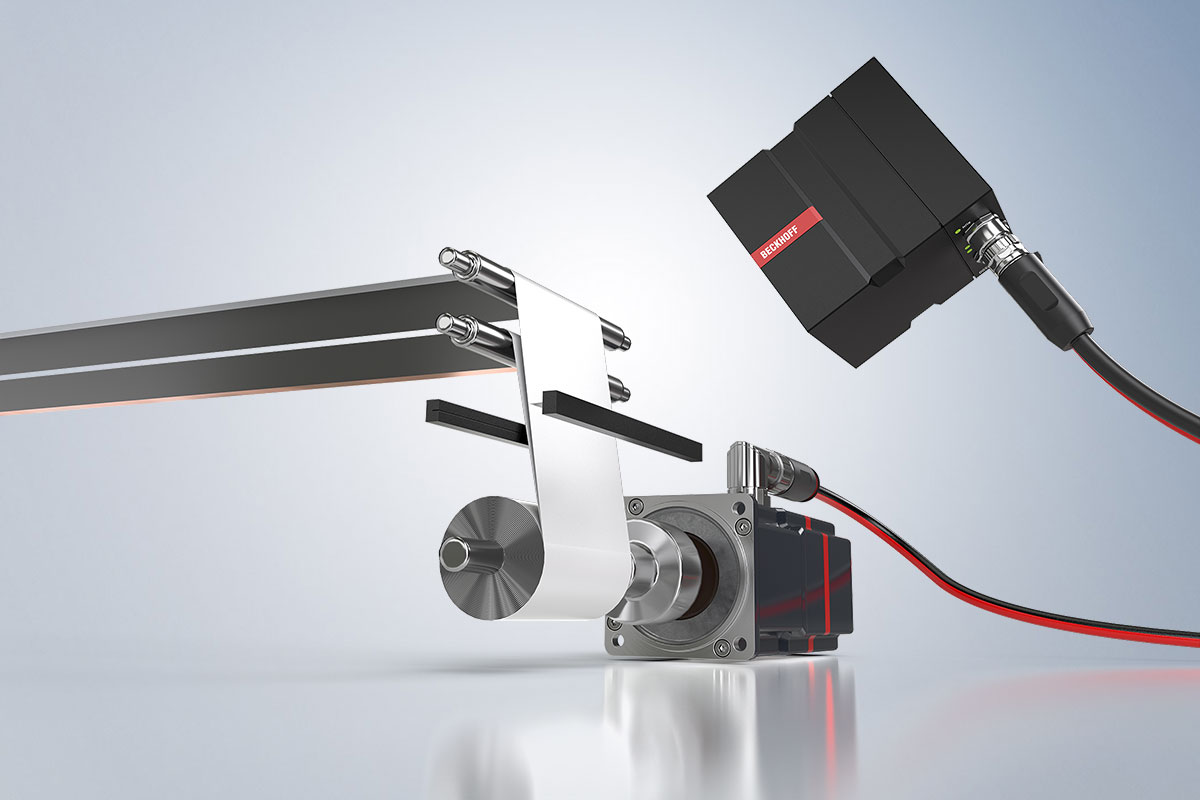

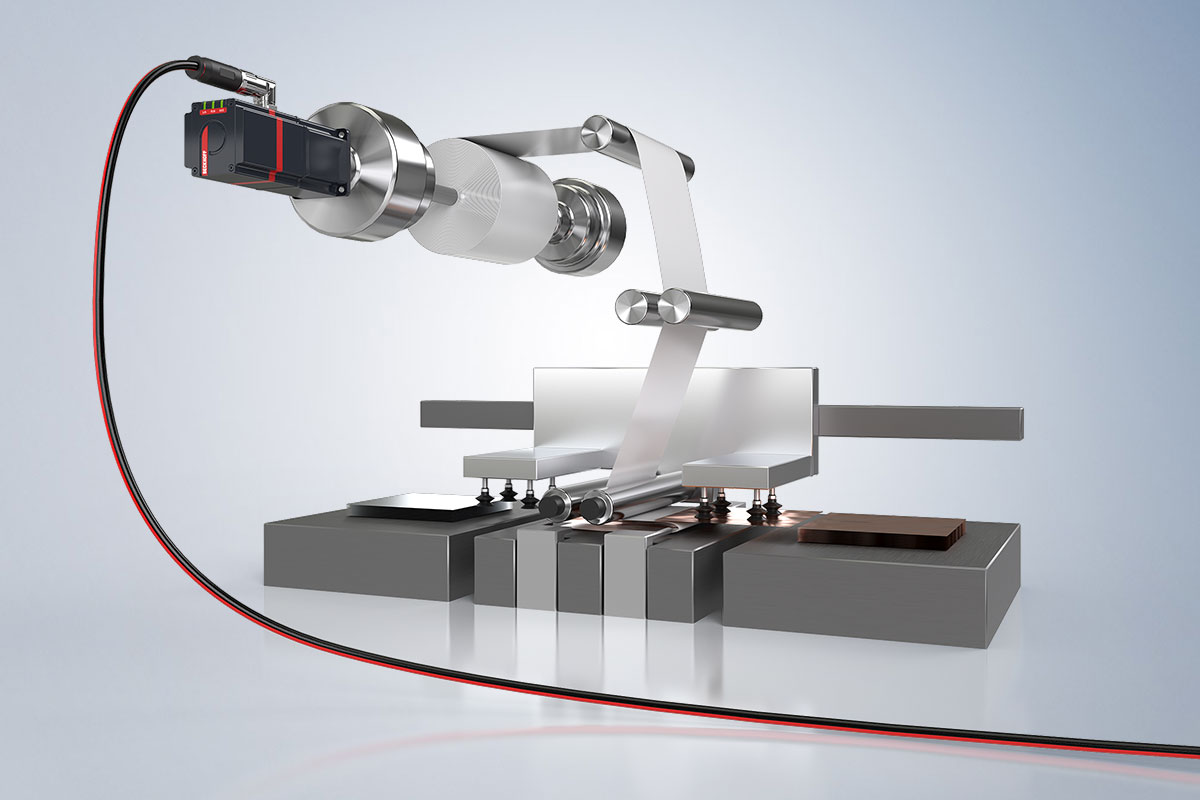

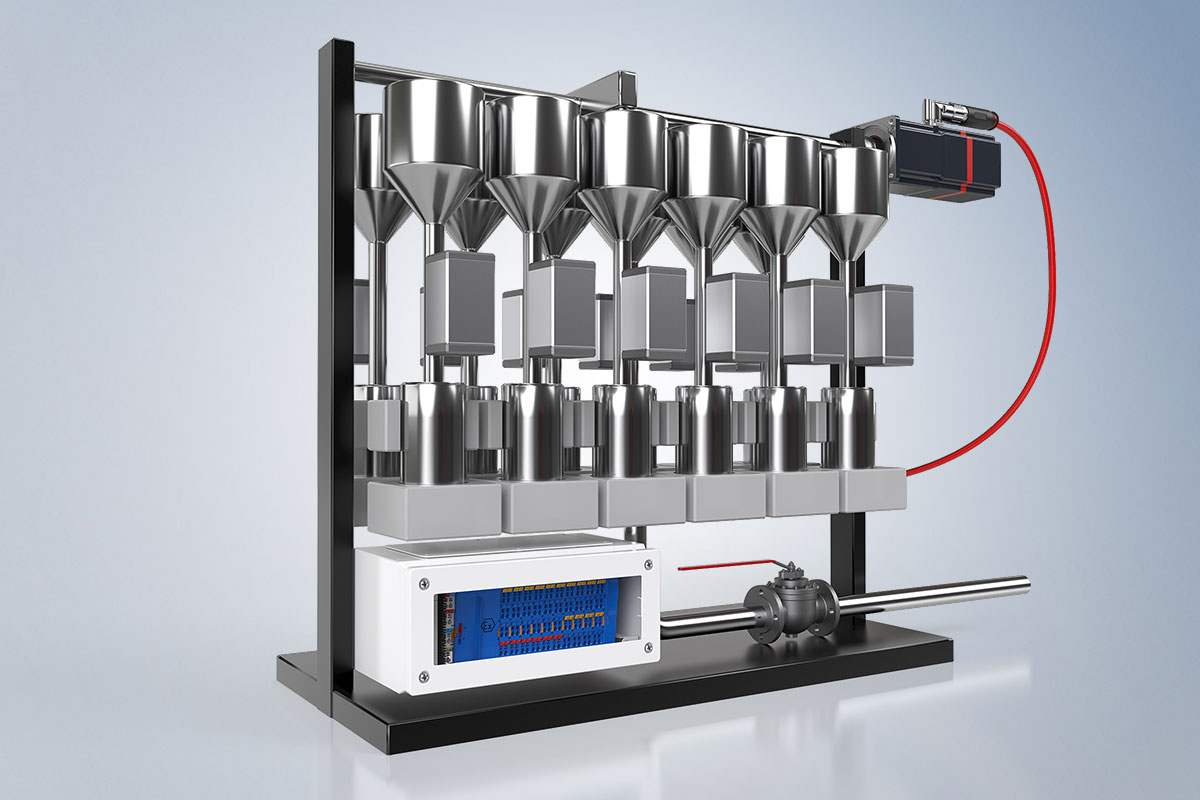

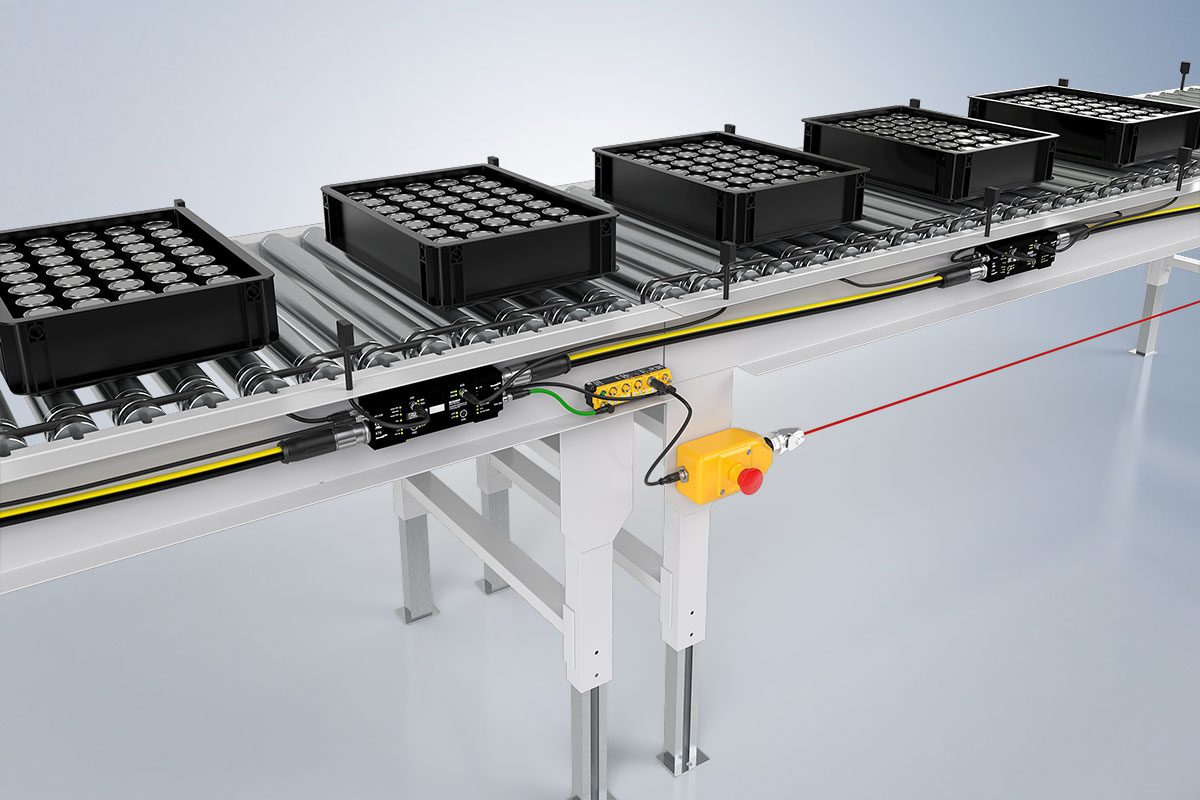

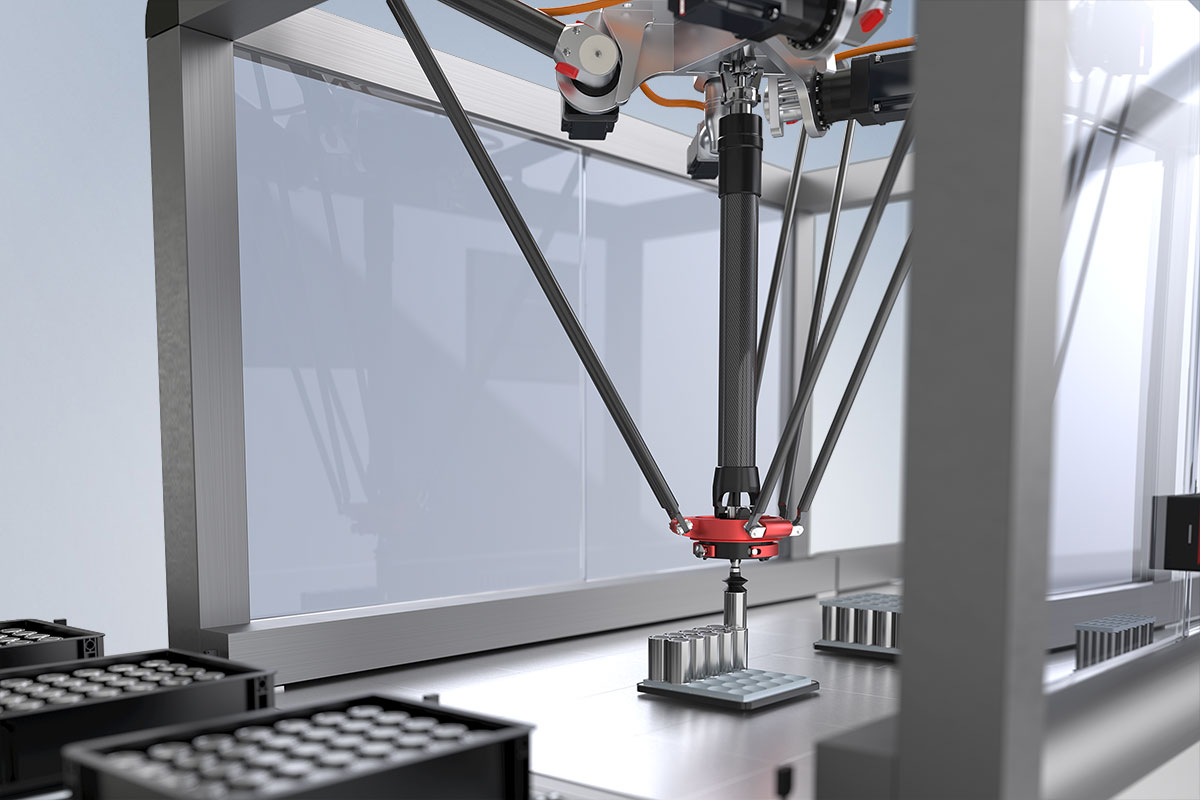

The fast-growing e-mobility market places high demands on battery cell production in terms of speed and efficiency. This is why intelligent, high-performance automation solutions are so essential. Our control technology enables end-to-end automation of all processes in battery manufacturing: from electrode production to module and pack assembly. PC-based control offers advantages for all machine types, no matter whether you produce round, pouch, or prismatic battery cells. We offer the perfect solutions for all forms of battery technology too: from lithium-polymer cells to solid-state battery cells to LFP cells.

Your head start in battery manufacturing with Beckhoff:

- high speed thanks to fast cycle times

- optimal synchronization of control functions on a single platform

- execution of sophisticated motion tasks

- flexible scalability of hardware and software