XTS HMI Control optimizes the XTS linear transport system

The XTS linear transport system enables dynamic and customized product transport. The collision-free and independently movable XTS movers can be positioned on customer-specific routes with high precision. Beckhoff offers end-to-end visualization solutions with a diverse range of software tools. The new XTS HMI Control for the TwinCAT 3 HMI complements the existing options with especially powerful visualization for the system operator.

XTS software tools support configuration and programming

Using the XTS View integrated into Visual Studio vastly simplifies visualizing the entire system and understanding program sequences. Together with the integrated diagnostic functions, this enables errors to be rectified quickly and early on and makes verifying the correct function of the application effortless. The Windows XTS Viewer can monitor the movements of the XTS movers in real time on the display. The user does not need to be near the system. Even with numerous XTS movers, simple functions help to constantly keep track of each individual movement.

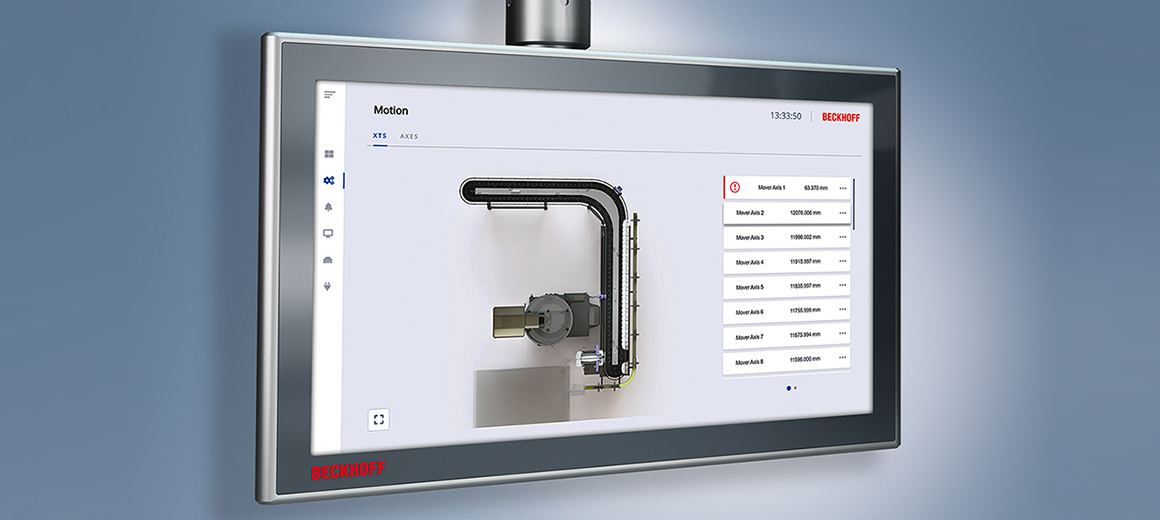

