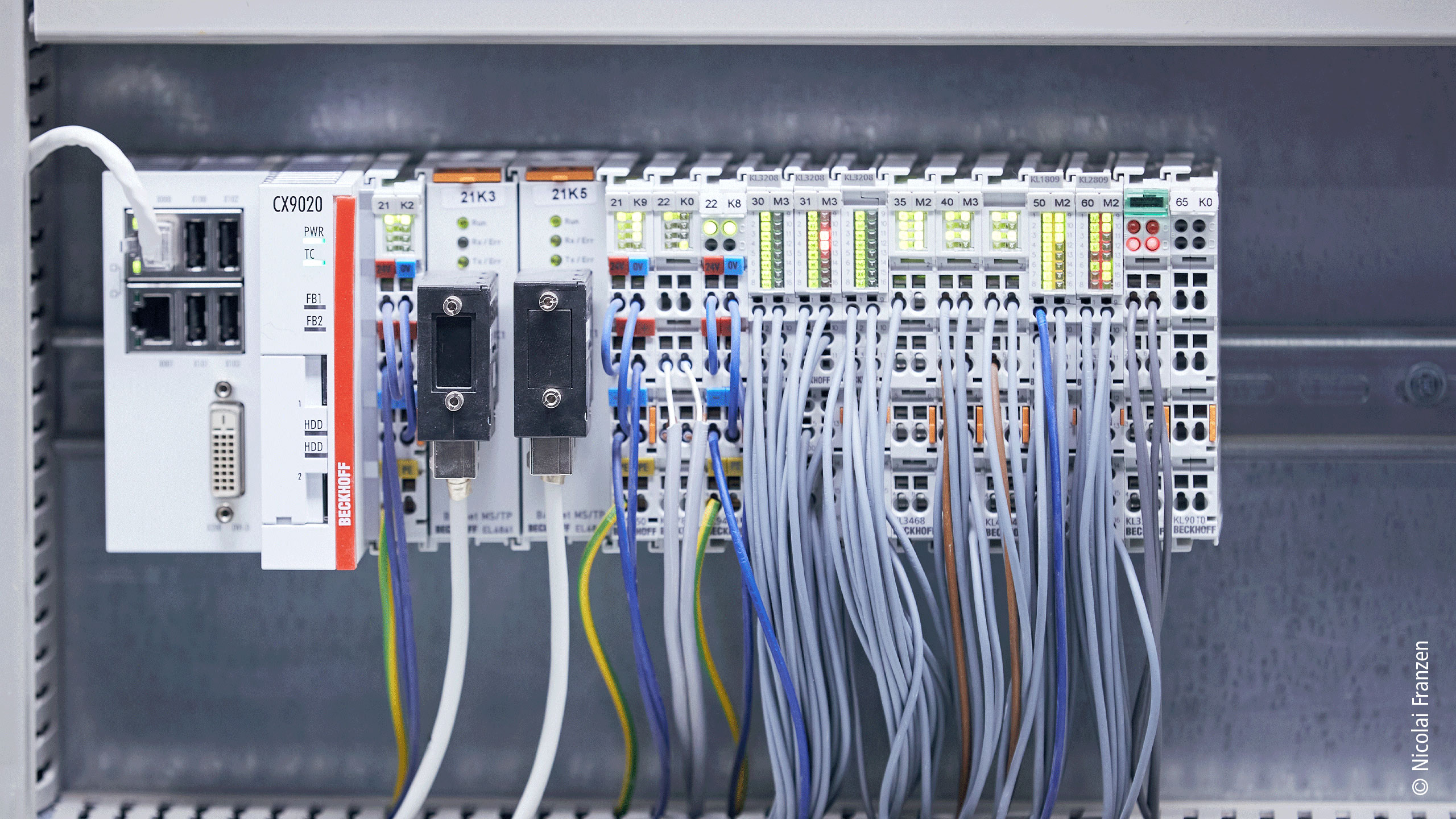

Embedded PCs used as BACnet controllers in building air conditioning system

Steigenberger Alsik Hotel & Spa in Sønderborg is not only the largest hotel in the Region of Southern Denmark, but also one of the most sustainable and climate-friendly hotels in Northern Europe. High-tech solutions ensure energy-efficient control of heating, ventilation and air conditioning (HVAC) systems, while offering guests the greatest possible comfort. The automation is a result of the ongoing collaboration between Beckhoff and Danfoss.

