Beckhoff helps Xiamen Jinghe Electric Automation develop fully automated N95 mask making machines

The global Covid-19 pandemic has created a huge demand for personal protective equipment (PPE), especially medical-grade facemasks. After returning to work after the Chinese Spring Festival holiday, Jinghe Electric established a team to design and produce facemask-manufacturing machines. To ensure high quality and hygienic mask production, the equipment developed by Jinghe Electric uses one-step forming technology to meet sanitary and technical specifications while reducing labor costs. In early May, Jinghe Electric started the design of N95 mask machine, using PC-based technologies from Beckhoff Automation. The design, installation and commissioning were completed in just two weeks, with the machines achieving production efficiency of 40-50 N95 masks per minute.

Xiamen Jinghe Electric Automation Co., Ltd. is a high-tech enterprise that specializes in R&D, design and manufacture of automated production lines, automation equipment for the electronics industry. It is the most important supplier of automation equipment for its sister company, Xiamen Hongfa Electroacoustic Co., Ltd. Over the past 10 years, Jinghe Electric has developed continuously and steadily, and now has a strong professional and technical team of more than 160 employees composed of senior engineers, technical engineers, professional technicians and others. Jinghe Electric keeps innovating and improving constantly, and has undertaken many key national technology projects. A number of R&D projects have won key new product invention patents and practical patents nationally. Jinghe Electric has also won many honors such as Xiamen High-tech Enterprises, Most Growing Enterprises, and the Science and Technology Progress Award.

The team of electrical engineers at Jinghe Electric started using TwinCAT 3 automation software from Beckhoff as a platform for developing automation equipment and production lines five years ago. The one-step N95 mask-making machines use a CX5130 Embedded PC along with EL1889 and EL2889 EtherCAT Terminals from Beckhoff. The machine’s motion control relies on the powerful TwinCAT Motion modules and real-time control of servomotors and stepper motors through the EtherCAT industrial Ethernet system. Distributed, IP67-rated EtherCAT Box modules further streamline I/O wiring. The entire program can easily increase or decrease equipment procedures in different production processes.

“Beckhoff products have proven to be extremely safe and reliable in our previous projects,” said Mr. Lei Ming, Chief Engineer – Electrical Department, Jinghe Electric. “We have also developed a number of in-house standardized application frameworks by using TwinCAT 3, and have gained significant experience in commissioning. The strong technical service and support from the Beckhoff office in Fujian has given us and our customers more confidence in choosing Beckhoff products.”

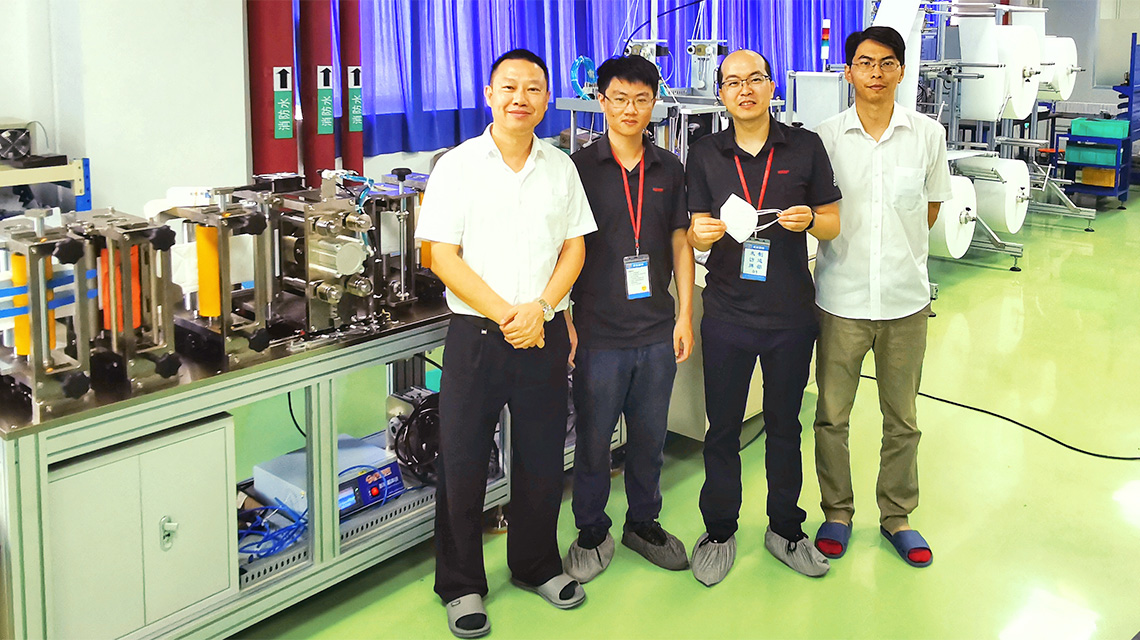

Considering the urgency of the equipment development, Cai Jianzhong, Technical Engineer at Beckhoff China, and Huang Huang, Engineer at Jinghe Electric, closely communicated about the equipment’s process requirements and laid out the program architecture. They used TwinCAT 3 Scope View to capture the motor speed position and the variable curve triggered by actions in the program, and to analyze the action timing and optimize the program to improve the production efficiency. It took only one day to complete the commissioning of this equipment.

“The use of the Beckhoff control system has enabled us to speed up the development and commissioning cycle of the N95 mask-making machine,” Huang explains. “EtherCAT fieldbus technology enables fast and accurate control of servomotors and stepper motors, and it solved the problems we had with communication interference and step loss in the previous pulse-control mode.”