Interview on PC-based control technology in the entertainment industry

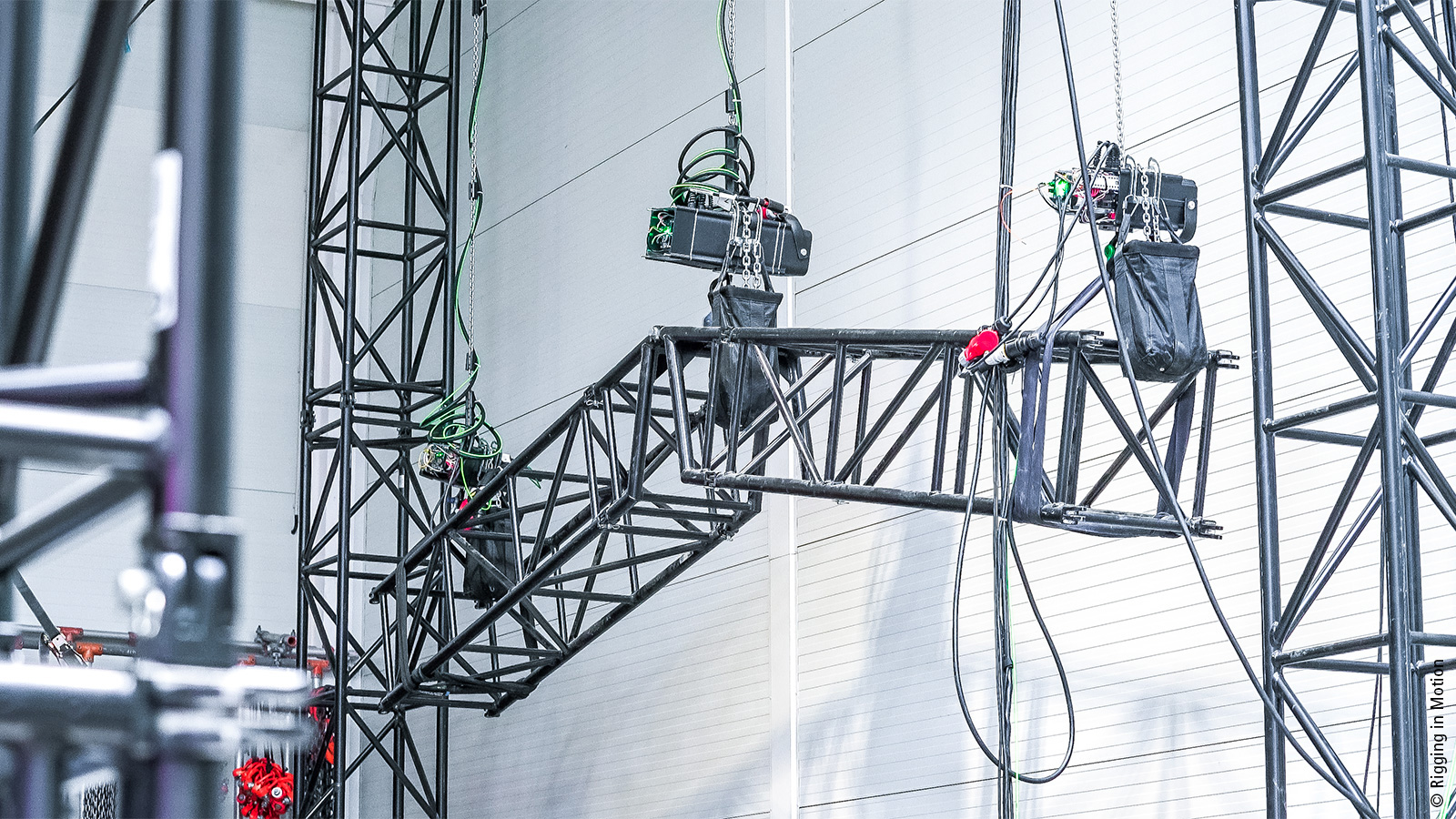

With its headquarters in the Hungarian city of Dunakeszi, Rigging in Motion Ltd specializes in the automation of stage technology. The company’s trusses and rigging platforms are used worldwide in film productions and event stunts – all automated with PC-based control. The editors of the CNCMedia trade portal spoke to György Posztós, Managing Director of Rigging in Motion Ltd, and Project Engineer András Till about Beckhoff technology as a driving force behind spectacular scenes and stage shows.

