Automation for sustainable packaging technology

Source: Fluid – Das unabhängige Technikmagazin (the independent technology magazine), Verlag moderne industrie GmbH, www.fluid.de

Author: Iris Lindner

We need to change the way we design and produce packaging. This involves implementing both environmentally friendly materials and advanced production technologies. Because although packaging is still largely responsible for our mountains of waste, it is an essential part of our daily lives. It contributes to hygiene in all social sectors and is one of the reasons for our high standard of health. It has also significantly improved logistics as well as the shelf life and availability of many different products.

Sustainable materials and resource-saving technologies

To produce a product that is truly sustainable, the entire process chain must be designed in a way that is efficient and conserves resources – starting with raw materials, energy metering in production, and packaging materials, through to factory automation and logistics. This means that companies need to step out of their comfort zone and embrace the concept of disruptive innovation. As a result, the communication process between end customers, machine builders, and automation companies is essential to ensure that they all work together to implement sustainable projects and conserve resources. Equally, new recycling concepts are just as important as developing environmentally friendly packaging materials. Materials scientists and engineers need to develop new packaging materials and technologies to embed a sustainable approach in the packaging industry.

Automation minimizes the use of resources

But how can an automation company contribute to the sustainable use of resources? The answer to this question is simple: Automation technology makes it possible to meet the ever-increasing demands of the world’s growing population with fewer and fewer resources. This principle is more topical than ever, because most raw materials on our planet are finite. Recycling must therefore play an even greater role and be used more efficiently in the future. This also requires machines that are adapted to future technologies and capable of processing new packaging materials. As a result, many different processes, technologies, and materials come into play. Moreover, we must not forget approaches such as additive manufacturing, e.g., CLIP (Continuous Liquid Interface Production) or bionic fuel cells, as well as GreenTech and artificial intelligence.

Efficient Beckhoff technology

Beckhoff first presented its XTS intelligent product transport system as a completely innovative product at the interpack trade fair back in 2011. Ten years on, it is impossible to imagine the world of packaging machine builders without our technology. More than 1200 XTS applications have been installed since then.

