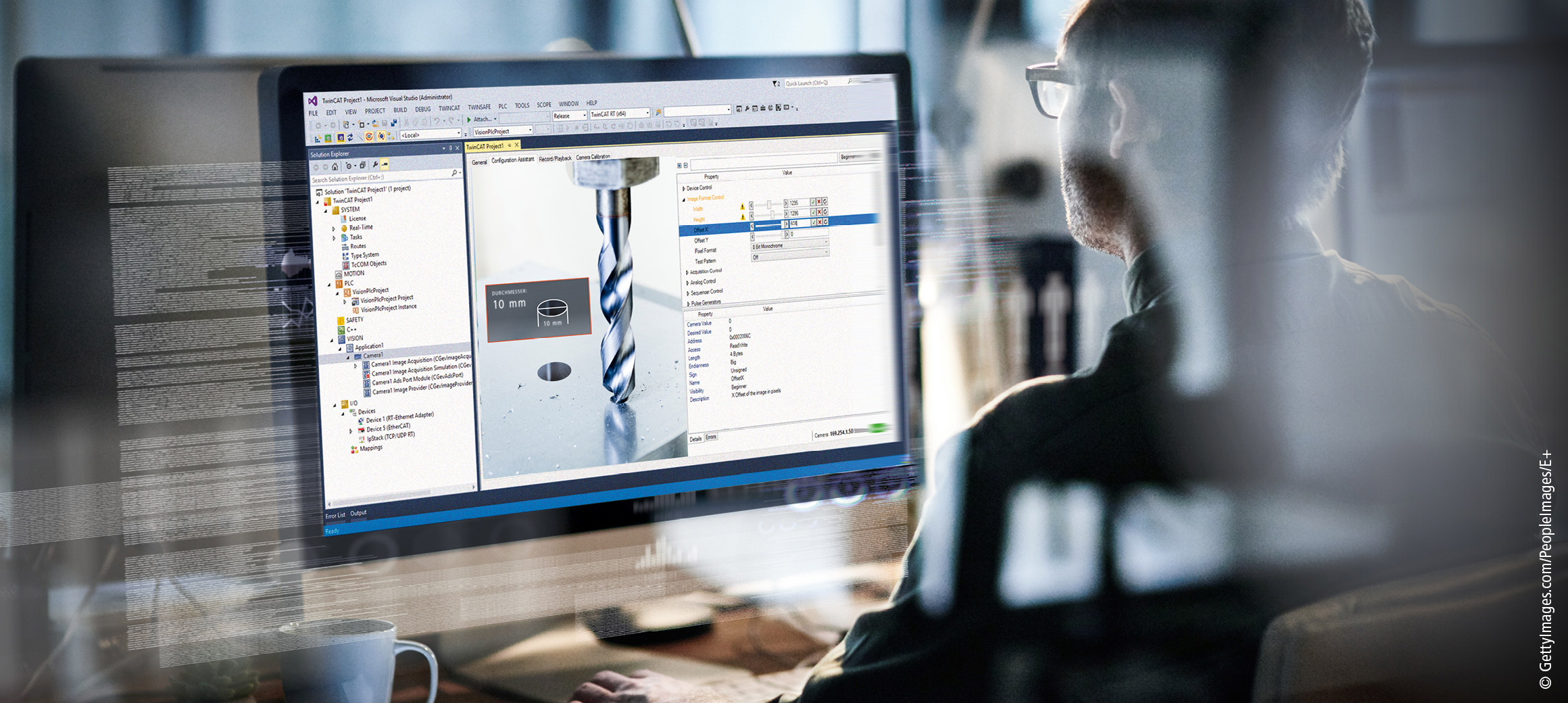

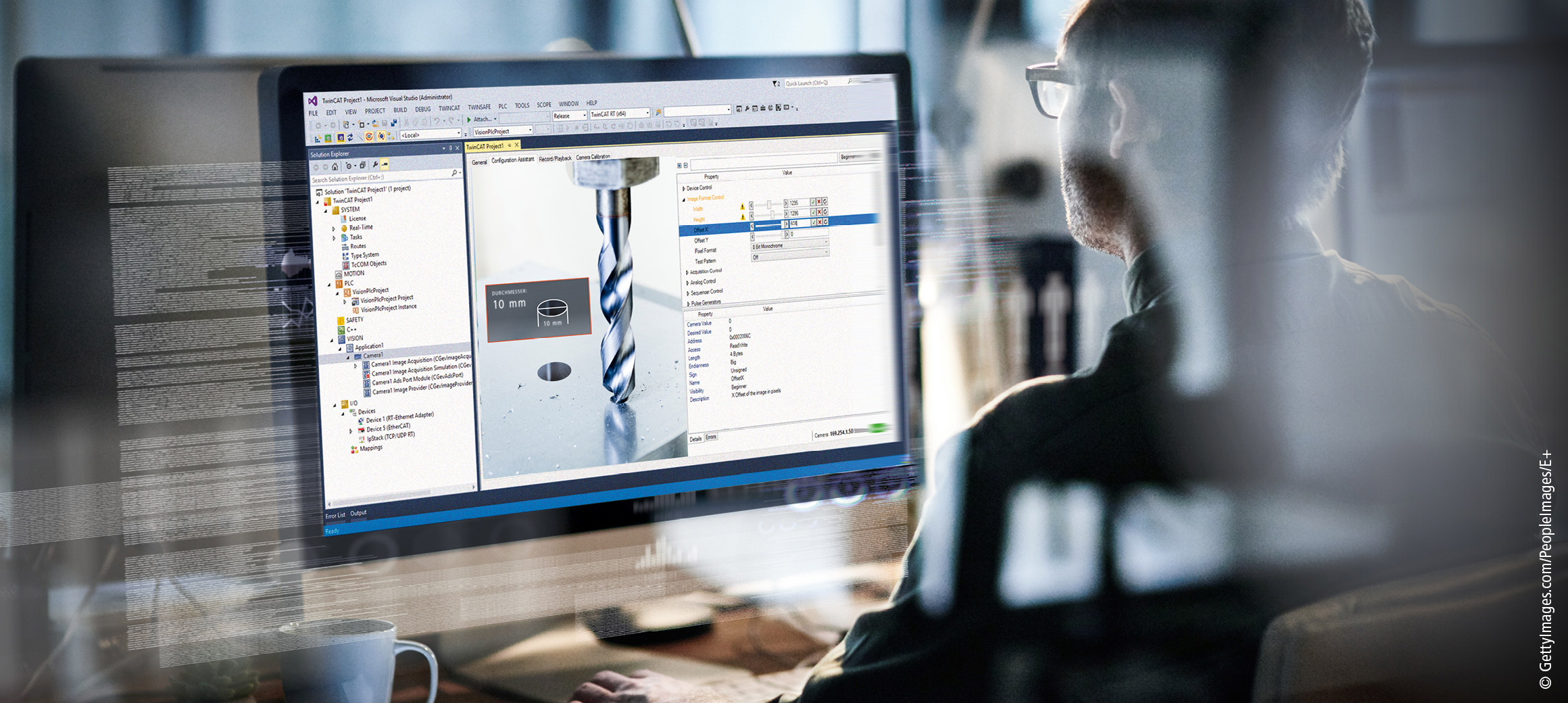

When people talk about motion control today, they naturally assume that it is a completely integrated solution. All aspects of configuration, programming and diagnostics for motion control must be fully integrated. Up until now, image processing has been different in that respect. It was characterized by special hardware, separate configurators for cameras, separate development environments and special programming languages, diagnostics that are completely decoupled from the PLC, and additional time delays due to the interfaces required by the separate systems. This entire landscape has changed with TwinCAT Vision. Image processing is now fully integrated into both engineering and runtime and can be configured and programmed in the same way as motion axes would be in the PLC environment.

