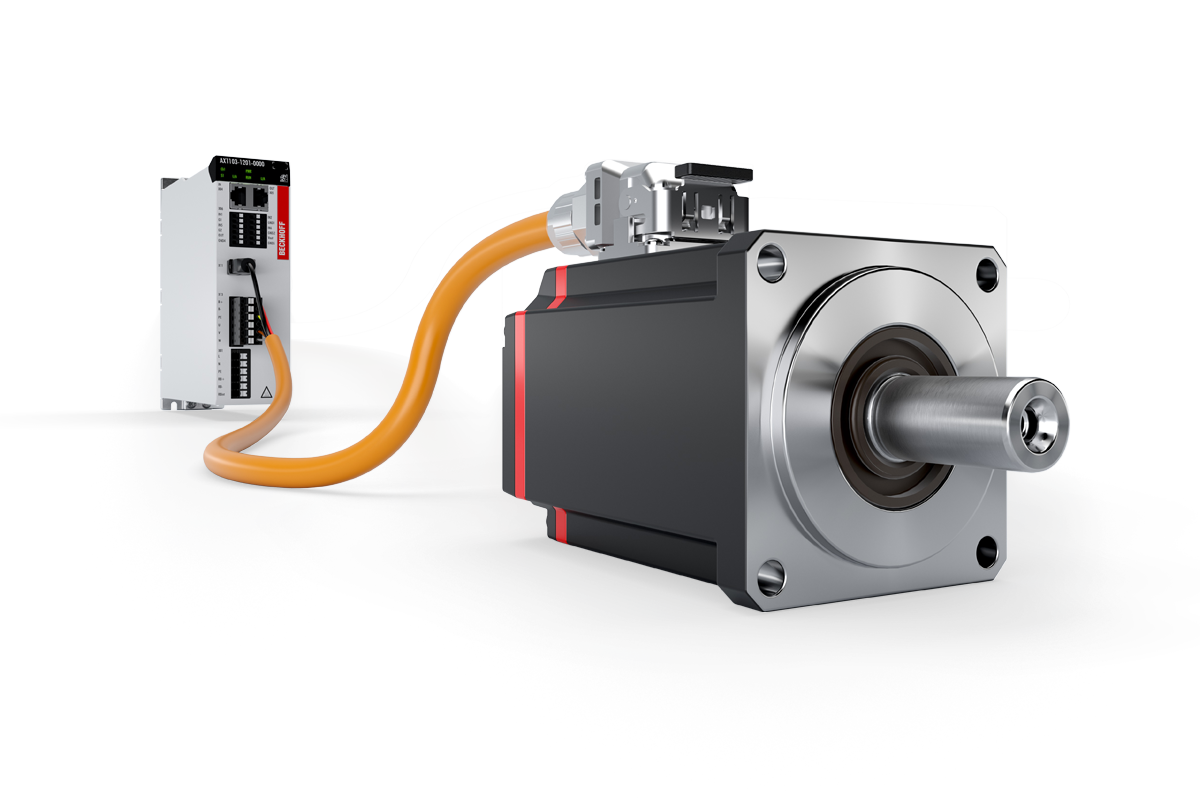

The AM1000 economy servomotor in combination with the AX1000 economy servo drive forms a powerful, space-saving, and ideally matched servo drive system. In addition, the AF1000 economy variable frequency drive adds compact, versatile drives for simple applications to the portfolio.

Get ahead with the economy drive system:

- optimized price/performance ratio

- takes up minimal space in the control cabinet and machine due to compact designs

- available as a single-axis or highly cost-effective dual-axis version

- convenient design, commissioning, and diagnostics with TwinCAT

Our product series at a glance

Economy servomotor

Economy servo drive

Economy variable frequency drive

The high-performance servomotor for dynamic positioning tasks is available in three flange dimensions of 40, 60, and 80 mm with a power range from 50 W to 1.7 kW. The highly compact motor meets the highest technological demands with an optimized price/performance ratio. In combination with the AX1000 economy servo drive and One Cable Technology (OCT), users benefit from a perfectly coordinated servo drive system with simple plug-and-play commissioning.