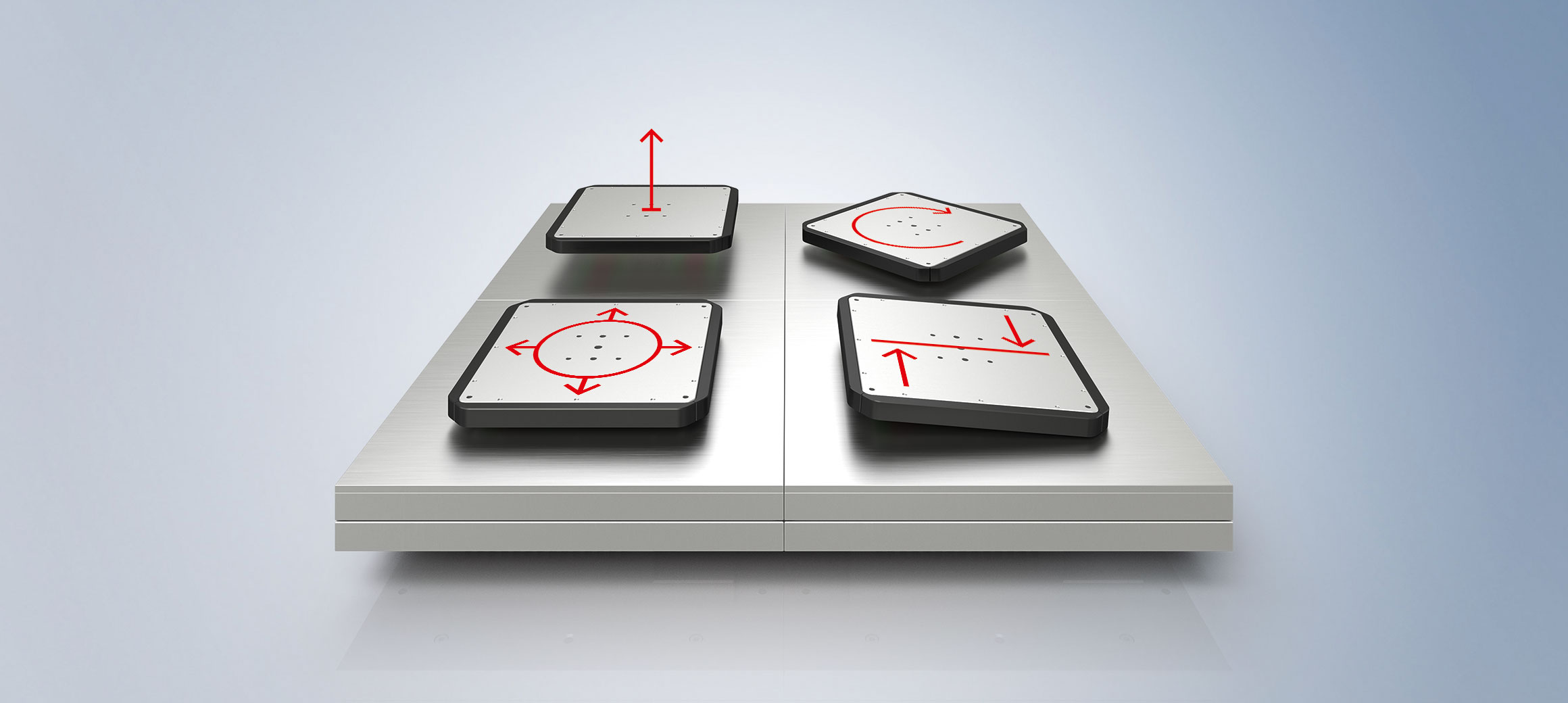

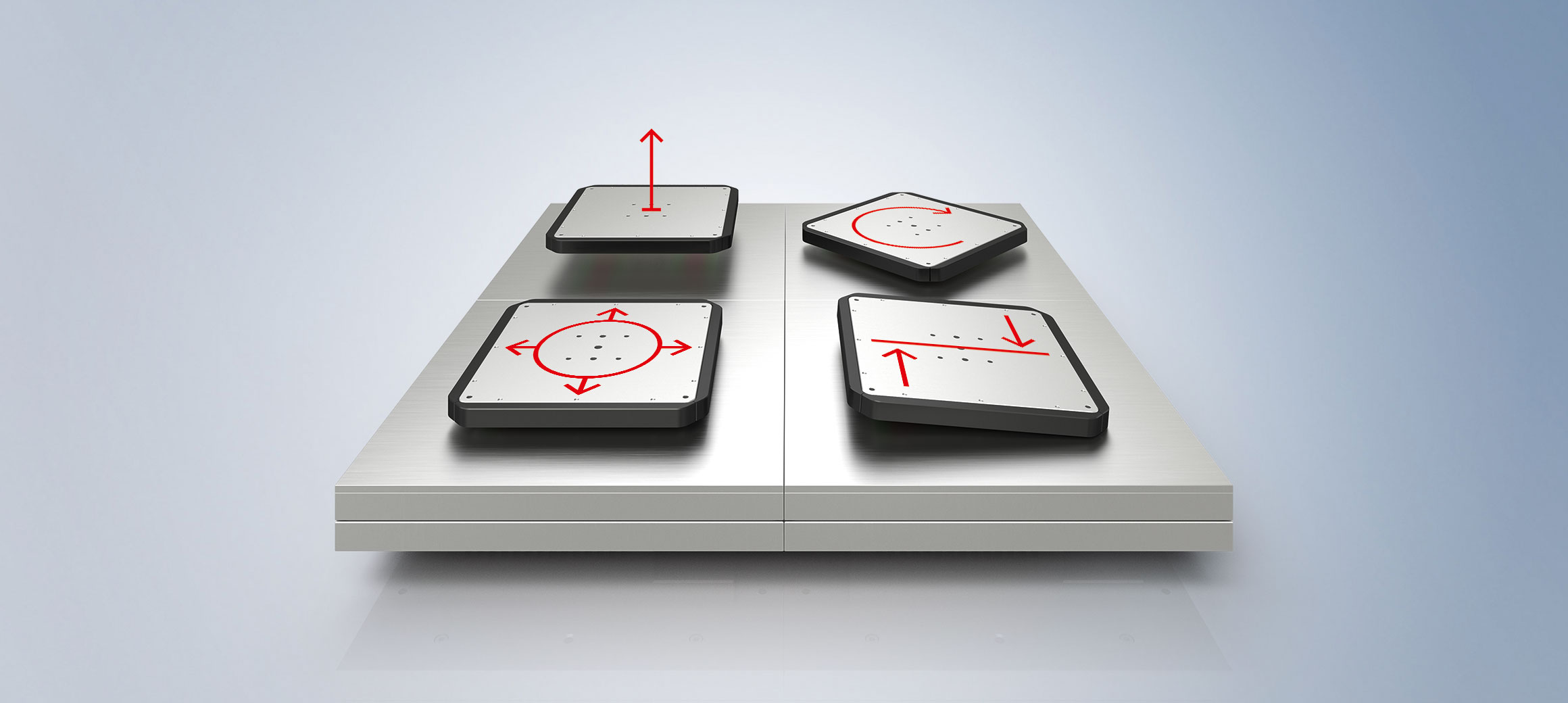

At the end of 2018, Beckhoff launched another disruptive innovation in the form of XPlanar, the planar motor system for levitating 2D product transport with up to six degrees of freedom. This technology enables completely new packaging machines to be developed and designed which have yet to be beaten in terms of flexibility and with which the manufacturing industry can save on packaging materials and raw materials.