Custom automotive machines standardized on EtherCAT and PC-based control

When building custom machinery for the demanding automotive industry, Sodecia’s Global Tech and Automation Center (GTAC) applies principles from series production. The redesign of a seat belt assembly machine is a prime example of the benefits of PC- and EtherCAT-based control and drive technology from Beckhoff, which the automotive specialist has standardized on.

Sodecia GTAC is a London, Ontario-based automation division under the umbrella of Portuguese industrial conglomerate Sodecia. In 2021, the automation specialists received an order to redesign a machine for a global automotive manufacturer. The third version of the assembly machine for seat belt height adjusters needed to deliver faster throughput, and the timeframe for development was limited.

For years, GTAC has invested time and resources in creating standardized control architectures and modular, reusable code. “Based on our control code, we turn around projects that would typically take eight months to a year in just three to four months,” says Chris Drees, Controls Engineer at Sodecia GTAC. “This also means any of our engineers can easily troubleshoot code for standard or custom machines.”

As a result, Sodecia is known to excel in tight production schedules. It’s a competitive advantage that was born out of necessity, according to Brent Lekx-Toniolo, one of the founders of the formerly independent automation group that became Sodecia GTAC. “We designed the concept of building a framework around 2000 because customers ordered machines with very quick time-to-market requirements,” Lekx-Toniolo says. In 2007, GTAC discovered the advantages of the control and networking technology from Beckhoff to make the framework a reality. “After so much trial and error with other control platforms, Beckhoff truly was the solution we had been waiting for,” Brent Lekx-Toniolo adds. “Ever since then, we've been a Beckhoff house.”

Finetuning based on standard code

Parent company Sodecia adopted many of the automation group’s innovations into its own standards, across the company’s nearly 40 manufacturing facilities around the world. Here, they have proven themselves in the design, programming and commissioning of automated assembly and welding solutions for the automotive market. “Compared to welding machines with large robots, the Seat Belt Height Adjuster SBHA#3 features much faster-paced assembly processes in a smaller footprint,” says Jesse Underhill, PLC and Robot Technician at Sodecia GTAC. “But we adapted our standard code structure – for things like dial table logic with the servo-based motion control and data transfer – to provide that functionality.” Chris Drees adds: “We also wanted to boost uptime, OEE and other capabilities, while expanding functionality by leveraging some recent updates to our standard code.”

The new machine features five sections. Two substations assemble the button for activating the seat belt adjustment – essentially a small actuator with a spring. Next, the assembly is inserted into a small steel plate with a nut that later on slides up and down a steel rail. The fourth section installs that assembly into the rail, which will ultimately be mounted to the vehicle chassis. The last section is quality assurance, so it performs height and load measurements on the components. To accomplish this, the system features two servo drives powering four servomotors, two machine vision cameras, five variable-frequency drives (VFDs), six KUKA robots, 13 solenoid valve banks and more than 100 I/O terminals. Therefore, efficient real-time control and communication was key.

The original assembly line had multiple separate cells and external conveyance equipment to transport workpieces between them. When Sodecia first redesigned the system, the GTAC engineers cut the machine footprint nearly in half to a roughly 6 x 6 m (20-by-20-foot) enclosure. “The two previous iterations produced a part every 5.4 seconds, but this one needed to reduce that to 5.1 seconds,” Chris Drees explains.

