EtherCAT Box modules from the EPX series used with painting robots

b+m surface systems GmbH, based in Eiterfeld in Germany, plans and builds complete painting systems – encompassing the process, conveyor, and application technology. The company’s extensive expertise results in particularly application-oriented solutions. This is exemplified by the 6-axis articulated robots from the T1 X6 and T2 X6 series, which have been specially optimized for paint application and are particularly easy to maintain due to the use of EtherCAT Box modules from the Beckhoff EPX series, among other things.

The painting systems are mainly used in the automotive industry, for commercial vehicles, and in the aviation industry. Bernd Käsmann, Head of Application Technology at b+m, explains: “For us, a complete painting system encompasses all aspects from infeed of the raw part to acceptance of the finished painted component. This includes everything from preparing the quotation and detailed engineering to commissioning and running in the system. Our core competence is application technology, for which we develop our own solutions with a high level of vertical integration, from atomizers to robotics and dosing technology through to paint supply.”

An important element of the application technology is the robot with the paint atomizer. This includes the T1 X6 and T2 X6 series painting robots – modern 6-axis articulated robots with hollow wrist for internal media feed to the atomizer. The larger T1 X6 version is mainly used in automotive plastic painting systems, while the smaller T2 X6 is particularly suitable for limited painting areas or installation positions dictated by the process. According to Bernd Käsmann, the entire robot concept is tailored to the requirements of the painting sector. Various directives, e.g., ATEX, must be complied with for use in hazardous areas. To fulfill these requirements, pressurized enclosures (Ex p) are used.

Intrinsically safe signals seamlessly integrated into control technology

With the new X6 robot generation, the IP67 I/O modules of the EP and EPX series from Beckhoff offer advantages from both a developer and user perspective. Bernd Käsmann explains: “In the previous models, the cable routing system was not clearly defined, so from the very beginning we had to determine exactly which media, hoses, or cables needed to be routed away from the robot. With the EtherCAT Box modules of the EPX and EP series installed directly inside the robot, this work was reduced significantly. And this fits in very well with the overall concept, as the X6 generation is particularly characterized by its ease of maintenance and high system availability.” He summarizes the specific advantages of the EPX modules as follows: “The greatest savings result from the reduced number of lines that need to be routed from the robot to the application cabinets. This means significant space savings in the hose package. Added to this are the simplified and centralized installation and the maintenance-friendly overall design.”

