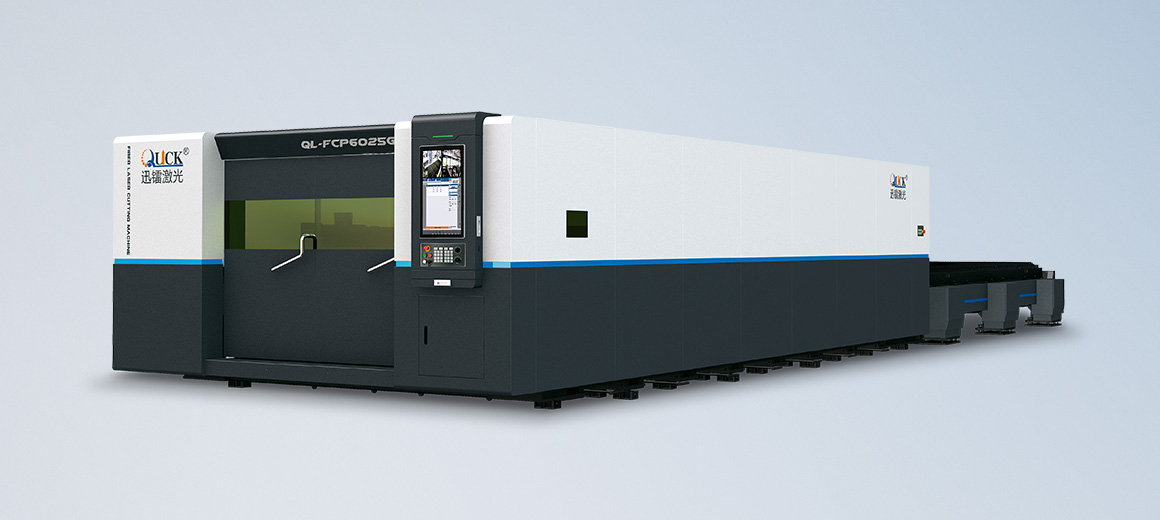

PC and EtherCAT-based control of high-performance laser cutting machines

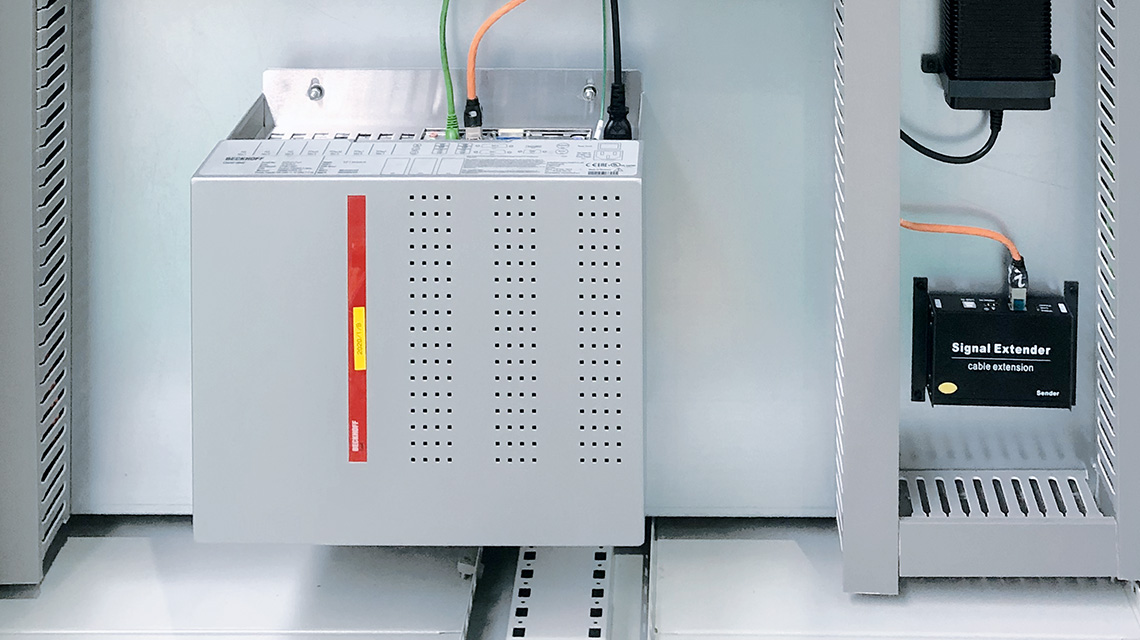

The Chinese company Quick Laser specializes in developing, manufacturing and distributing laser cutting machines. In 2016, the company commenced a strategic cooperation with Beckhoff to further boost success with high-performance laser cutting machines. PC-based control offers the optimum foundation for reliably high machine throughput, particularly with TwinCAT software as an open CNC system.

The numerous awards the company has received reflect the innovative power of Suzhou Quick Laser Technology Co, Ltd. These include National High-Tech Enterprise, Excellent Private Science and Technology Enterprise in Jiangsu Province, Excellent Enterprise in Jiangsu Province and Gazelle Enterprise in the South Jiangsu Science and Technology demonstration zone. As very demanding applications, high-performance laser cutting machines, in particular, benefit from this strong focus on technology.