All the advantages at a glance:

- space-saving machine integration due to extremely compact design and high power density

- extremely simple commissioning and minimal cabling work due to OCT

- can be used worldwide due to optimized winding design for all power supplies up to 480 V AC

- robust design with compact metal connector

The AX1000 economy servo drive is a highly cost-effective series in the rated current range from 1.65 to 12 A and delivers outstanding performance. The AX1000 is available for single-phase infeeds with 1 x 230 V AC and, in the higher power range, for three-phase infeeds with 3 x 400 V AC – as both single and double-axis versions. The devices are perfectly integrated into TwinCAT via EtherCAT and support AM1000 and AM8000 series servomotors as well as asynchronous and reluctance motors.

All the advantages at a glance:

- small form factor makes it easier to use small installation spaces

- no external power supply required due to internal 24 V generation

- optional TwinSAFE Safe Motion functions available

- convenient design, commissioning, and diagnostics with TwinCAT

With the AF1000 economy variable frequency drive, Beckhoff now offers a cost-effective solution for basic drive applications including conveyor systems, pumps, and fans. The compact, highly integrated devices are suitable for implementing drive axes with synchronous, asynchronous, and reluctance motors without a feedback system. The AF1000 can be operated on single-phase power supplies with 1 x 230 V AC and, in the higher power range, on three-phase power supplies with 3 x 400 V AC and outputs from 370 W to 5.5 kW.

All the advantages at a glance:

- small form factor makes it easier to use small installation spaces

- particularly cost-effective as a dual-axis module

- convenient and complete integration into TwinCAT as an EtherCAT device

Highly optimized and fully system-integrated: AM1000 and AX1000 as a servo drive system

The AM1000 series of highly dynamic servomotors are designed for use with the AX1000 economy servo drive. In combination with One Cable Technology (OCT), users benefit from a perfectly coordinated servo drive system with simple plug-and-play commissioning. This cost-optimized and space-saving servo system is available in various power output ratings up to 1,000 watts (230 V AC) or 1,700 watts (400 V AC). With EtherCAT and seamless integration into TwinCAT, commissioning, tuning, and diagnostics are particularly easy.

The AM1000 economy servomotor and AX1000 economy servo drive provide users with an ideally matched and optimized servo drive system. Featuring a design that has been optimized with a view to both production and cost, this combination delivers an outstanding price/performance ratio without compromising on performance or quality.

Due to plug-and-play with OCT and a simple choice of power sizes, the work involved in dimensioning, installation, and commissioning is significantly reduced. In addition, the low variance results in further cost benefits for warehousing and spare parts.

The optimized components of the economy drive system significantly reduce the space required in both the control cabinet and the machine. In addition to the extremely compact design, the connection technology on the front offers simple, space-saving wiring and an installation-friendly system structure with no gaps between the devices – ideal for minimizing the control cabinet footprint.

The extremely compact AM1000 servomotor with its space-saving wiring also ensures maximum space efficiency in cost-sensitive automation solutions, particularly as a result of its extremely short overall length and very high power density.

With One Cable Technology (OCT), the feedback signals are transmitted directly via the cable to the power supply so that the power and feedback systems are integrated in a single motor connection cable. This significantly reduces cabling work and material costs. The economy drive system with the AM1000 servomotor in combination with the AX1000 servo drive also offers the option of using partially shielded cables, which further reduce the work involved in installation due to their small diameter and high degree of flexibility.

The OCT-based electronic nameplate integrated in the AM1000 enables the AX1000 to read and automatically configure the connected motor. This significantly simplifies and speeds up commissioning of the economy servo drive system – for efficient and error-free system integration.

The economy drive system is fully integrated into TwinCAT and the proven motion software products. Our innovative software solutions efficiently and intuitively support the entire motion engineering process, from initial dimensioning with the TwinCAT Motion Designer and commissioning with the TwinCAT Drive Manager 2 to automated optimization with TwinCAT Autotuning. This ensures maximum performance and easy handling in every project phase.

Performance-based product overview – identify the ideal solution for your application quickly and easily

Products

AM1000 | Economy servomotors

The AM1000 servomotors meet the highest technological demands with an optimized price/performance ratio for cost-sensitive applications.

AX1000 | Economy servo drives

The AX1000 economy servo drive for implementing demanding and cost-sensitive drive tasks.

AF1000 | Economy variable frequency drive

The variable frequency drives in the AF1000 series are particularly suitable for performing basic drive tasks cost-effectively.