Fully integrated process and building automation

Engelhard Arzneimittel is one of the leading brand manufacturers in the field of over-the-counter medicines. Its well-known products, which include the cough medicine Prospan, are sold in more than a hundred countries worldwide. The pharmaceutical company has constructed a new production building and production facilities for liquids, laying the foundation for sustainable production – with the support of PC-based control and the application engineers from Beckhoff.

150 years after its founding in Frankfurt am Main in 1872, Engelhard Arzneimittel is still a family-run company, now in its fifth generation of ownership. Around 450 people work at its site in Niederdorfelden near Frankfurt, around 100 of them in production. In 2019, Engelhard responded to the immense increase in demand it faced with the construction of a new administration building and a production building. Efficiency and sustainability were among the focal points in the process of planning the buildings. Completed in the summer of 2020 and spanning an area of around 10,000 m², the energy footprint of the production building falls below the maximum stipulated by the KfW 55 standard for new buildings in Germany – and what’s more, the new liquids production facilities are powered entirely by green electricity. The company also has its own photovoltaic system that contributes around 20% of the electricity required.

As Head of Engineering at Engelhard Arzneimittel, Rüdiger John is responsible for the automation project as a whole, from planning liquids production to implementing and commissioning it – and he works with the support of Beckhoff Systems Engineering. “Even when we first started using Beckhoff technology in our old plant back in 2014, I loved the flexibility that PC-based control brought,” states John, who also praises the cooperative nature of the work he has done with Stefan Maßmann, Andreas Wieners, and Jürgen Bolte from Beckhoff Systems Engineering.

The production plant in Niederdorfelden is designed for producing all liquid pharmaceuticals. “It handles Prospan cough syrup and other liquids, which we add to packaging formats like small pouches, and we also use it to produce cough drops,” says John, explaining the range that the plant covers. Additionally, Engelhard’s products include mouthwashes for dentists, including chlorhexidine, and suspensions for infants, such as Velgastin. “We are currently analyzing whether it would make sense to produce these products in the plant as well,” says John. Every time production switches to a new product, extensive cleaning cycles are set in motion – and this is where one of the plant’s first special features comes in. “We have created the various cleaning cycles as well as recipes for producing liquids in the TwinCAT control, and they are then brought to life in the recipe management system, which works on the basis of TwinCAT HMI,” states Stefan Maßmann, who has been working with Andreas Wieners and Jürgen Bolte to provide support for the automation project since its initial planning stages.

