If the wind direction changes, the yaw system rotates the wind turbine rotor optimally into the wind. Apart from the electric drives, hydraulic brake systems are typically also used for this horizontal alignment and locking of the nacelle. However, the permanent use of the brake unit in the active wind tracking results in constant wear in the yaw system, leading to high maintenance expenditure. The use of the existing electric drive systems to develop the required counter-torque and to clamp the mechanism results in less wear and is more efficient.

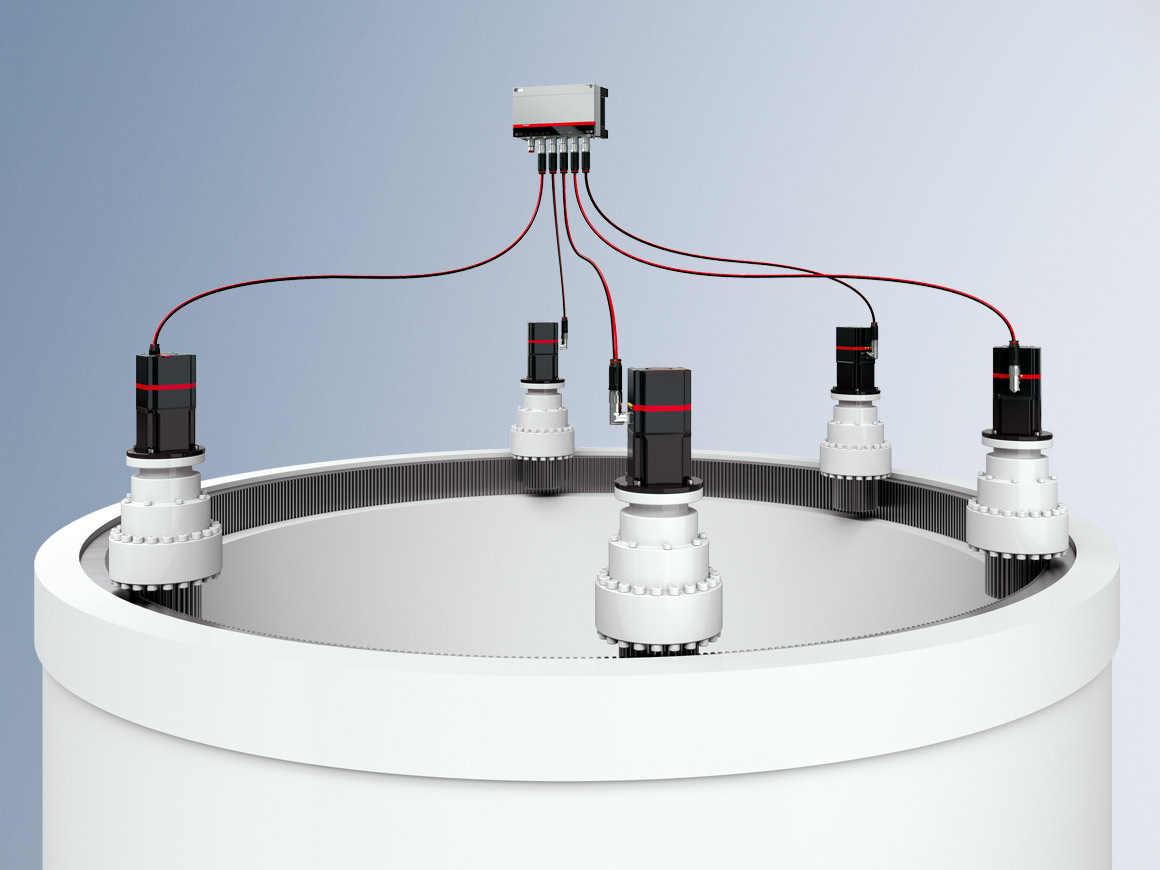

Traditional drive systems are often based on mains-operated asynchronous motors without soft start, as these are relatively inexpensive. To achieve a safe starting torque in soft supply networks despite that, the motor and the upstream power supply elements are often greatly oversized. However, modern wind turbines offer less and less space for control cabinets. Additional weight and volume must be avoided in particular in the nacelle. These requirements are fulfilled by the AMP8000 drive system with decentralized servo functionality integrated in the motor. Depending on the turbine size and load requirement, the quantity and output of the motors can be adapted for the reliable dimensioning of the drive and braking torques. In comparison with traditional solutions, the servo drive system based on the AMP modules from Beckhoff offers greater efficiency and the safety of adequate breakaway torques even in the case of grid fluctuations.

On account of the wear-prone braking systems, the wind tracking is operated only very sparsely in many turbines. With the new approach, in which the dynamic braking power is achieved without the assistance of the hydraulic brake system, a higher energy yield can be achieved at many wind farm locations through more dynamic wind tracking.

Your advantages at a glance:

- increased energy yield through more dynamic wind tracking

- cost reduction through lower maintenance requirement

- AMP modules reduce installation space and weight in the nacelle

- minimization of the cabling and assembly costs

- optional safety functions, e.g. for system maintenance

- integrated condition monitoring and remote diagnostics