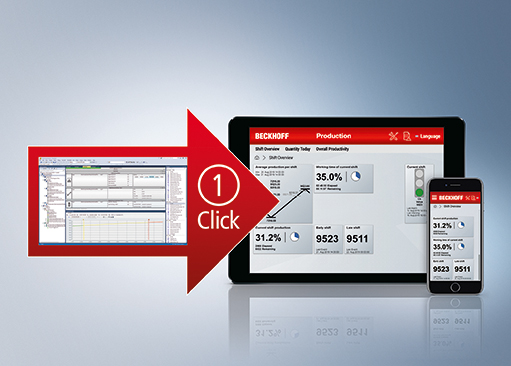

Many machine builders and systems integrators looking to transform their business models have identified machine and plant process data as being a core fundamental. When it comes to tailoring new data-driven services to individual customer requirements, however, they need solutions that are as cost-efficient as possible. Here, keeping the engineering as simple as possible is a key factor. TwinCAT Analytics supports this kind of Engineering 4.0 approach with the One-Click Dashboard, a new feature that reduces the once time-consuming process of dashboard creation to nothing more than a simple mouse click.

TwinCAT Analytics’ automated functionality for converting analysis configurations into executable PLC code now also includes dashboard generation. With One-Click Dashboard, all it takes for users to generate an entire HTML5-based analytics dashboard based on the PLC code and to load it into a selected Analytics Runtime container is a simple mouse click. When the process completes, users receive a network address that they can then use to access the dashboard in a web browser. This ability to generate dashboards without the need to write a single line of code or design graphics is a huge time-saver within the engineering process.

Based on TwinCAT 3 HMI, the new functionality provides at least one HMI Control for every TwinCAT Analytics algorithm, each with an up-to-date tile design that follows the latest web standards. The controls contained in a dashboard can be selected individually in an algorithm’s properties with the aid of a control preview. Users can also combine multiple algorithms within an individual HMI Control.

Generated automatically, tailored individually

Automatically generated dashboards can be customized by configuring individual user settings. For instance, users are able to pick their own header colors and logos, and can even choose to show geographically distributed machine locations on a world map. In addition, the controls are available in a choice of layouts and themes as well as multiple languages. It is also possible to switch between light and dark themes, and to automatically set links to methods that reset the algorithms.

Despite this high level of flexibility, dashboards that are created automatically may not always meet every user’s needs, so when TwinCAT 3 HMI projects are generated, they are integrated into Visual Studio® as well. This enables users to adapt their dashboards to their requirements in the graphical editor. Even with dashboards that need extensive customization, the engineering process still involves far fewer clicks than the conventional approach, saving significant time and expense.

Products

Bogdan Rojc

Beckhoff Avtomatizacija d.o.o.

Zbiljska cesta 4

1215 Medvode

Slovenia