AI for the entire

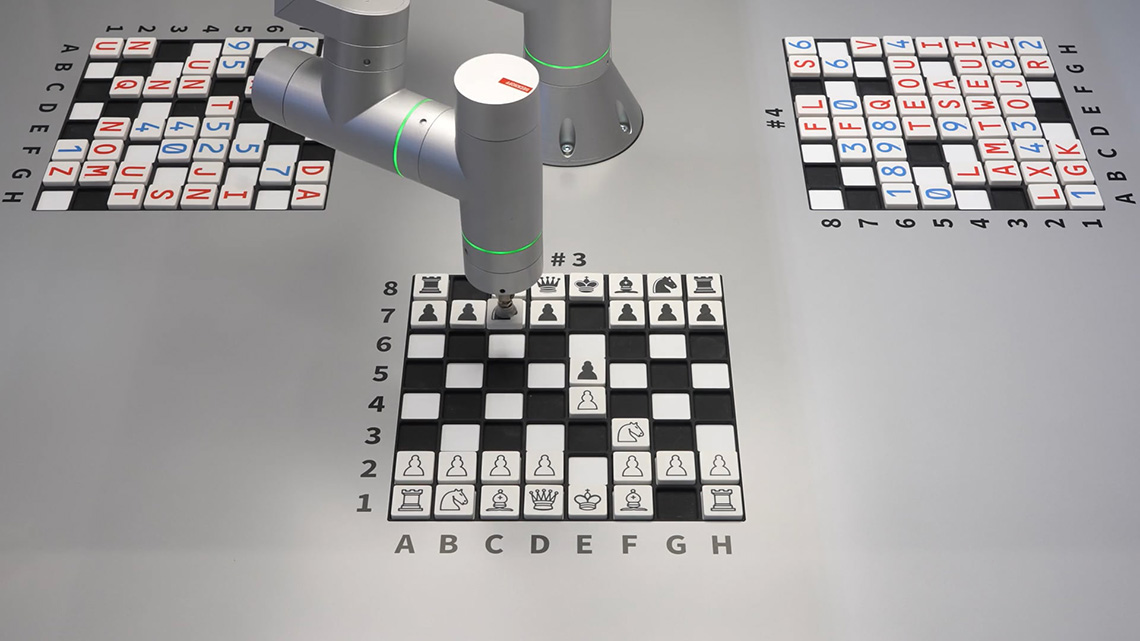

With TwinCAT CoAgent, Beckhoff offers an intelligent AI assistant that supports engineers and service personnel throughout the entire automation lifecycle. The solution combines the latest generative AI models with specialized AI agents, transforming complex engineering and operational tasks into intuitive, natural-language dialogs. It can process natural language, images, and complex technical relationships with speed and precision.

TwinCAT CoAgent addresses the key challenges facing the industry: shorter development cycles, higher quality requirements, and the shortage of skilled workers. By automating routine tasks, it allows engineers to focus on demanding automation challenges, while less experienced personnel can achieve high-quality results faster through intelligent guidance.