Mr. Posztós, how long have you been involved in stage automation and what prompted you to start developing your own solutions?

György Posztós: I have been in the business for 40 years now. I set up Rigging in Motion in 2013 with the aim of automating stage technology, since we couldn’t find anything anywhere in the world that was capable of bringing customer inquiries and our ideas to life. We knew what we wanted to do, but we lacked the right tools to make it happen.

How did you become aware of Beckhoff solutions and PC-based control?

György Posztós: I travel to exhibitions for stage technology every year, and when I came across the Beckhoff booth at Prolight + Sound in Frankfurt around five years ago, I was fascinated to find that they were offering components rather than finished solutions, which was perfect for us since we were looking for tools and building blocks to develop our own products. After the exhibition, Beckhoff Hungary contacted us and offered us some products to try out. It didn’t take long for us to see that this was going to be a good fit, and so we have been using Beckhoff technology regularly for various productions ever since.

What has your experience been like in practice?

György Posztós: We haven’t had a single problem so far and we have already been able to bring several major films to life with the help of Beckhoff technology, including Robin Hood, Terminator, Dune and Gemini Man – often under difficult climatic conditions. Perhaps the most challenging of these was a scene in Terminator, where an all-terrain vehicle is dropped from a plane while being rigged for a parachute drop. We had to move the heavy SUV with three protagonists on board at a height of 30 meters in order to simulate the parachute drop and the swinging action with our trusses. We quite literally had the lives of three people in our hands!

What direction are you heading in with future developments?

György Posztós: Well, up to now, we can only fly objects and people within a limited range, so we have to bear these limitations in mind when taking on the challenges that a director or cinematographer may come up with.

Mr. Till, how would you describe your day-to-day work?

András Till: The work we do really does vary, covering everything from the development and production side through to the execution of the actual film scenes or events. The productions don’t come to our premises; we go out to the filming or event location and set up all the technology right there on site, from the loading ramp to the control system and aluminum structures. Directors often have very specific ideas for which there is no ready-made tool. In cases like these, we build the mechanics and figure out how to automate and monitor them in the safest possible way. Sometimes it’s as simple as raising flags on two ropes, other times we have people flying through the air. Once we even had a singer land on the jury’s table on a Hungarian TV show. These examples just about demonstrate the range of possibilities when it comes to what our control system has to be able to handle.

And how is this control system structured?

András Till: The Beckhoff CX9020 runs TwinCAT 3 with a number of software extensions. Alongside some of the Beckhoff add-ons, we have also written some ourselves and integrated these into the system. Our performance requirements are already met perfectly by one of the smaller Embedded PCs from Beckhoff. We can control up to 24 axes via the CX9020, and it also works without fail with 32 axes if required; however, the transport box would have been too large in this case and less straightforward to handle on set. The system is modular and the components can work independently of each other. Any additional accessories we connect are automatically detected, which makes our work so much easier on site.

What has been your experience in terms of the reliability of the system?

András Till: We have been transporting our control equipment by truck from one set to another for years without any sign of a defect, whether electronic or mechanical. There was one time where an I/O card hadn’t been connected properly: the operator error caused a short circuit on the card, the system itself, however, didn’t fail. The Beckhoff technology works flawlessly.

How does your system differ from others?

András Till: Our solution really is unique – and the special thing about this intelligent system is that it works with relatively inexpensive motors. It adds a little control intelligence, which means we can use it to achieve things that were simply not possible before. This could be anything from an additional synchronized movement during a show to a quick move of a back wall to open up the backstage area. With conventional motor control systems, the motors have to be synchronized individually in a time-consuming process, whereas ours handles all of this at the push of a button to save a great deal of time during both installation and use.

What has the customer feedback been like?

András Till: When we first presented our development, the initial reaction was, “Why are you putting so much software and electronics into it? It’s going to be expensive!” But from the moment the organizers and production companies saw the intelligent functions such as the position and weight feedback and the safety systems in action, everyone began to realize just how much potential there was.

This interview was conducted by the editorial staff of CNCMedia, www.cnc.hu