Interview about new linear motor series

Published in A&D 04/2021, publisher: publish-industry Verlag, www.publish-industry.net

The interview was conducted by Christian Vilsbeck, A&D.

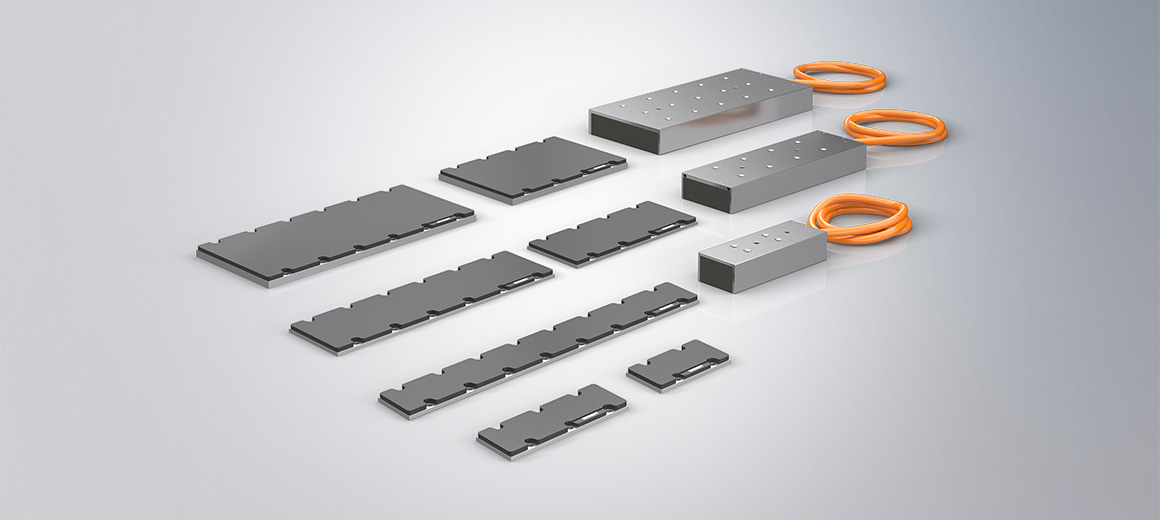

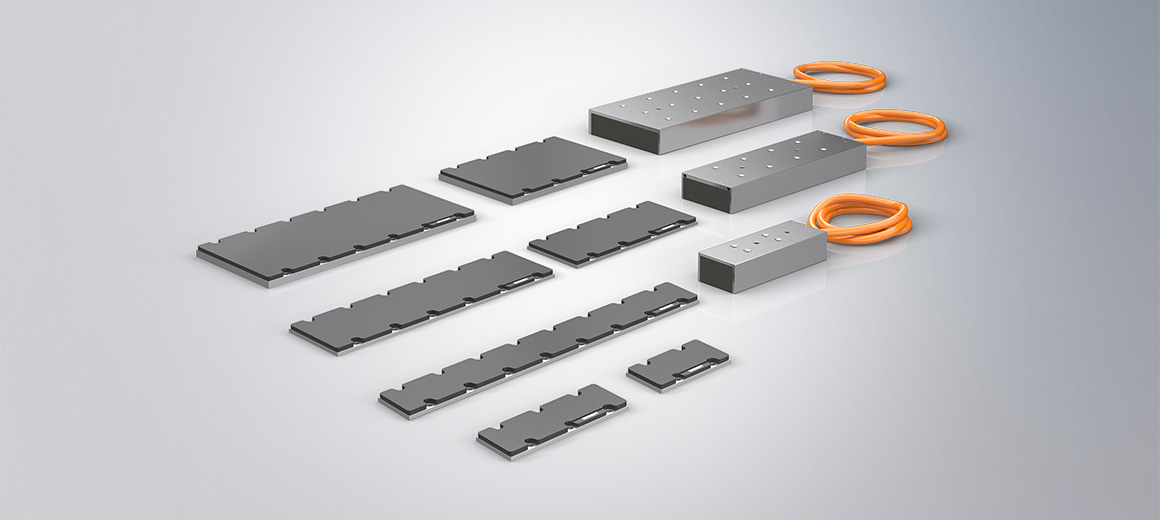

With the AL8000 series, Beckhoff offers modular linear motors with the quality label "Made in Germany". In an interview with A&D, Angela Vogt, Product Management Drive Technology at Beckhoff, explains what is possible with these linear motors.

Linear motors are characterized by high positioning accuracy and dynamics. For which applications is the AL8000 product family particularly suitable?

The highly dynamic and compact AL8000 devices are ideally suited for applications in metal working such as laser cutting or welding machines, in packaging machines, printer applications and machining centers as transport and positioning axes, among others. Ultimately, any application with stringent demands for precision or dynamics is worth considering, since in such cases translatory drive mechanisms with rotational drives are not suitable due to the elasticity or play of the drive mechanisms.

The AL8000 series is generally cooled by convection, but certain models have water cooling. When is this necessary?

Water cooling is used to optimally dissipate the heat from the coil part to the cooling medium, rather than the environment. This is particularly advantageous in situations where the workpiece could be unintentionally deformed by heat input, which would make precise machining impossible. Another advantage is higher performance: with water cooling, the thermal resistance to the cooling medium is significantly lower compared to convection, so that the motor can be operated with higher output. Water cooling is optional for the widest models of the AL8000 series and standard for the medium width models, offering users flexibility.

The AL8000 series is based on a modular design. Do you also offer customization options?

The modular design of the AL8000 linear motors gives us certain freedom in production and facilitates customer-specific adaptations. Since each coil part consists of several identical stator segments, we can relatively easily vary the length of the coil part up to a maximum number of coils. If the customer has additional requirements, such as the use of a custom winding, this can also be implemented through close cooperation with our development and production facility in Germany.

What does the future roadmap for Beckhoff's linear motors look like?

After the successful sales launch over the last few months, we have many plans for our new product series. We are already working on further development steps and are simultaneously pursuing several new functions and features for our AL8000, so we will have plenty to report next year. In addition to the AL8000, Beckhoff will expand its translatory drive portfolio to include tubular motors and electric cylinders.