PC-based control technology from Beckhoff has been around since 1986 – in other words, for 35 years now – and the TwinCAT automation suite since 1996 – a quarter of a century already. Tellingly, TwinCAT is short for The Windows Control and Automation Technology. The user benefits not only from the high functionality of the software, but in particular from its modular expandability extending to support for innovation factors such as machine vision and artificial intelligence.

In 1996, the first software generation TwinCAT 2 was introduced. This version is still available and continues to be maintained, which is proof of continuity and compatibility. Windows served as the operating system and the PLC programming was adapted to meet the requirements of the IEC 61131-3 standard. It was now possible to implement a control system on a “regular” PC with a standard operating system. Another milestone was the decision to align the TwinCAT programming environment with the predominant IT programming environment. Microsoft Visual Studio® is used for all major IT software developments, and Beckhoff also used this tool to develop TwinCAT 2 software. So why not develop PLC software applications with Visual Studio® as well? The corresponding TwinCAT 3 software generation was introduced in 2010 and delivered to customers from 2011 on – which makes for another 10-year anniversary and another track record.

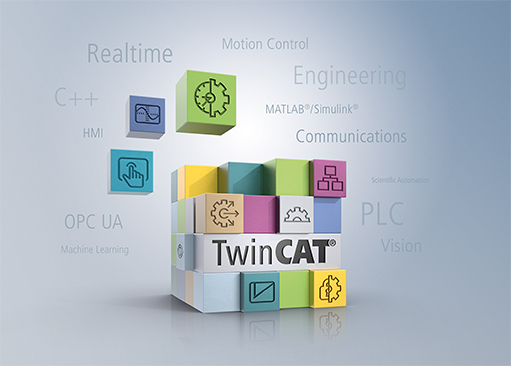

The integration of the TwinCAT tools into Visual Studio® created a completely new engineering environment. With additional “programming languages” such as C/C++ and MATLAB®/Simulink® becoming available, further possibilities opened up to more efficiently generate code for machines and systems. This was again a bold and correct corporate decision. In addition to programming, TwinCAT offers an I/O configuration interface for different fieldbus systems – first and foremost EtherCAT. Motion control applications from simple PTP movements to sophisticated CNC and robotics are just as much part of the ongoing evolution as safety functions, image processing for machine vision and machine learning. With the advent of Industrie 4.0 and the Internet of Things (IoT), it quickly became clear that the cloud, long established in IT, would also become important in the automation market. Beckhoff therefore already presented solutions for IoT and cloud connectivity in 2015.

Products

Neil Pearce

Beckhoff Automation Limited

Unit F3, 4 Orbit Drive

Albany

Auckland 0632

New Zealand