Beckhoff Measurement Technology is used successfully in a wide range of industries and applications: whether in test benches in automotive production, for monitoring power and voltage values in power generation, or in research and science projects. Our numerous impressive references are a testament to the high performance and precision of our technology.

Current applications

EtherCAT measurement terminals in vehicle development at Mercedes-Benz

The chassis properties shape a vehicle’s character and ultimately also the identity of a brand. Mercedes-Benz leaves nothing to chance and checks the chassis properties on several test benches during development. Mercedes-Benz and system integrator DynoTec Prüfstandstechnik rely on EtherCAT, TwinCAT, and the ELM-series precision measurement terminals from Beckhoff for retrofitting.

Measuring forces at the detection limit with PC-based control

Calibrating multidimensional force sensors is considered the ultimate test of skill within measurement and testing technology. GTM Testing and Metrology GmbH in Bickenbach, Hesse, is taking multi-component calibration to the next level with a new approach. It is not just the measuring range, design, and size of the measuring equipment that are unique, but the automation concept as well: PC-based control, EtherCAT, and servo drive technology control and regulate the force application via a hexapod, while precision measurement terminals from the ELM series record all forces and torques in real time and with maximum accuracy.

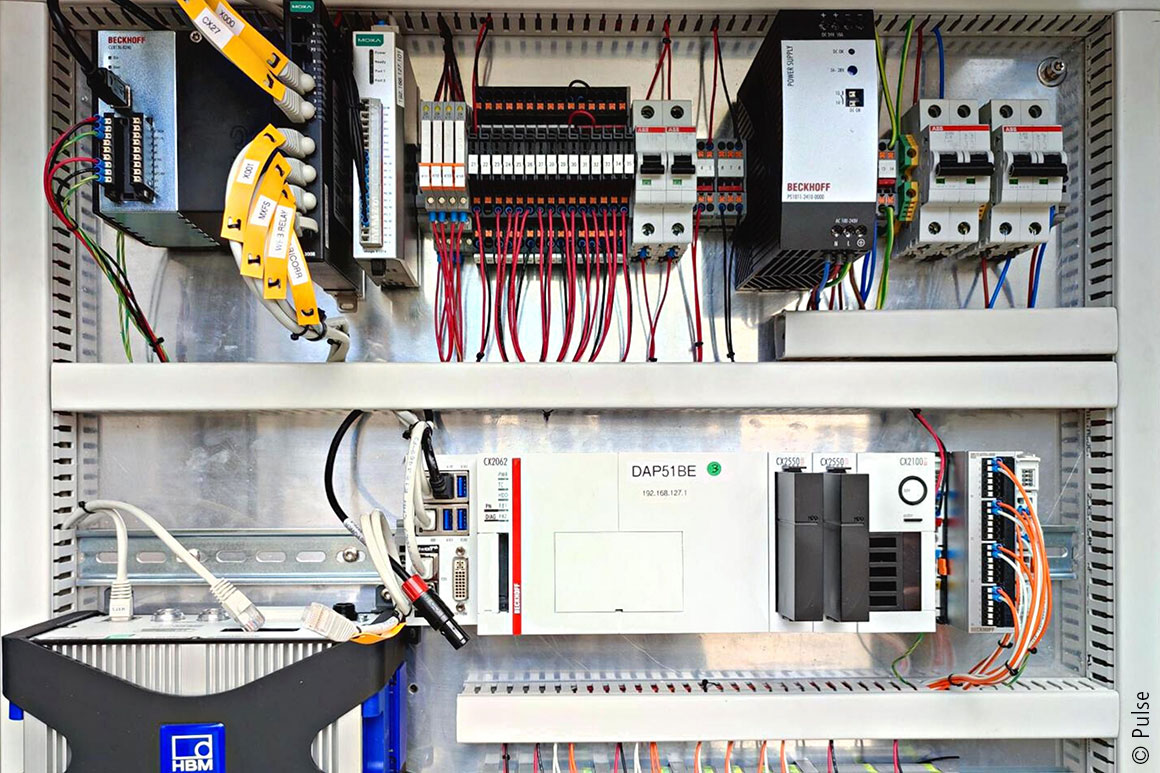

EtherCAT measurement terminals used to monitor wind farms

According to Pulse, the United Kingdom is the world leader in offshore wind energy and has more installed capacity than any other country. Nevertheless, the environmental conditions associated with wind farms such as these pose real challenges that require continuous monitoring of the entire system. Monitoring the wind turbine, rotor blades, and foundation in this way facilitates informed decisions regarding planned maintenance and structural inspections, which in turn mitigates the risk of unplanned shutdowns or expensive repairs in the event of a failure.

XPlanar in deep-learning-based optical component inspection in the automotive segment

Achieving the shortest possible inspection times – even when working with different components – is paramount when it comes to series production. This is precisely what Memmingen-based stoba Sondermaschinen GmbH set out to achieve with its InspectorONE optical inspection system, which is based on deep learning and features the Beckhoff XPlanar planar motor system at the conveyor system core. The system allows automotive suppliers to achieve extremely short cycle times of just 3 seconds when inspecting high-pressure injection valves, for example, and thus to inspect around 6 million parts per year in three-shift operation.