Cough syrup, drops and liquids

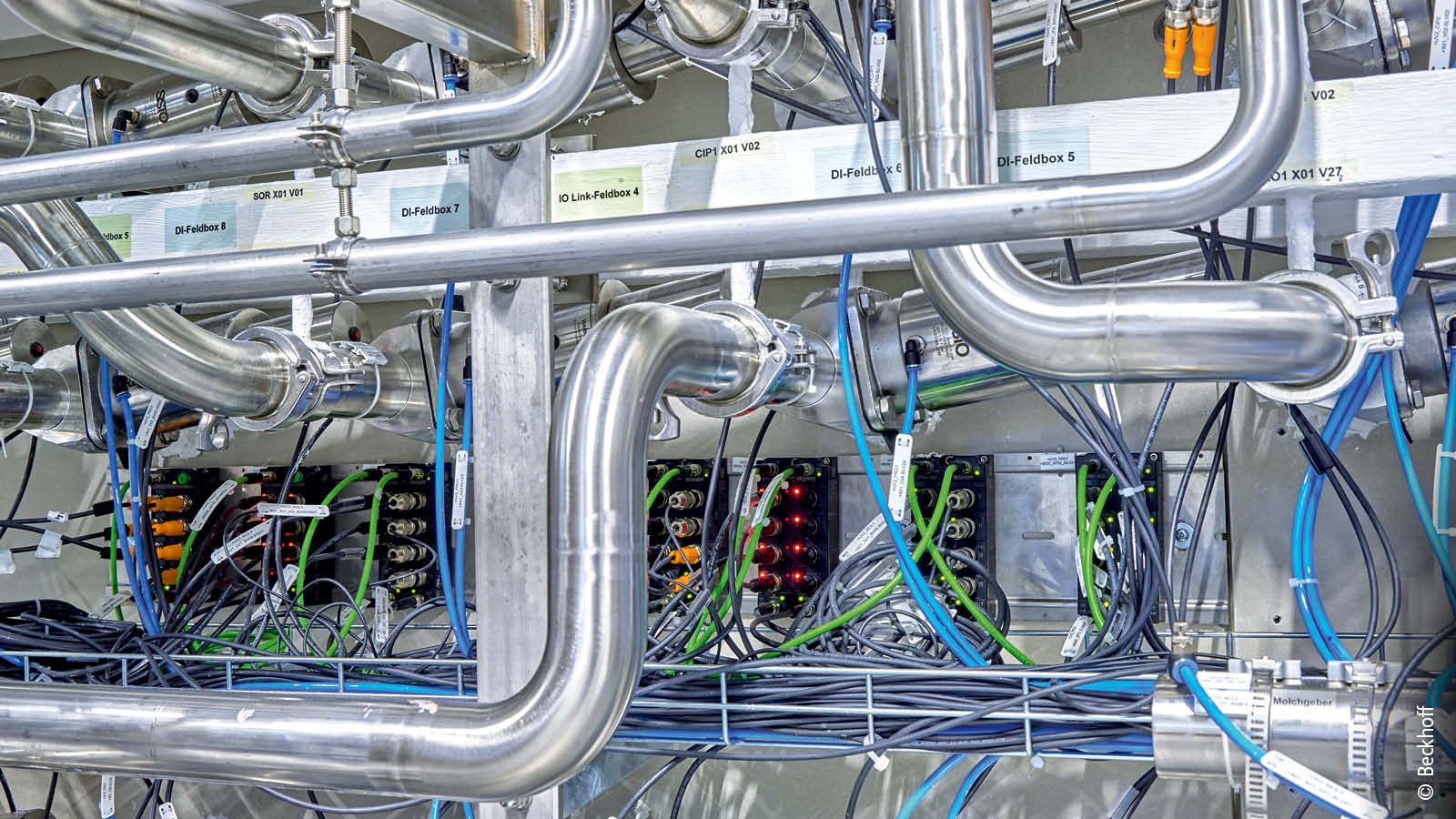

In Niederdorfelden, Engelhard produces and packages pharmaceuticals for the global market. The storage and production capacities of the new production plant are designed to reflect this scale: The five batch tanks alone comprise two containers with a volume of 10,000 l each and three with a volume of 5,000 l each. There are also additional tanks for basic substances and intermediate storage. This production area predominantly uses IP67-protected EtherCAT modules, which collect numerous signals from the sensors and actuators.

To ensure that the processes run smoothly, Rüdiger John relies on PC-based control from Beckhoff, due in large part to his experience while the production hall itself was being constructed. In this case, Elektro Beckhoff (a Beckhoff Group company) carried out the majority of the electrical planning and installation work – something that Andreas Wieners says “greatly simplified the work we needed to do on integrating the technical building equipment into our process automation.”

To illustrate this, he uses the example of cough syrup production, which requires process heating and cooling. The assemblies used to achieve this are located on the roof or in the basement and are linked to the plant via heat exchangers. Naturally, they also provide air conditioning in the production halls themselves and in the offices. Mastering this balancing act is not easy. “During the process of designing and optimizing the control engineering, it was – and continues to be – an advantage that the various technical systems are automated with PC-based control, including TwinCAT,” states Andreas Wieners. Rüdiger John adds: “With the exception of a few smaller components and in subassemblies, the entire control technology in production comes from Beckhoff, including software and engineering.”