Alsik Hotel opened up in May 2019, adding a new attraction to the small town of Sønderborg and the Als region, which is rich in tradition. This is not only due to the public viewing platform on the 16th floor, from which visitors can enjoy a panoramic view of the former industrial harbor and the German-Danish border region on the Flensburg Fjord. The hotel's architecture, design and ambitions draw many guests and attendees of major conferences and events to the city. With 24,800 m2 of space and a height of 70 m, the 19-story building is a new landmark on the waterfront.

In the hotel's basement and on the 18th floor, HVAC systems combined with state-of-the-art building automation ensure comfortable temperatures and air conditioning in the public areas, a spa with a floor space of 4,500 m2 and the conference rooms.

Exceeding Danish energy efficiency building regulations

Alsik Hotel was financed by the Danish pension fund PFA together with the Bitten & Mads Clausen Foundation. Danfoss, the company behind this foundation and one of the leading manufacturers of components for HVAC, equipped the hotel accordingly. A wide range of I/O components from Beckhoff, including 1,170 analog and 712 digital I/Os as well as 43 BACnet MS/TP EL6861 EtherCAT Terminals and 7 M-Bus KL6781 Bus Terminals, are used to network the Danfoss solutions. In addition, a total of 48 Embedded PCs from the CX8091, CX9020 and CX5020 series in the large, scalable Beckhoff product portfolio are used as BACnet-compliant floor or equipment controllers. They provide the PLC functions for the building climate control and integrate them with the hotel's building management and booking system.

According to the Danish building regulations (BEK2020), which is two levels higher than the requirements to the hotel at design freeze in 2015, buildings may consume a maximum of 25 kWh/m² of energy, which is equivalent to a CO2 neutrality of 75%. Hotel Alsik is designed to even slightly exceed these specifications with a CO2 neutrality of close to 76%. The energy frame for the hotel is designed to be 4 times better than the requirements to the hotel at design freeze in 2015.

"Our vision from the beginning was to create a state-of-the-art hotel with the highest possible level of automation to achieve maximum comfort for our guests. In addition, we wanted to achieve the highest possible energy efficiency and a CO2 neutrality of 76%. We want to be one of the most sustainable and CO2-neutral hotels in Northern Europe at all times," says Michael Kurth, facility manager at Alsik Hotel.

Booking system communicates with the rooms

As a special feature, the hotel's booking system is connected to the HVAC system control via an IBI (Intelligent Building Infrastructure) solution. As soon as guests check in at the front desk, the temperature in their room adjusts automatically and the ventilation system turns on. However, guests can also regulate the air in the room if they wish. When they check out, all functions are automatically switched off again. "We don't just keep the heating and ventilation systems running when a room is vacant. That would be a waste of energy," says Michael Kurth.

Energy efficiency is also being optimized in other ways. For example, shower heads and faucets are equipped with water savers. Waste heat from all areas, including the large wellness area, is reused. Sensors inside and outside the building take all relevant measurements in real time, and the data is collected and processed to ensure the most efficient building operation possible.

Open standards are crucial

Close cooperation between Danfoss and Beckhoff since 2017 paved the way for Beckhoff as a supplier in these kinds of building automation applications. For Hotel Alsik, automation solutions were needed that would be freely programmable and would work smoothly with Danfoss components, including valves, ventilation units (AHU, Air Handling Units), frequency converters, measuring devices and wireless components.

"The open standards supported by Beckhoff allow us to reach our goals and create solutions tailored to our requirements. In addition, Beckhoff has already developed a software function block for the NovoCon digital valve from Danfoss, which can be used to collect a wide range of data. This makes it easier for us to configure the controller. Beckhoff has also developed special programs and protocols for controlling our wireless components. The close cooperation since 2017 has strengthened our choice of Beckhoff as a supplier for Hotel Alsik. We know the stability of their solutions and the innovative power of their employees," Michael Kurth concludes.