Interview with Hans Beckhoff on innovations and future prospects

Source: A&D 11/2021, Germany, www.industr.com, publish-industry Verlag

The interview was conducted by: Christian Vilsbeck, A&D

Hardware is becoming more and more interchangeable, so software will be the only way to generate added value in future. In an interview with A&D, Hans Beckhoff refutes this theory as he believes that hardware will still play a central role in years to come. It will just be combined with increasingly complex software. The owner and Managing Director of Beckhoff predicts a bright future for the automation industry if technology and innovations continue to be the focus.

In 2020, Beckhoff achieved a two percent increase in sales with €923 million – despite the coronavirus crisis. Which factors helped with this performance?

Hans Beckhoff: From our perspective, the actual sales crisis in the automation industry started back in mid-2018 as the series machine manufacturers in particular recorded a drop in sales, which – of course – also impacted automation manufacturers. The coronavirus pandemic somewhat delayed the recovery process from this. Beckhoff, however, has seen decades of healthy fundamental growth since the company was founded. Since 2000, we have enjoyed an annual growth rate of around 14 percent. The basic growth has still been continuing during the crisis and is helping to compensate for the drop in sales caused by negative developments with our established customers. What’s more, the Asian market recovered much quicker than expected and we have seen strong rates of growth there. This made up for losses in other areas.

And what do you think of the idea of reshoring during times of the pandemic and business uncertainty? Do you think this has confirmed your strategy of local production in Germany?

Hans Beckhoff: When it comes to Europe and the USA, yes – with China, no. With our three large central warehouses in Germany, Minneapolis and Shanghai, we are currently well and reliably positioned to attend to our customers. However, the Chinese market is growing tremendously and accounts for more than 20 % of our global sales. We have therefore decided to build a production facility to support our Chinese business in China. So you could say we are onshoring rather than reshoring. It goes without saying that the political and customs-related framework conditions have also played a role in this decision. Unfortunately, there is still not an equal playing field between China and the EU as demanded by European and German politics and which we believe would be appropriate and fair.

What is absolutely essential for medium-sized enterprises to stay competitive, particularly in times of crisis? How would you rank technology, partnerships, and internationalization in terms of importance?

Hans Beckhoff: We are a technology-driven company – that’s our DNA, which is why sustainable technologies will always be our number one priority. That’s how we get and keep our customers. Think about it: In the automation sector, customers rely on having a manufacturer who supplies important technological innovations and new ideas now and will continue to do so in the future. Therefore, it is the responsibility of technology-driven companies to not just listen to their customers carefully to learn their needs but also surprise them with new ideas. We have a huge range of technologies available and can therefore give our customers an edge. Lots of medium-sized companies are technological leaders in their field but, due to their level of specialization, they are faced with a challenge when it comes to positioning themselves on an international level to achieve scaling effects in production and with costs. However, companies also need to help each other out with partnerships. These should generally not be in your core area of business as this is where you need your own new ideas and solutions. Nevertheless, product segments are increasingly merging – sensor technology and communication, for example. Here, there are key areas that other companies are better at. You should therefore get this expertise through partnerships. Something that is a sideline technology for one company is another’s core technology and vice versa.

You have mentioned innovations and core technologies. Original employees with crazy ideas, who often mess about a bit, often drive innovations. Do you promote courage and are you prepared to take risks, or even suffer setbacks?

Hans Beckhoff: You should never suppress your team’s creativity – for a technology-driven company, that would be their downfall. Everyone is allowed to mess about at our company – in fact, this is vital to new innovations. We also do this a lot in meetings. We usually spend the first few minutes on completely stupid stuff, which ensures that all ideas are discussed in a democratic manner. However, it is also important for there to be a central body in the company, which is ultimately responsible for deciding the technological direction and implementing this. Without a central, strong hand, a technology company can lose its way.

