Labeling and grouping unit in a packaging line for toothbrushes

Koch Pac-Systeme, Germany

Headquarters South Africa

Beckhoff Automation (Pty) Ltd

Koch Pac-Systeme, Germany

Companies in the printing industry face challenging conditions, with customers requiring the highest print quality, customizability, short production times, and small batch sizes. This makes it all the more important to have intelligently automated, highly flexible systems for digital, 3D, and packaging printing. As a printing press manufacturer, you can develop these systems efficiently and scalably with the help of PC- and EtherCAT-based control technology from Beckhoff. We also offer a central software platform for engineering, runtime, and diagnostics in the form of TwinCAT, which will allow you to implement all processes and functions in a seamlessly networked and future-proof manner.

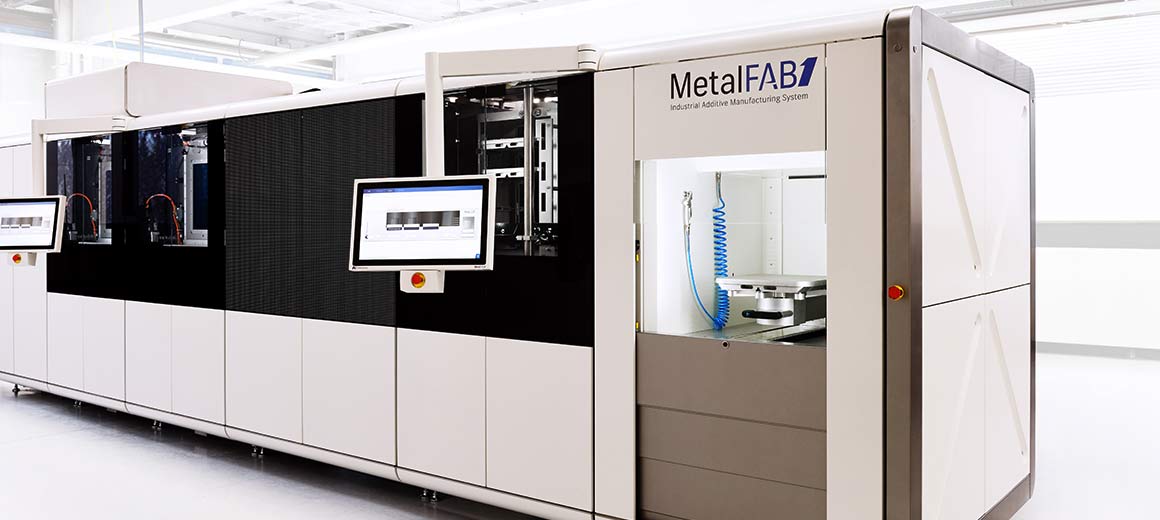

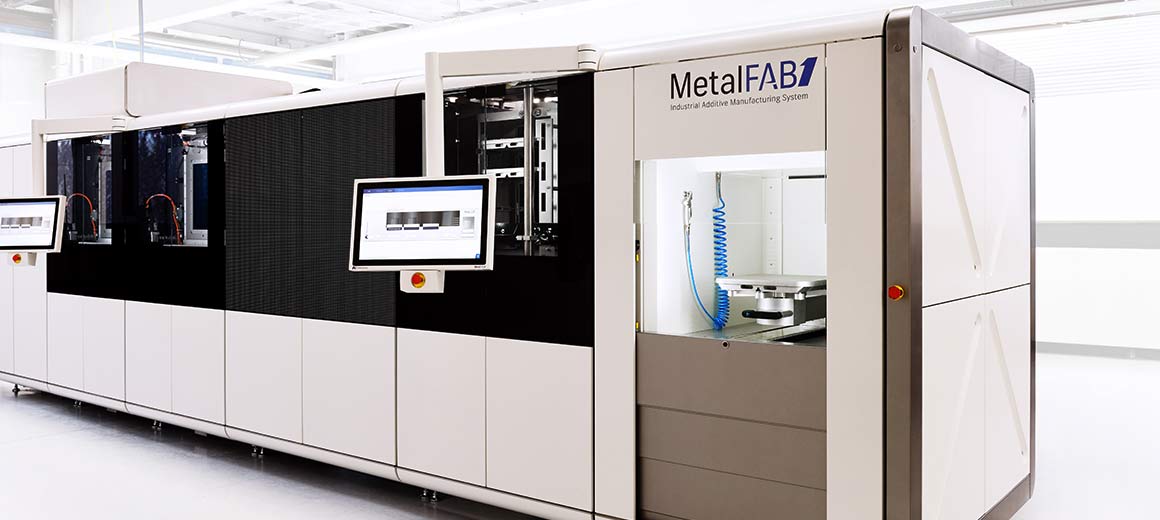

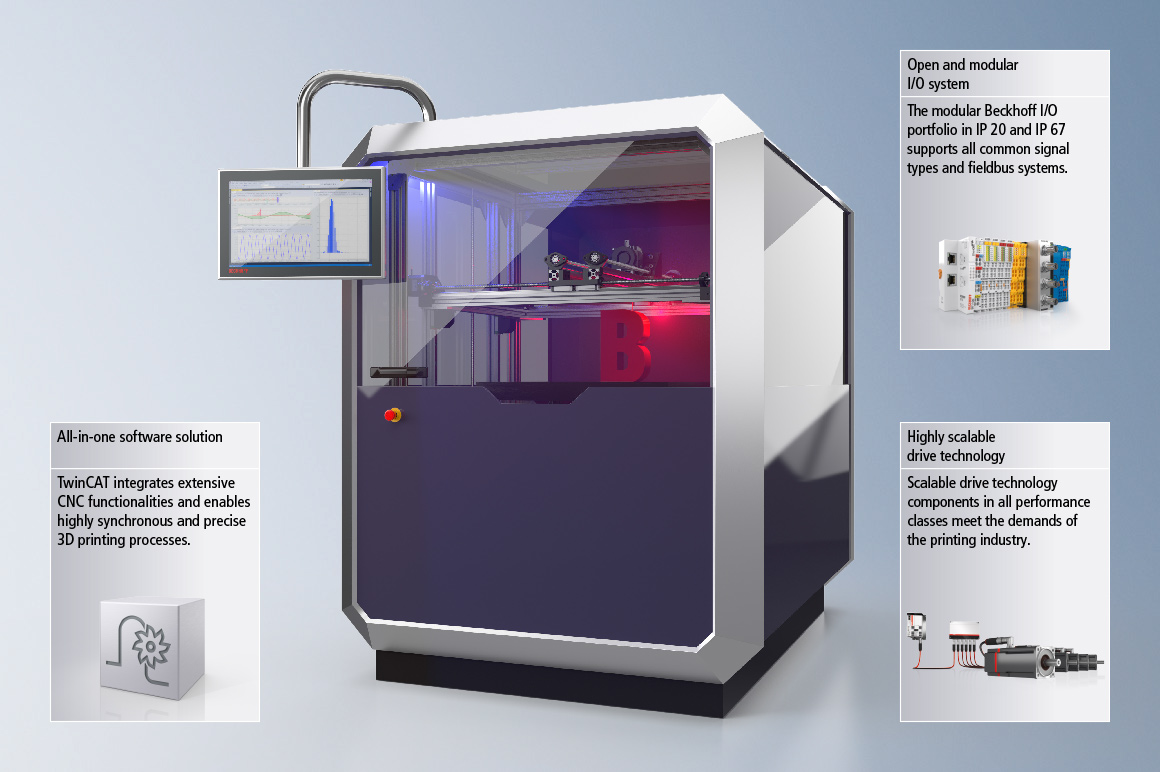

Additive manufacturing using 3D printing is becoming the process of choice for more and more manufacturers, especially for small quantities. This requires a control solution that guarantees maximum flexibility, high process speeds, and consistent quality, such as TwinCAT CNC. The all-in-one solution for engineering modern 3D printing systems supports all CNC functions. State-of-the-art control algorithms ensure highly synchronized movements.

Open interfaces such as TcCOM allow you to integrate your own process logic. Suitable drive solutions can be found in our portfolio too: The spectrum ranges from servo terminals and motors with integrated servo drives to high-performance servo drives.

Advantages at a glance:

Digital printing is developing from a former niche segment into the printing technology of the future. The process, known as non-impact printing (NIP), does not require a static printing form and offers maximum flexibility, a wide range of variants, and cost-effective production. Whether it is commercial sheetfed or web printing, label production, or packaging printing: Digital printing is suitable for a wide variety of materials and geometries, but requires open and high-performance control technology. With PC-based control, we can provide you with this technology for the entire process chain: from digital image processing to the finished product.

Advantages at a glance:

Packaging printingrequires high-quality printing images, along with sustainability and flexibility for rapid product changes. At the same time, cost pressure is increasing. The requirements also vary depending on the industry: Pharmaceutical customers expect maximum traceability, while short production cycles are important in the food and consumer markets. Personalized designs, frequent format changes, and the rapid introduction of new products require flexible machine control.

You can lay the foundation for this with PC-based control from Beckhoff. The modular and scalable platform combines all control processes for packaging printing in an integrated architecture, increases the economic efficiency of the printing systems, and strengthens your competitiveness.

Advantages at a glance: