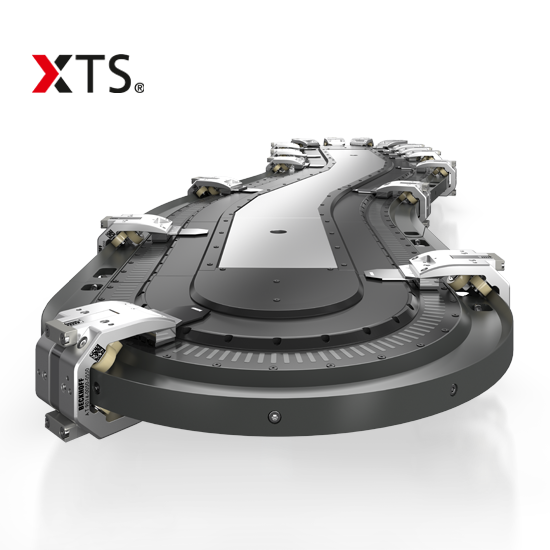

In a special exhibit, Beckhoff and other technology partners at SAP booth showcase the integration of manufacturing and administrative workflows with a production line that is based on the eXtended Transport System (XTS) from Beckhoff. It transports and positions the products individually and highly dynamically for the various process steps. The highlight: The SAP Manufacturing Execution Suite communicates directly with the XTS and other production resources on the basis of standardised services acting as an interface between different “order processing languages” the TwinCAT software connects the machine and a SAP system. The order processing communication, which is based on the service-oriented architecture (SOA) concept, is realised with OPC UA.

More about this video

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

Automatisation

TwinCAT offre de nombreuses fonctionnalités et une large gamme de blocs de fonction logiciels pour toutes les tâches d'automatisation.

Motion

Nos solutions innovantes d’entraînement offrent des possibilités quasi illimitées dans la mise en œuvre de vos applications.

TwinCAT

The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.