Configuring cameras with TwinCAT Vision is as easy as configuring axes, i.e., all connected cameras can be found with one scan of the network. In addition, GigE vision cameras from many different manufacturers can always be configured in the same way with TwinCAT Engineering. Wizards make it easy to set up and calibrate a camera. All configuration data is stored in the TwinCAT project and is transferred to the camera when the PLC is started.

Efficient implementation without specialists

The complete image processing functionality is programmed in the PLC, from image acquisition to the finished evaluation. Alternatively, C++ and MATLAB®/Simulink® can be used. All algorithms – currently about 800 – are available as a library and are ready for use. This level of integration reduces training time, as the user does not have to learn a new programming language – which also reduces development costs. It makes image processing a normal part of the machine control application that can be programmed and maintained without specialists.

With the open control concept of TwinCAT, the user has the option of exporting the images via ADS and also full access to the raw image data right down to each pixel, which makes it easy to integrate user-specific extensions and image processing algorithms. Due to the execution of the image analysis in real time, the need for time-consuming communication from the PLC to a legacy image processing system and back is reduced. Everything runs in the same real-time environment, executed by the same tasks, which automatically guarantees synchronous processing, shorter response times and deterministic behavior. This is especially important for the combination of vision and motion control as well as for product tracking and ejection.

For parameterization and maintenance of the vision application, intermediate results can be displayed at any time in the engineering tool or in TwinCAT HMI. Alternatively, the images can also be saved in familiar image formats. A special feature is the combination of TwinCAT Vision and TwinCAT Scope. In this software oscilloscope, time sequences of variables can be combined together with the corresponding images from TwinCAT Vision directly in real time. This provides a camera view into the machine while simultaneously observing an associated analog or digital value, greatly simplifying machine diagnostics.

Open interfaces to third-party manufacturers have been supported by TwinCAT from the beginning. Now, this also applies to the connection of vision cameras. The international GigE Vision standard is supported where a certified real-time driver has been implemented. With this driver, numerous special cameras of different manufacturers and types can be integrated. In addition to line scan cameras, these include thermograph, polarization-sensitive and SWIR cameras. With an industrial Ethernet-based solution – such as GigE Vision – the Industrial and Embedded PCs from Beckhoff can be used for directly connecting one or more cameras. The Ethernet interfaces required for this are already available, supporting the usual transmission rates ranging from 1 Gbit/s to 2.5 Gbit/s and up to 10 Gbit/s. TwinCAT Vision can be used on almost all hardware platforms; in multi-core and many-core computers, all cores can be used for image processing. In addition to division into tasks and assignment to different cores, TwinCAT Vision offers the option of creating job tasks and assigning them to a vision job pool. The system can then automatically parallelize all functions suitable for these purposes.

The Beckhoff philosophy of computing as much as possible on one IPC therefore also works for image processing. One engineering environment for everything, full synchronicity, simple central diagnostics and a reduction in the number of components required are the advantages of the centralized control approach.

Wide range of applications

Industrial image processing – machine vision – includes applications from a wide range of industries. Typical tasks are object detection, position and orientation recognition, identification of 1D and 2D codes, the measurement of lengths, distances, diameters or angles as well as gripping point specifications for robots. The functions in the TwinCAT Vision library are specially optimized for these requirements and therefore meet the high industrial demands for robustness, reliability and stability. Beckhoff works continuously on further developments to constantly increase functionality and usability. For example, special Vision Controls were recently developed for TwinCAT HMI, which provide many functions in encapsulated form and can be easily configured saving the user time and allowing optimal integration of image processing tasks into the HMI. Another emerging trend accounted for is the increasing use of machine learning. TwinCAT Vision and TwinCAT Machine Learning will therefore be brought even closer together in the coming year as it will also be possible for Machine Learning to be used with image processing for the first time.