Despite good technology, lots of manufacturers seem to think that their hardware is becoming a commodity as the value creation is increasingly in the software. With solutions like XPlanar and XTS, you are consistently proving the opposite. In the future, will those who can offer a smart combination of both be viable?

Hans Beckhoff: First of all, I believe that the automation industry has a bright, secure future ahead. This market is growing roughly proportionally to the global gross domestic product year on year. The end products that are made always need to be more and more precise, sophisticated, and affordable. The tolerances are becoming ever tighter to achieve better functionality and reduce material use. That can only happen with automation. Automation and new machines are the only way to meet the ecological requirements for production to be energy efficient and preserve resources. Automation technology is essential to achieve the required level of functionality. The two main growth drivers are the increasing global population and rising prosperity. However, the ecological aspect is also driving growth, which is why all production facilities in the western world are gradually being updated. With the exception of a couple of cyclical economic crises, which are to be expected, the next ten to twenty years are looking remarkably secure. Hardware will always play a key and central role. Machines are made up of hardware. The only way to increase capacity is with hardware. Hardware is just being combined with increasingly complex software. However, I believe that the transition to purely software-based services and the revenues derived from this will take even longer as we need hardware – it’s as simple as that.

A combination of hardware and software is surely also edge computing. Do you smile to yourself when your competitors hype up this technology everywhere? Have you not been doing this from the outset in principle?

Hans Beckhoff: You are absolutely right as edge computing is integral here! In 1986, we launched our first PC-based controller – and since then, we have combined the latest IT, communication, and automation technology. Our Industrial PCs collect data, trigger functions, and boast a level of intelligence that every machine builder can access with ease. All that, which we now call edge computing, comes naturally to us because PCs have always been at the heart of what we do. Features such as diagnostics and remote maintenance come as standard with us. At the beginning, I just couldn’t understand what was so special about edge computing... so yes, I had to smile.

Beckhoff has now been providing Industrial PCs for 35 years. Are there any milestones from this period that stand out to you?

Hans Beckhoff: There are loads I could tell you about! For example, in 1986, we installed the first PC with integrated color screen in a 19" housing. The commercial constructions at the time were not particularly well suited to industrial use, which is why we also started to develop our first in-house motherboard in 1989. With this, we then launched the first compact Industrial PC with LCD screen in 1990 with the C2000. To this day, we still develop and produce all of our motherboards ourselves to achieve the required quality, construction, and long-term availability for industrial use. Control Panels have also become a standard for many years now. They are now a global success and we were the first to make them back in 1998. You basically take a block of aluminum and build an LCD screen into it. Ten years later, Apple did the same thing with smartphones [*laughs*]. This means that we can build attractive, robust Control Panels and can easily create customer variants as we mill everything from scratch.

So can I use the quote “Apple was inspired by Beckhoff”?

Hans Beckhoff: That would be stretching it a bit [*laughs*]. But when clever people put a lot of thought into an almost identical task, they will come up with very similar results. Another milestone was then in 2002, when we launched the CX1000, one of the first DIN-rail PCs on the market – there had been nothing quite like it beforehand. Now, more than half of our PCs are sold as the CX series in the DIN-rail format. We also committed to the manycore architecture very early on. That is not one of our achievements, but we use the benefits to implement control processes that run in parallel on the machine. This means that we can guarantee real-time processing and implement data analytics, image processing, or voice commands simultaneously.

