EtherCAT plug-in modules and a compact Panel PC expand controller functionality in high purity industrial gas applications

U.S. specialist company Applied Energy Systems (AES) has modernized its tried-and-tested controller for supplying production lines with high-purity gases to support its application in advanced Industrie 4.0 solutions. The CP6606 Panel PC and the compact EtherCAT plug-in I/O modules from the EJ series enable significantly increased device functionality while preserving the same small dimensions of the predecessor device.

Ultra-high purity industrial gases are essential for electronics manufacturing and research projects, but because many are highly combustible or poisonous, they can also be fatal when mishandled. This complicates the process of designing systems that handle these gases, according to David Stetz, chief engineer of controls technology research and development at AES. Although safety remains the top priority, semiconductor manufacturers, for example, must also ensure high-speed throughput while ensuring quality and accuracy in the region of half a micron or less.

Providing safe, reliable, high-performance systems has been the goal of AES since it began manufacturing high purity gas systems in the mid-1980s. Applications for high-purity gases include general manufacturing, research laboratories, solar, pharmaceutical and biotech products, while the market for ultra-high purity gases includes manufacturers of aerospace components, semiconductors and other electronics. In this high-tech environment, it is very important to continue to design new products and modernize existing equipment, says Jim Murphy, general manager of AES: “We are intently focused on research and development and expanding our manufacturing operations to support Industrie 4.0 solutions and the Internet of Things (IoT) technologies that our customers require right now.” One of the key innovations in the area of ultra-high purity gases has been the GigaGuard™ GSM-V™ controller. It monitors and regulates delivery of ultra-high purity gases and was designed specifically to replace the GSM-5™ predecessor model, which is not Industrie 4.0-capable.

New development with stringent requirements

AES introduced the GSM-5 three decades ago and installed approximately 10,000 units during the 1980s and 1990s alone. “Though thousands of these legacy products were installed, few received adequate support and maintenance, so they are approaching end of life,” David Stetz says. “In this context, a new development made perfect sense, especially to meet the trend towards IoT functionality in manufacturing. We also wanted to provide the end user with a simple plug-and-play solution and offer faster data processing, a more intuitive HMI and better networking for data transmission and continuous monitoring of gas conditions.”

The GSM-V also needs to monitor gas conditions effectively to maintain ultra-high purity levels and ensure safe working conditions. A slight lapse in the purity level could ruin an entire run of high-value products, which would result in significant financial loss. The delivery system therefore has to send out gases with at least the same purity level they had upon entry – or an even higher purity level after passing through additional filters and purifiers. Furthermore, abnormal gas conditions could be a sign of larger, potentially fatal, problems, so that real-time monitoring via the HMI and the network is essential to ensure safe operation.

A further requirement for the GSM-V project was the best possible price/ performance ratio. All of the components required to enhance the controller’s functionality needed to fit in an enclosure just 8 inches tall, 10 inches wide and 12 inches deep, which sits on the top edge of a cabinet that supplies ultra-high purity gas. David Stetz adds: “Many of these systems are hardwired in place with additional equipment built around them, such as sprinkler systems. So we could not change the form factor of the equipment if we were to maintain the drop-in replacement capability.”

PC Control impresses with compact, open system

According to David Stetz, the PC-based control portfolio from Beckhoff offers a number of well-suited hardware and software solutions, and it was the CP6606 built-in Panel PC in particular that captured his attention from the outset. “The size of this ‘economy’ IPC perfectly fit the gas delivery system’s space requirements. Not only does the panel feature a 7-inch touchscreen for HMI, but it also minimizes cabinet space by eliminating the need for an additional hardware PLC and maintains a log of active alarms that users can access via the HMI software.” The CP6606 features a 3½-inch motherboard built by Beckhoff and a fanless ARM Cortex™-A8 processor with an integrated graphic adapter. In addition, there is a 512 MByte microSD card, with the option to upgrade to a 2, 4 or 8 GB card.

TwinCAT 3 automation software runs on the CP6606 to support all control and display functions, for which David Stetz previously had to use multiple programs: “TwinCAT 3 integrates both the PLC and HMI in one platform. All of the HMI features that previously had to be programmed in a separate software package and run on a separate PC are now combined into one package. The open-platform, PC-based solution ensures that the GSM-V can communicate with any end user’s SCADA systems and send data to the cloud using the OPC UA command protocol.”

EtherCAT plug-in modules minimize space requirements and I/O wiring effort

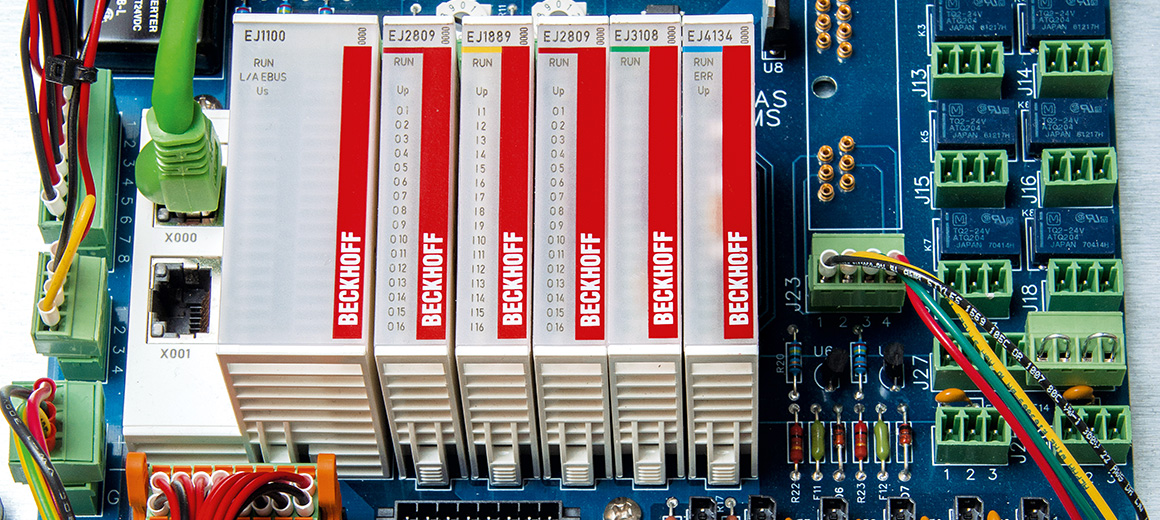

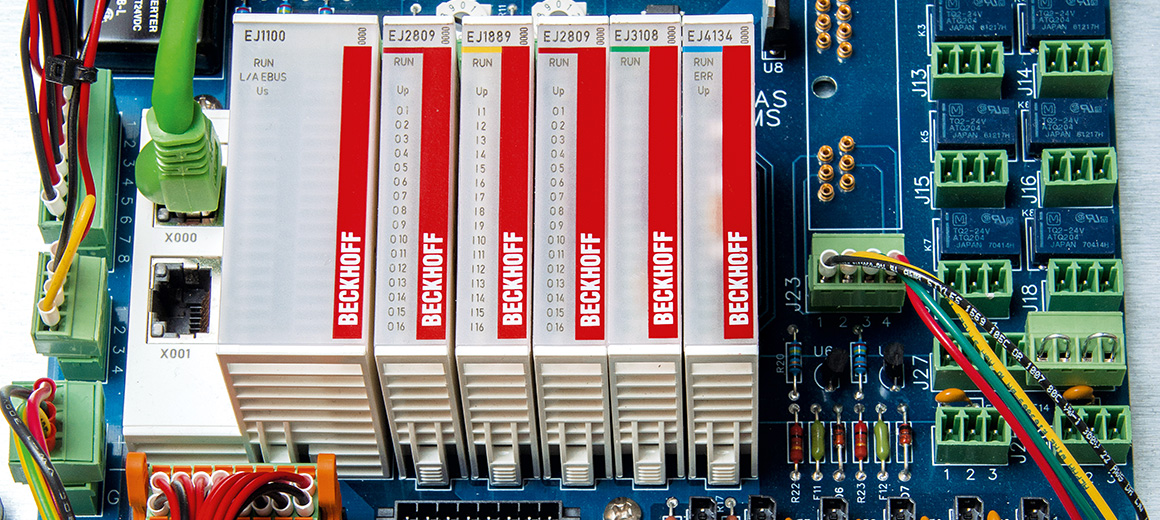

The data communication for all control and safety functions takes place via EtherCAT in real-time. The corresponding I/O level is based on EtherCAT plug-in modules from the EJ series. The GSM-V contains an EJ1100 EtherCAT Coupler, EJ1889 16-channel digital input, EJ3108 8-channel analog input, EJ4134 4-channel analog output and two EJ2809 16-channel digital output terminals. As an electrical engineer, David Stetz appreciates that he can attach the EJ series plug-in modules directly to a circuit board, which eliminates pointto- point I/O wiring, not to mention the fact that this type of installation also saves considerable space. “With other systems, I would need to have a box two or three times this size to incorporate so many I/O channels. The fact that these EJ plug-in modules are so compact and easy to install on circuit boards gives AES greater flexibility in series production, and greatly minimizes the amount of wiring and potential for error.”

Greater flexibility and reduced installation time

The GSM-V controller premiered in 2017 and since then has replaced numerous obsolete GSM-5 units. The new system meets all required safety standards, including SEMI S2, SEMI S8 and Uniform Fire Codes, and its greater functionality has been tried and tested in practice. According to David Stetz, further advantages arise from increased system flexibility, which allows standard product lines to be easily adapted to specific customer needs: “Because the GSM-V is based on TwinCAT 3, any software that runs on a PC can easily be added, as required. The Beckhoff solution allows us to demonstrate our versatility, creativity and ingenuity with new products and legacy support.”

While preserving the same dimensions and shape, the GSM-V does not retain the same cumbersome wiring requirements. Instead, the new system operates on a network connection via EtherCAT and is powered over a C13 cord, with the option to hardwire the unit if the customer prefers it. This plug-and-play solution has cut installation times by 50%, as David Stetz explains: “Until we finalized the GSM-V, we were replacing GSM-5 controllers with a different solution, and installation took at least a day due to the number of required modifications. But with the new GSM-V, our field technicians can replace two or three systems in one day.”