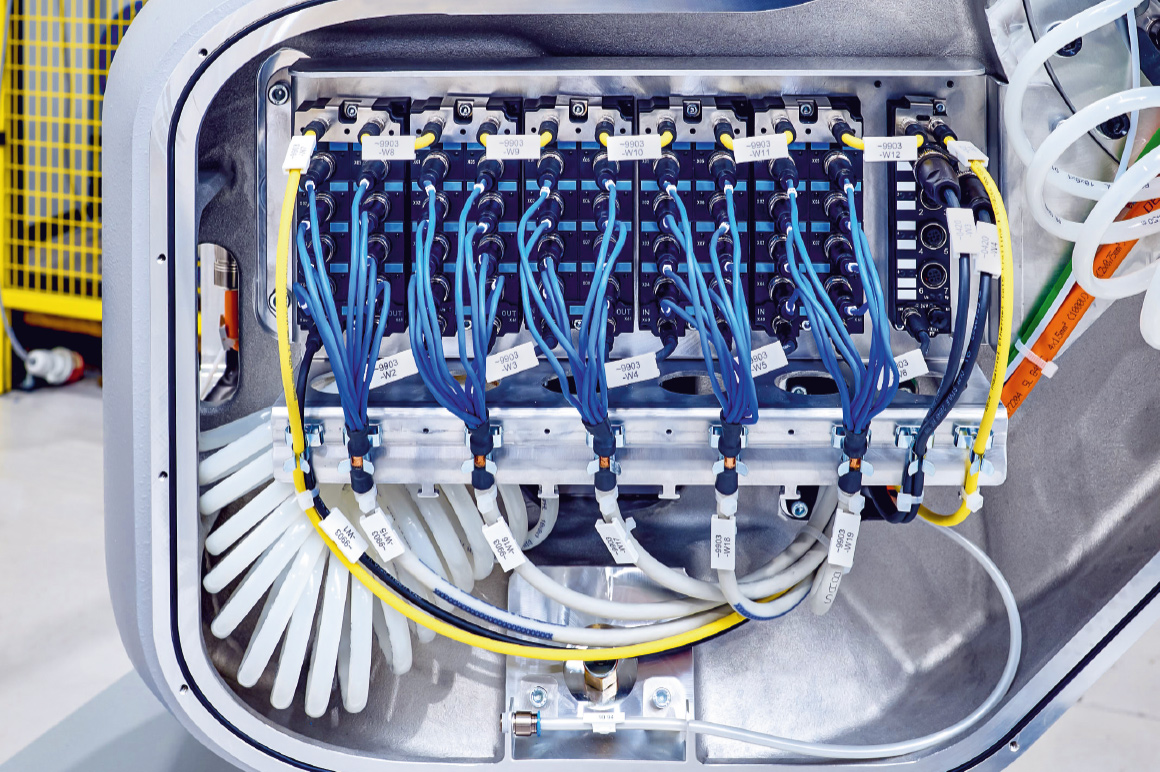

The starting point for using the EPX modules in the painting robots was the requirement to implement an IP67 I/O level with integrated intrinsic safety in a small installation space – achieved in the T2 X6 painting robot, for example, with four EPX1058 EtherCAT Box modules (8-channel digital input) and, depending on the configuration, one or more EPX3158 EtherCAT Box modules (8-channel analog input). Both I/O Box modules allow intrinsically safe field devices from hazardous areas of zones 0/20 and 1/21 to be directly connected.

Andres Oetken, who works in process industry management at Beckhoff, explains the development of the EPX modules: “The idea of using IP67 I/O modules to integrate intrinsically safe signals had been around at Beckhoff for some time. The first implementation was then realized in connection with the b+m robot project.” According to Bernd Käsmann, the starting point was the optimization of the X6 robot generation’s internal components, which resulted from customer feedback on the previous generation. In addition, the digital and analog signals that had previously been captured through individual wiring were to be fully integrated via EtherCAT, since this allowed significant savings in material and space: “Among other things, all valves in the robot were converted to EtherCAT-based control, as were the up to 40 process technology sensors in the robot’s process arm. These are primarily digital sensors such as position encoders and rotary encoders as well as pressure sensors upstream and downstream of the paint pump. Previously, all these sensors were connected via individual cables that ran along the outside of the robot and out of the hazardous area into the application cabinets. As a result, the hose packages could reach very large diameters. With the desired cross-section, two hose packages would have been required for all lines as well as the medium- and air-carrying hoses. And this could be avoided due to the EtherCAT-capable sensors, which required significantly less wiring work.”

Special requirements for I/Os and connection technology

As the robots are approved for Ex zone 1 and are therefore intrinsically safe to operate, a solution suitable for such applications was required as an EtherCAT-capable I/O level. An additional IP54 housing would have been required inside the robot for implementation with the IP20 EtherCAT Terminals from the ELX series. Bernd Käsmann explains: “The robot’s requirements as a pressurized enclosure system would have made active air purging of the I/O housing necessary. This is difficult to reconcile with the IP54 protection rating. With the EtherCAT Box modules from the EPX series, however, we were able to avoid this conflict.”