CoAgents for development and machine operation

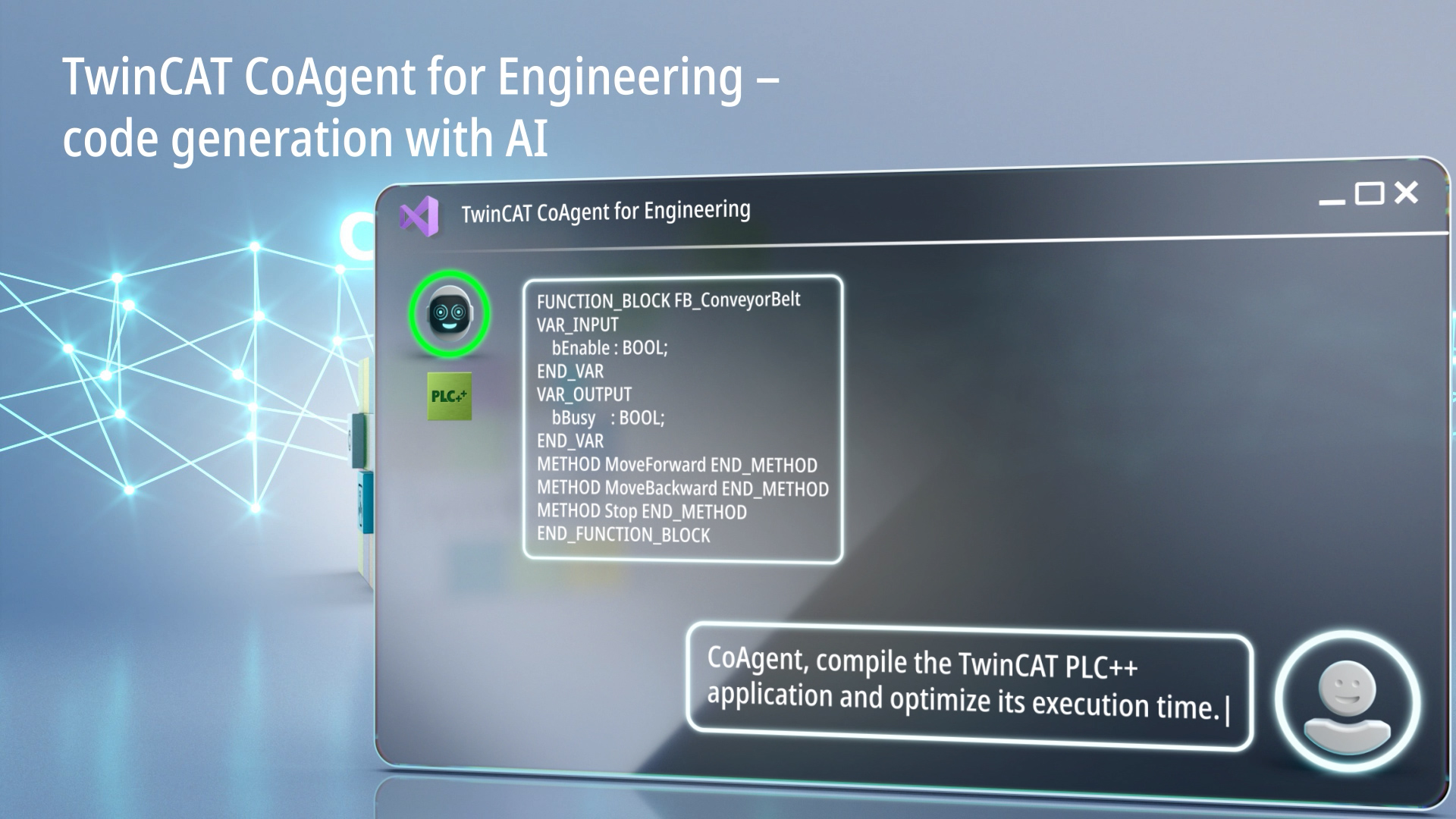

TE1700 TwinCAT 3 CoAgent for Engineering is deeply integrated into the TwinCAT 3 XAE Shell, providing uninterrupted support for developers working on PLC programming, I/O configuration, and HMI design. The software uses four specialized AI agents, each of which has its own logic and suggests specific actions:

- Simplified PLC programming

Creating PLC code becomes faster and more intuitive. Requirements can be conveniently described in natural language, and TwinCAT CoAgent suggests suitable Structured Text code based on these. Libraries and existing project structures are automatically taken into account, ensuring that all suggestions are relevant and context-specific. Integrated code search functions and simple referencing of libraries further simplify development and help improve code quality.

- Streamlined I/O module configuration

Configuring I/O topologies and communication interfaces is now easier than ever. Hardware modules can be created, named, and configured through the chat interface. The AI provides targeted suggestions for I/O configuration, helping to reduce errors and accelerate commissioning. Users retain full control over decisions and fine-tuning at all times, ensuring both flexibility and the ability to customize.

- Next-level HMI control design

With TwinCAT CoAgent, it couldn’t be easier to create state-of-the-art user interfaces. The AI assistant uses simple sketches to automatically generate complete HMI pages, identify controls, flexibly adapt design themes, and suggest appropriate code for server extensions. Automatically linking PLC variables reduces the time required during the creation process. From comprehensive layouts to small tweaks, every step can be conveniently controlled through the chat interface. The AI handles the groundwork, but the user remains in control to verify results and make individual adjustments as needed.

- Seamless integration with the Beckhoff Information System

TwinCAT CoAgent has direct access to documentation in the Beckhoff Information System, enabling the AI to search it as needed. This allows users to receive tailored suggestions and recommendations aligned with their current requirements and project context. As a result, information retrieval is streamlined, making tasks much easier.

TF1700 TwinCAT 3 CoAgent for Operations extends AI support into operations and introduces agent-based technology directly into running machines and systems. While TwinCAT 3 CoAgent for Engineering addresses the development phase, TwinCAT 3 CoAgent for Operations supports service personnel and maintenance staff during machine operation. Using the assistant results in significant advantages in the working environment:

- Access to live operating data

TF1700 accesses TwinCAT variables via ADS or the Analytics Logger, allowing it to evaluate process values, log files, and KPIs during operation. The scope and type of monitored data are configured according to the user’s requirements.

- Integration into TwinCAT HMI

The TwinCAT 3 CoAgent for Operations chat function is directly integrated into TwinCAT HMI. Operators can interact with the AI in the familiar HMI context without leaving the user interface. Analysis results, diagnostics, and live information are seamlessly integrated into the existing HMI environment.

- Structured problem-solving process

TwinCAT 3 CoAgent for Operations can support a diagnostic workflow by using AI to generate hypotheses based on symptoms and patterns, validate them with operating data, and provide concrete recommendations including troubleshooting instructions. The precise workflow and diagnostic steps can be adapted to align with the customer’s processes and expectations.

- Flexible documentation and reporting

The system can create service reports and shift logs in line with the user’s specifications, including root cause analyses, KPI trends, or maintenance tasks. The format, content, and time periods of the reports are configured according to individual requirements and workflows.

Products

TE1700 | TwinCAT 3 CoAgent for Engineering

TwinCAT 3 CoAgent for Engineering is the intelligent AI assistant that provides efficient support for PLC development, I/O configuration, and human-machine interface creation. Requirements can be formulated in normal language and TwinCAT CoAgent for Engineering suggests suitable code and configurations, taking existing project structures into account. Flexible mode selection enables custom support based on the task at hand. In addition, TwinCAT CoAgent for Engineering offers direct access to the documentation in the Beckhoff Information System and provides context-related recommendations for accelerated high-quality project implementation.

TF1700 | TwinCAT 3 CoAgent for Operations

TwinCAT 3 CoAgent for Operations is the intelligent AI assistant that provides efficient support in machine operation, maintenance, and system diagnostics. Operating and maintenance tasks are described in natural language. The CoAgent then provides specific recommendations for action, diagnostics, or direct system commands based on the current machine and process data.