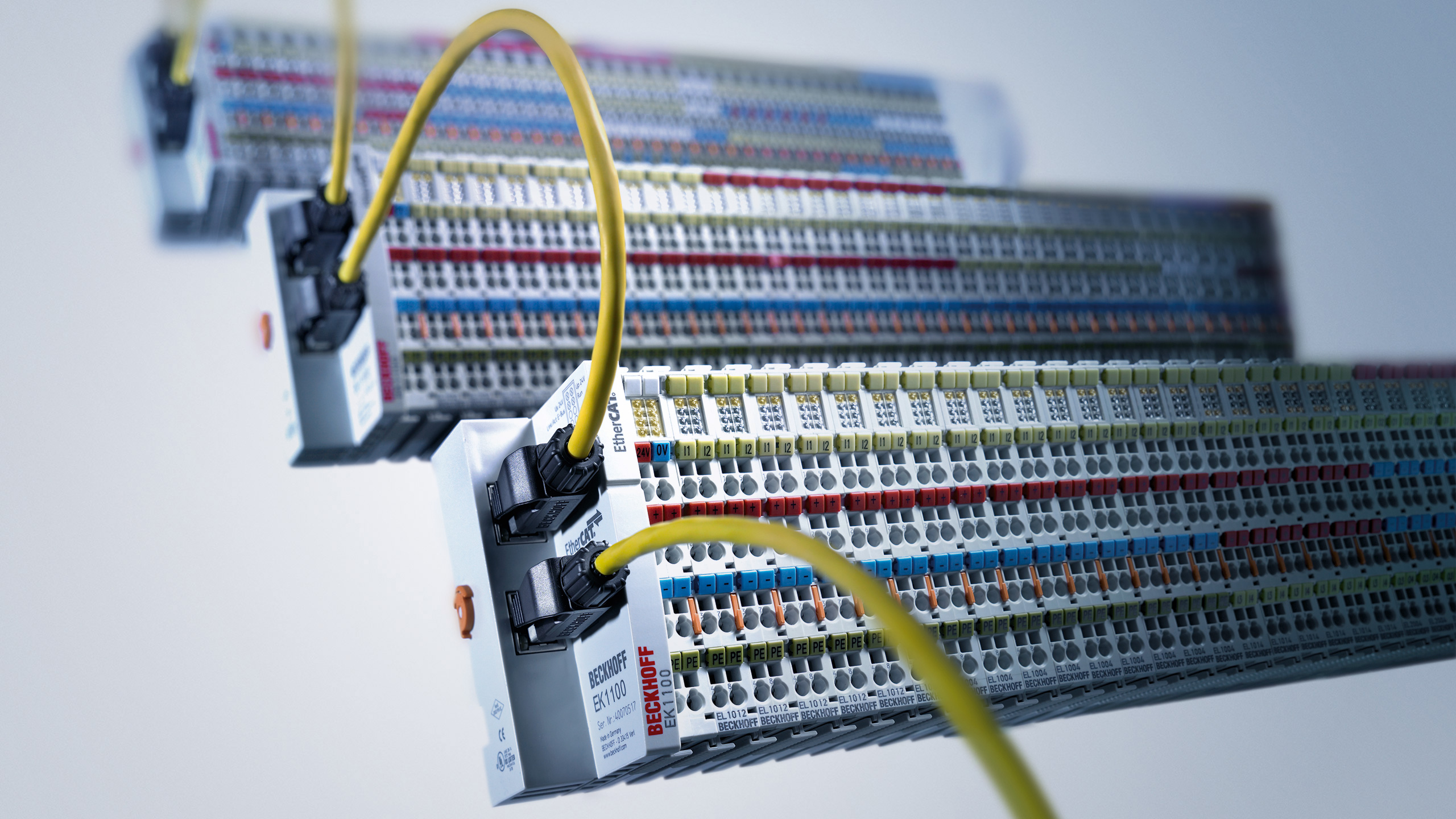

Nevertheless, PC-based control technology is not all Beckhoff has to offer. For example, with electronic terminal blocks, you established a global standard 26 years ago. Your extensive I/O range is still based on the original concept. Now, you are a person driven by innovation – do your terminal blocks not drive you a bit mad?