This might be a quick summary of the equipment, but the units and assemblies involved actually make up a respectable quantity structure: To give an idea of the scale, the process automation includes 335 drives (valves and pneumatic actuators), 17 pumps and agitators, plus around 240 measuring points (for pressure and temperature, as well as mass flow meters, ultrasonic flow meters, level sensors, and so on) and 13 trace heaters. Also integrated into the technology are subassemblies such as the purified water supply, product transfer via four pigging systems, wastewater treatment, a central exhaust system, a nitrogen and argon supply, and ethanol storage, which is needed for producing alcohol-based cough drops. Numerous EtherCAT Terminals from the ELX series for explosion protection applications are used in this part of the plant, covering a wide range of process variables. The entire control technology is networked via EtherCAT and various I/O terminals distributed over several control cabinets and IP67-protected EtherCAT modules. In total, about 460 EtherCAT slaves are installed at Engelhard, including several IO-Link masters for integrating RFID read/write heads.

Process reliability and product quality come first

Rüdiger John highlights the video monitoring system integrated into the tanks as one of the standout features: “This allows us to monitor foam formation in the tanks and check the fill levels for plausibility without having to open the tanks.” Doing this prevents the pharmaceuticals becoming contaminated. A total of 16 cameras plus lighting are integrated into the plant visualization system, working on the basis of a TwinCAT HMI. If required, each operator can have the live images displayed on one of the 16 Beckhoff Control Panels and Panel PCs distributed throughout the plant. Rüdiger John had a CP3716-1076 Control Panel installed directly in the office that the team management uses. “This gives managers full access from the office without the need to connect the office IT system to the production network,” the head of engineering explains.

Each operator station has an RFID reader that production workers must use to log into the system before they take any action. In addition, the operators’ RFID chips have been retrofitted with RMD ASICs, making them compatible with the system that controls access to the building. “The tags don’t just allow the employees to log in at the operator stations and receive their authorization releases – they also provide access to the building and the production areas approved for the employees,” says John.

Working alongside Stefan Maßmann, Andreas Wieners and Jürgen Bolte, Rüdiger John defined a total of ten user profiles on the basis of the tasks associated with each and implemented them in the TwinCAT HMI. The profiles cover everything from packers and plant operators to systems engineers and laboratory technicians.

Manual hose station integrated into control system

With regard to safety, Rüdiger John has come up with something particularly special for a sensitive area of the plant: the hose station. Even though everything else is almost completely automated, in this case the various containers are still connected manually using hose connections. It is another area in which the automation engineers rely on RFID technology, as this provides a reliable way of detecting incorrectly connected hoses or missing end closures. Tags on each hose and RFID readers at the line connections make all the components and their position in the process uniquely identifiable, ensuring consistent quality and process control.

For each production process, the visualization and control systems store all the hose connections that employees have to establish by hand, in a way that is comparable to recipe instructions (“take hose 5 and use it to connect nozzles four and eight”, for example). Only when all hoses (tags) are located at the correct nozzles (RFID readers) does TwinCAT enable the next process step: for instance, pumping a batch to the storage tanks for the filling and packaging lines one floor below. “We can even use the tags on the hoses to check things and make sure we’re only using hoses that are suitable for the media and have been cleaned beforehand,” explains Stefan Maßmann. If an employee does happen to make a mistake in connecting everything together, TwinCAT recognizes this immediately on the basis of an invalid tag ID and interrupts the process step until the employee has made the correct hose connection and acknowledged it.

The plan is to install some of the 50 RFID readers in the hose station. “We want to tackle that in the near future,” states Rüdiger John, looking ahead to the next stages of expanding production. His roadmap also includes areas such as linking production planning to campaigns and demand forecasts from the higher-level ERP system. “At some point, we want to implement recipes from within SAP,” adds John, explaining one way in which things are set to expand. In his view, the open and flexible PC-based control platform will also make this integration a breeze.