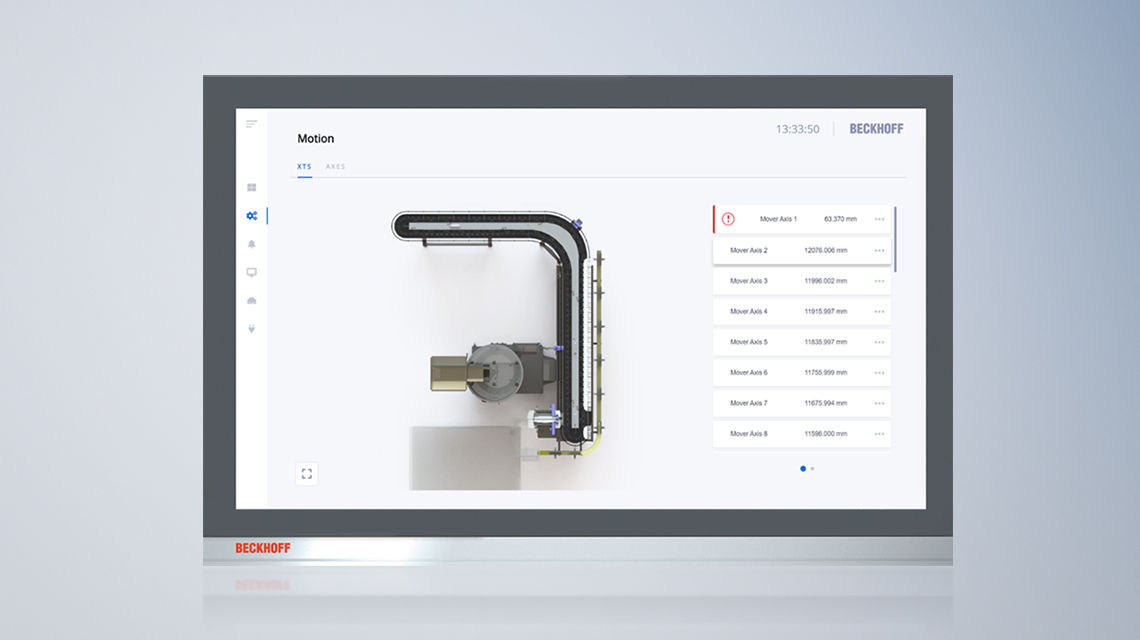

XTS HMI Control offers new visualization options for the machine operator

Now system operators can also integrate a live image of the XTS configuration into the TwinCAT 3 HMI with a single mouse click. The generated XTS HMI Control is automatically connected to all the necessary parameters of the customer's application and can directly display the current positions of all of the movers within the system.

The extensive options offered by the TwinCAT 3 HMI toolkit enable the combination with additional HMI controls or even with animated images. As a consequence, the entire system can be realistically displayed with minimal effort.

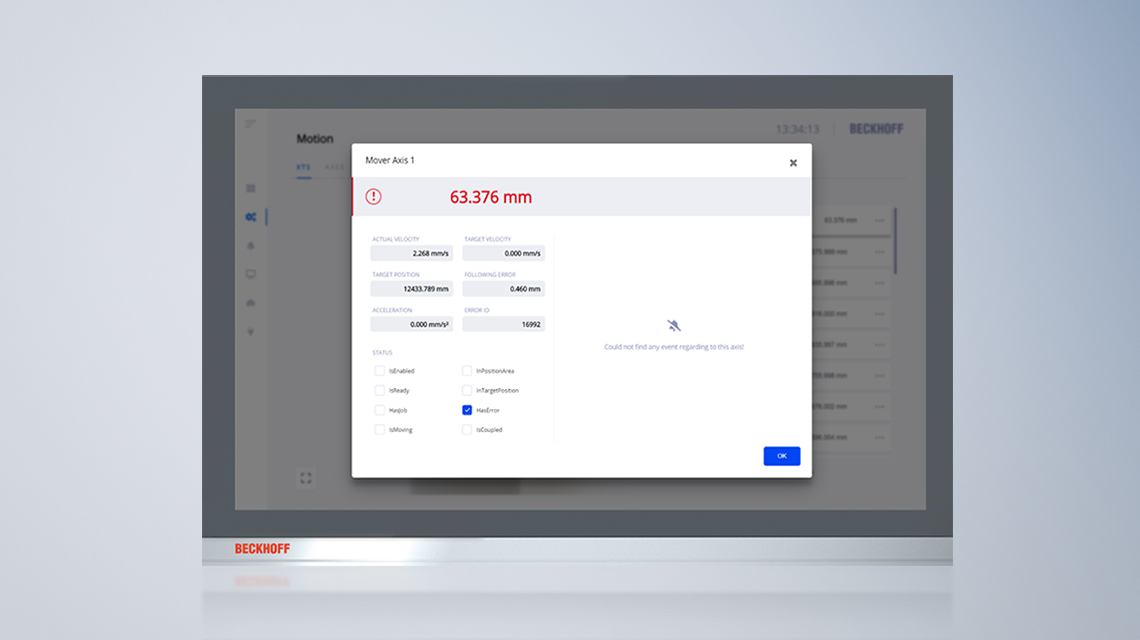

The XTS HMI Control also supports system diagnostics. In particular, it simplifies finding specific movers in complex systems by highlighting them in color. A specific error display provides an additional advantage. Error codes or maintenance notes can be displayed with different levels of detail for each individual mover and linked to the XTS View. The system’s overall accessibility is increased.