TwinCAT CNC as an open system

High-performance systems like these – usually with a laser power exceeding 8 kW – require significantly more complicated machine processes than simpler designs with lower energy requirements. These characteristics include slow start, progressive perforation and pre-lasering. In addition, new technological functions often have to be implemented. According to Quick Laser, this is why an open control and CNC system is so important. This enables integration of customer-specific developments with minimal effort. Zhao Jian, Head of the Process Department at Quick Laser, explains: "Modular PLC programs and an open CNC system enable us to add and test new process functions quickly and easily. This greatly aids our success in the market for high-performance laser cutting machines."

TcCOM provides the TwinCAT CNC with an open interface to the numerical control system. This enables the optimum integration of customer-specific process expertise. As a consequence, standard control technology can be used while still allowing the integration of highly specific functions where required. The TcCOM modules are a valuable toolset for this purpose and also offer integrated and easy-to-use intellectual property protection options for users.

CNC functions and servo drives for fast cutting

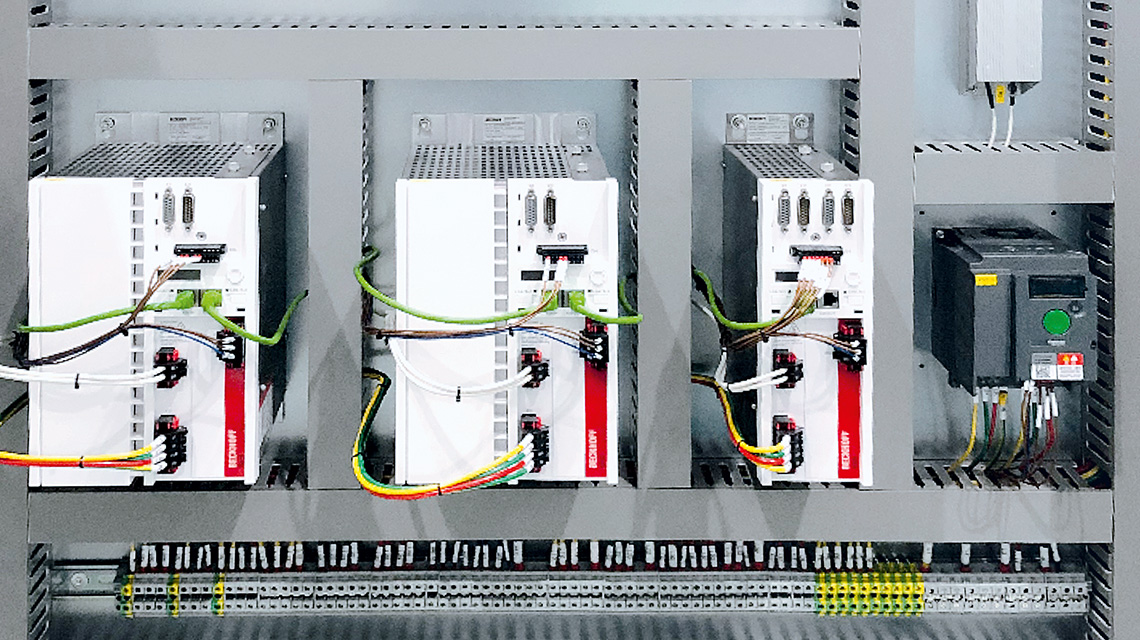

High-performance laser cutting machines are characterized by high processing speeds. Powerful servo drive technology is essential to further improve efficiency. This must cover a wide acceleration spectrum and, at the same time, must not restrict the cutting functionality of the machine tool. AX5000 Servo Drives from Beckhoff use optimized functions such as the velocity observer and TwinCAT CNC acceleration pre-control. This ensures that the consequential error for high-speed cutting is only +/-5 μm. For complex cutting of short lines such as Chinese characters, TwinCAT CNC offers a spline curve function that serves to optimize the path, improving cutting performance.

When cutting an acute angle, excessive energy density of the laser beam can result in unwanted burning. TwinCAT CNC prevents this via a corner and edge function that interpolates the space curve or enables an appropriate reduction of the laser energy. The M function offers additional advantages for extended distance output. If the workpiece falls or the edge is distorted when cutting sheet metal, there is a risk that the cutting head will collide with projecting parts and sustain damage. To prevent this, the lift functionality of the Cutting Plus package of TwinCAT CNC is used and the cutting process is therefore optimally controlled.

In addition to the C6640 control cabinet Industrial PC and the AX5000 Servo Drives, numerous digital and analog EtherCAT I/Os are also in use. For example, the EL2502 2-channel pulse width output terminal controls the laser light curtain. This EtherCAT Terminal provides a basic frequency from 1 Hz to 125 kHz as well as a duty cycle from 0 to 100% and also supports most laser products on the market. The EL6692 EtherCAT bridge terminal enables real-time data exchange with lasers that support the ultra-fast EtherCAT communication system. The EL2262 digital output terminal with eXtreme Fast Control (XFC) enables output times in the µs range via oversampling and, therefore, flying cuts.