PC- and EtherCAT-based logic and motion control

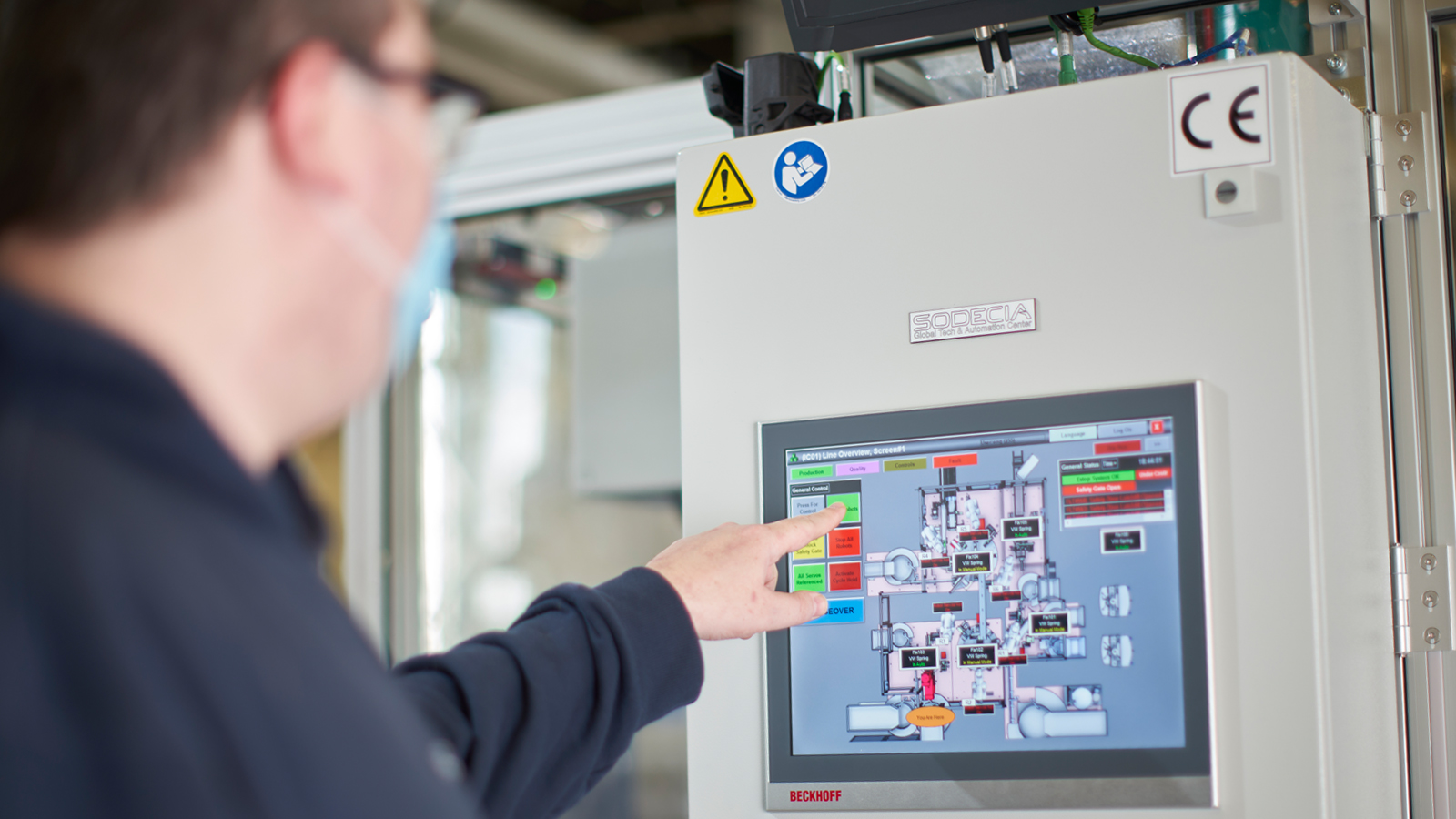

The PC-based automation approach uses TwinCAT 3 software as a flexible, universal platform to control all machine processes from PLC and robotic kinematics to functional safety and IoT. On the PC-based machine controller, other software can run alongside TwinCAT. The TwinCAT engineering environment is fully integrated into Microsoft Visual Studio™ and allows the GTAC engineers to program in the languages they are most comfortable with or that best suit the application at hand. The TwinCAT runtime is on a CP2215 Panel PC from Beckhoff, which serves as both machine controller and user interface. The 15-inch multi-touch display supports intuitive operation, diagnostics as well as troubleshooting by accessing the PLC code.

