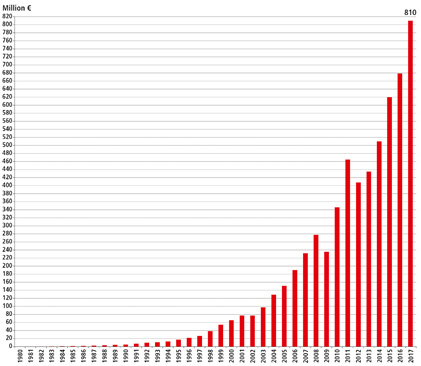

Beckhoff Automation generated global turnover of 810 million euros in 2017, an increase of 19 percent year over year. New products, a larger distribution network, enhanced production capacities and solid growth among Beckhoff customers contributed equally to these successful developments.

- Worldwide turnover in 2017: 810 million euros (+19%)

- 3,900 employees worldwide (+16%)

“2017 was a very successful year for our company. We are pleased that the growth extended across all geographical areas,” says Managing Director Hans Beckhoff. “2017 saw a robust global economy that affected all industries from general manufacturing systems engineering to building automation.” Most of the growth was observed in the Asia-Pacific region, which includes China as the fastest-growing market. But Germany and the rest of Europe saw solid growth as well.”

Extensive expansion of production capacity

“To accommodate the growth we are currently experiencing and expect to see for the rest of 2018, we significantly increased our production capacities. For instance, our capacities in primary manufacturing, which predominantly includes our circuit board assembly, increased by more than 70 percent,” explains Hans Beckhoff. Secondary manufacturing, i.e. final assembly, was also expanded for all product categories. The I/O production department moved into a new 10,000-square-meter building that doubles the previous floor space. Another 40,000 square meters are scheduled to be available by the end of 2018. With an ultimate total of 140,000 square meters of floor space, Beckhoff believes that it will be well prepared for further growth. To support these developments, Beckhoff is investing approximately 50 million euros in buildings and equipment during 2018. In addition, Beckhoff invests another 60 million euros into the development of new products and procedures each year.

For its Drive Technology division, Beckhoff has built a special servomotor production facility at its Marktheidenfeld, Germany location that comprises another 2,500 square meters of factory floor space and 1,000 square meters for offices. Hans Beckhoff explains: “By producing motor shafts and cases for our servomotors in-house we were able to significantly increase our vertical production capabilities. This step enables us to quickly respond to rising demand while further raising our in-house quality standards. Having our own production of mechanical components also simplifies and accelerates our ability to accommodate special customer requirements as well as the production of prototypes and the implementation of innovation projects.”

Customer proximity is a key factor

Also essential for the success of an automation project, says Hans Beckhoff, is the supplier's proximity to the customer, which ensures the close relationship needed to develop the best possible solutions. “We always want to be as close to the customer's location as possible. In Germany, for example, we have reached virtually seamless coverage by opening three new regional offices in Erfurt, Fulda and Mannheim in 2018,” says Beckhoff.

In addition to its 22 sales offices across Germany, the company continues to expand its global network as well, with a new subsidiary in Taiwan and a new representative office in Estonia being only the latest additions. Another subsidiary in Mexico is currently being set up. At the moment, Beckhoff has subsidiaries or representative offices in 37 countries. Counting its own sales companies and distributors, Beckhoff is represented in 75 countries.

Compared to the previous year, the number of Beckhoff Automation employees increased by 16 percent to 3,900. About 2,900 of these employees work in Germany and 2,600 are at the headquarters location in Verl. 1,400 employees have engineering degrees.

Universally applied products and technologies

Beckhoff offers comprehensive solutions in various performance categories for all areas of automation. With their high level of scalability, the company's control and drive products can be adapted to the widest possible range of applications. A major advantage, says Hans Beckhoff, is the fact that “our TwinCAT automation software combines all required machine functionalities such as PLC, motion, robotics, measurement technology, scientific automation, vision, communication, IoT functions and HMI in a single software package. This delivers a high degree of functionality and enables the customer to deploy leading-edge technology while keeping total costs in check,” says Beckhoff. At the moment, the Beckhoff engineers are particularly pleased that they were able to add image processing, i.e. machine-based vision, in the form of TwinCAT Vision software as another functional machine component. The deep integration of image processing into the control functionality will deliver many benefits to the user.

More positive developments in 2018

“Already, 2018 is off to a very good start. In the first quarter we once again posted double-digit growth,” reports Hans Beckhoff while looking optimistically into the future: “While the growth rate may be a bit more moderate in 2018, we expect it to remain at a high level. We believe that we are superbly positioned in terms of both technological and distribution-related aspects.”

Bogdan Rojc

Beckhoff Avtomatizacija d.o.o.

Zbiljska cesta 4

1215 Medvode

Slovenia