Hans Beckhoff: No, on the contrary, they make me really proud! The terminals that we launched 26 years ago are still available as a standard part of our range. We have discontinued virtually nothing in this area. By the way, we also haven’t really raised any of the prices over this period. The terminals are a success story as the chosen construction and electronic concept fit so perfectly that there hasn’t been any need for any major changes to date. When we announced the terminals at the time, we wholeheartedly believed that we had created a new building block for automation technology. And we proved to be right as it’s not just us – practically all our competitors also offer similar products. We didn’t file a patent for the electronic terminal blocks at the time and with hindsight, that was not a particularly smart move, but we were still a relatively small and inexperienced company back then.

In contrast to terminal blocks, we have artificial intelligence. Does a company need to understand the possibilities of AI first of all to be able to use it to add value and generate innovations in future?

Hans Beckhoff: It is always useful to understand the core principles of a technology – particularly if you want to sell solutions based on it. We just can’t imagine it any other way at Beckhoff as technology is in our blood. At Beckhoff, there are lots of groups with between three and ten engineers each. Each group has its own field of expertise, such as OPC UA, robot kinematics, EtherCAT, and – of course – artificial intelligence. A real-time inference machine has now been developed here, so a runtime embedded in the PLC for AI algorithms. With this, our customers can incorporate AI into their machine controller by simply activating a software module. But as you asked, you need to understand data, that machine learning is just mathematics, and know how “training” your AI actually works. Then, and only then, can you improve your own products in a meaningful way with AI integration and provide added value for your customers. AI helps, for example, with our XPlanar transport solution with floating movers so that these can find the optimum routes independently – self-optimization in other words.

Talking of XPlanar, does it annoy you or do you feel honored when competitors launch solutions that are reminiscent of Beckhoff innovations?

Hans Beckhoff: Good ideas get copied and it is, of course, an honor and confirmation that we have done something right and others are lagging behind. And if competitors offer similar solutions as a result, then it will make competition stiffer and also help to make these new technologies more well known and accepted. XPlanar is a fascinating technology: floating, contactless, zero-wear, quick, hygienic, intelligent transport systems – yet another building block of automation that could develop into a global standard.

Your portfolio of solutions is becoming more and more complete. Do you want to become a complete automator and one-stop shop for your customers?

Hans Beckhoff: We are both! If you want to supply products globally, you need to be the best in your class. At the same time, you also need to be open in order to harmonize with your competitors’ products. That’s what many customers appreciate with us. It goes without saying that there are different types of customer: Some want complete architecture from a single source, others see themselves as the system integrator and need the freedom and tools to integrate as independently as possible. We love working with both.

And why should machine builders choose Beckhoff as a solutions partner?

Hans Beckhoff: Because we offer the best technology for machine builders to achieve a competitive edge with their applications. And with Beckhoff, they have an innovative, rather revolutionarily minded supplier at their disposal, who will drive them throughout with new ideas. So they can be sure that they are not relying on a supplier that is always somewhat lagging behind on the market. We also advocate trust. Beckhoff guarantees performance, quality, value for money, innovation, and reliability. That’s exactly why we have countless customers who have been working together with us for years and years.

It’s now time for the last question. What goals have you personally set for Beckhoff for the next few years?

Hans Beckhoff: More technical revolutions of course! It’s my hobby and has kept me young for 40 years in my company. So I am always involved in our innovations, whether that’s in an advisory capacity, giving feedback, or providing motivation. What’s more, it also brings me a great deal of joy keeping my company on track for growth. I am responsible for ensuring this for our customers, employees, and the global Beckhoff community. None of our employees should be worrying about this. There is also the huge task of handing my company over to the next generation. That’s my children Frederike and Johannes, both of whom have worked at the company for a few years and have been doing a great job. In addition to them, we have lots of other talented individuals at Beckhoff. A company of this size can no longer be managed by family alone. We will need a fresh management team here in future. The team who developed the company with me is a great deal younger than me but still not “really young”. We therefore need to transition to the next generation within the next five to ten years. And our guiding principle will always apply: “Engineers must save the world!” Our company plays a role in this, as do I.