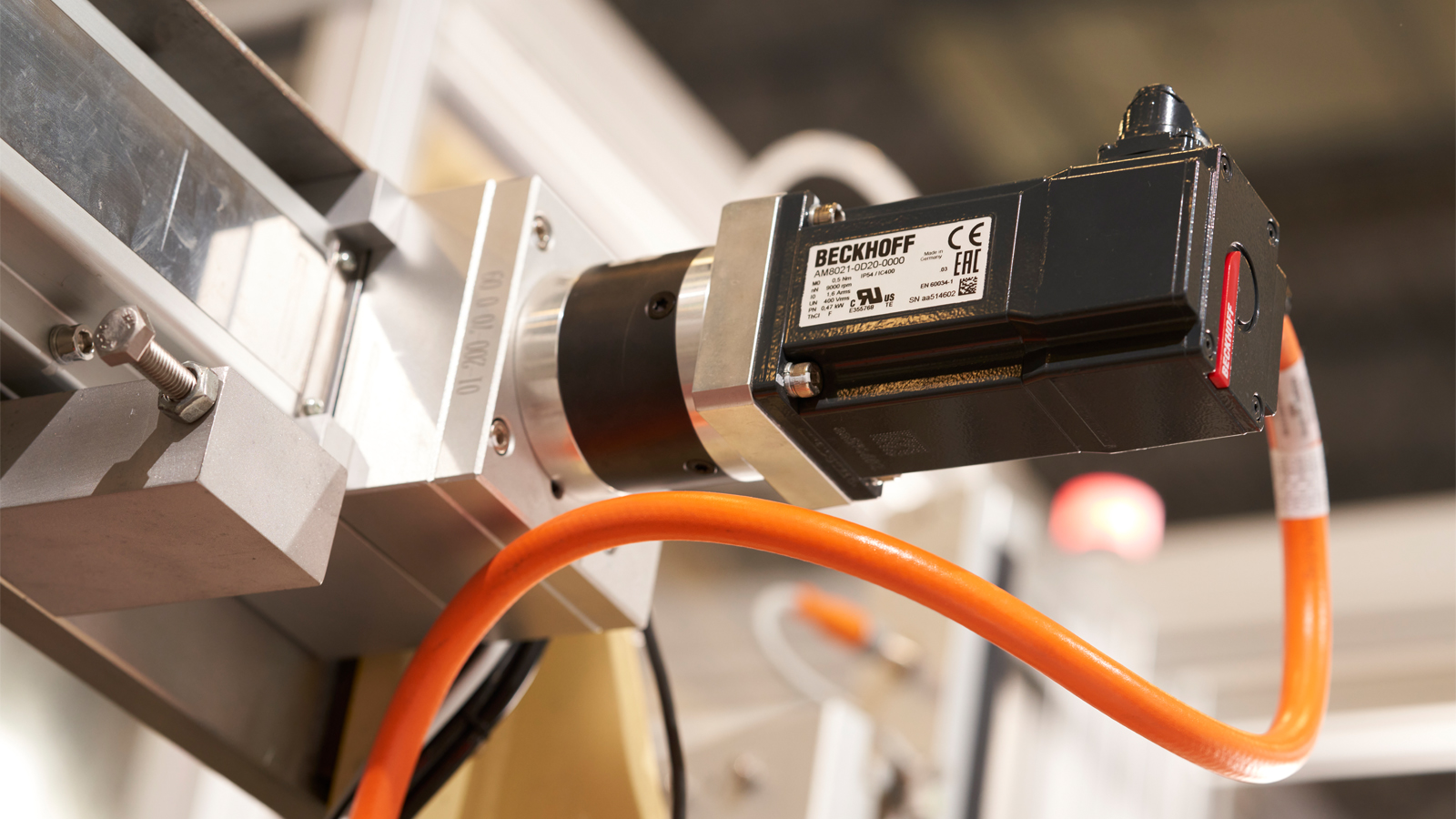

As the ideal motion bus, EtherCAT enables fast cycle times for the Beckhoff AX5000 series Servo Drives, third-party VFDs and KUKA robots. “KUKA has adopted EtherCAT, so beyond simplified communication, we can even leverage Safety over EtherCAT (FSoE) for safer systems,” Chris Drees says. This TÜV-certified safety protocol eliminates the need to hardwire safety controllers to every e-stop, light curtain or other safety device. FSoE also reduces cabling requirements because it sends safety data over the same Ethernet cables used for standard I/O. The AX5000 drives feature a AX580x TwinSAFE option card to enable functional safety right in the drive.

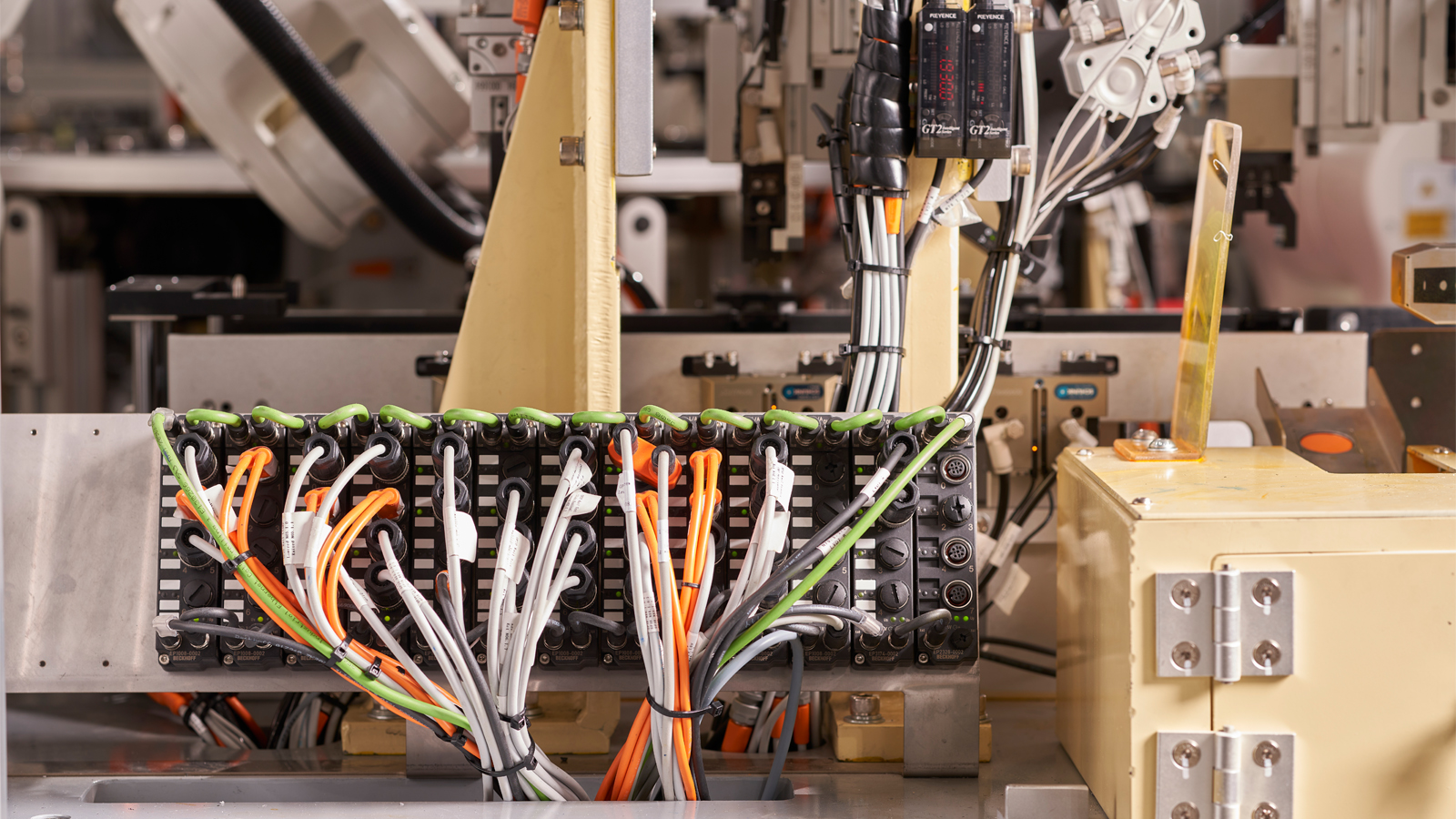

The GTAC engineers see robust diagnostics as another major benefit of EtherCAT. “When I switched to EtherCAT, I was amazed how easy it was to troubleshoot faults and errors,” says Danilo Silva, Lead of Controls at Sodecia GTAC. “Other fieldbuses I’ve used made that very difficult. With EtherCAT, you can diagnose any issue, pinpoint exactly where it’s happening and fix it.” With interfaces to more than 30 prominent fieldbuses and communication protocols, EtherCAT also simplified integration of the two machine vision cameras, which connect via EtherNet/IP, with the addition of an EK9500 Bus Coupler. This, along with a variety of EtherCAT I/O terminals in DIN-rail-mountable IP20 or machine-mountable IP67 form factors, delivered the right solution for each unique requirement.

Seat belt assembly moves full speed ahead

The GTAC engineers achieved impressive results with the new custom machine. TwinCAT automation software allowed Sodecia to make key updates to its code base, and those proved beneficial. SBHA#3 met the 5.1-seconds-per-part throughput rate, with the EtherCAT-enabled machine controller running at an impressive 125 µs scan rate. The project met a tight timeline as well – starting in September 2021, with commissioning in March 2022.

Sodecia worked closely with the local team from Beckhoff Canada – Regional Sales Manager Dean Herron and Applications Engineer Jim Fallowfield – during the project. “Beckhoff and Sodecia both started operations in 1980, and we have taken similar approaches in tirelessly developing our technologies,” Dean Herron says. “Sodecia’s modular and flexible approach to machine development goes hand in hand with our PC-based control philosophy. This allowed their team to streamline software and hardware development significantly.”