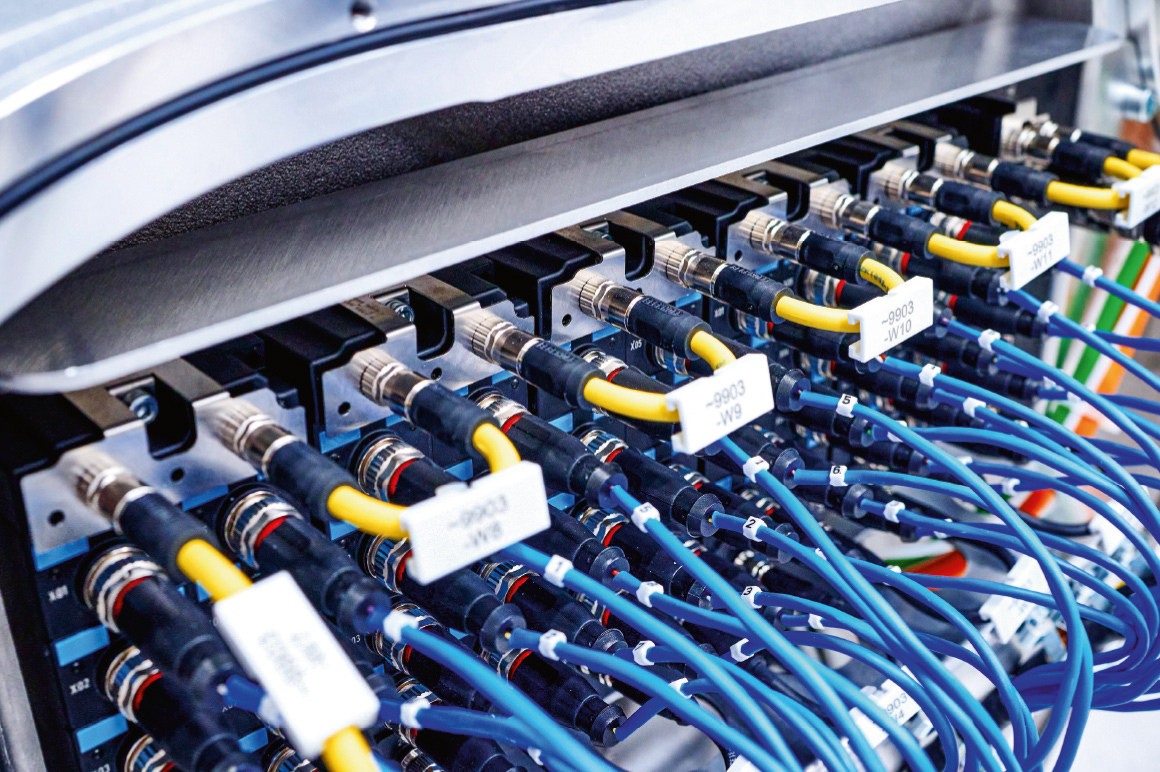

To ensure reliable signal acquisition, the challenge was to find a torsion-resistant, shielded, and slim cable suitable for installation inside the robot. Furthermore, the eight M12 connectors that are required had to be connected to the cable in a watertight manner. Beckhoff developed a solution for this where pairs of wires were individually molded onto M12 connectors. With this individual wire overmolding, a particularly space-saving, IP65/IP67-protected sensor cable was provided, which fits perfectly with the compact footprint of the system – as Bernd Käsmann confirms: “The solution developed together with Beckhoff was intended to combine eight channels in one cable in order to save installation space. Other important aspects for us were EMC shielding, twisted pair design, the smallest possible diameter, overmolded connectors to ensure IP protection, a terminal strip for initiators, and double-sided assembly for time-saving wiring.” Easy accessibility, without having to open the entire robot, and the availability of cables in all required configurations and lengths were also crucial. And no other provider has been able to implement all of this.

Flexibility through diversity with PC-based control

Openness, scalability, and component diversity are key features of PC- and EtherCAT-based control technology from Beckhoff. In addition to the EPX modules, EtherCAT Box modules from the EP series are also used in the robot, e.g., the 8-channel EP2338-1002 for recording digital signals and the 1-channel EP5151-0002 encoder interface for controlling the gun valves and for speed evaluation in the high-rotation atomizers. Bernd Käsmann also confirms the advantages of the wide I/O spectrum, including EtherCAT and TwinSAFE Terminals from the EL series in the application cabinets: “b+m benefits from the wide variety of I/Os and communication advantages in all areas of application, whether due to the simple integration of third-party components or with the components for the direct integration of intrinsically safe signals, without having to use separate, costly, and installation-intensive safety barriers as with conventional solutions.

These are good reasons which explain why b+m has been using PC-based control from Beckhoff since 1996. According to Bernd Käsmann, the decisive factor at the time was being able to use TwinCAT software as a very powerful and flexible control technology: “Our company is extremely flexible – we develop customized painting systems and the Beckhoff product portfolio offers us precisely this flexibility. EtherCAT is also an important factor due to its high market penetration, high performance, and openness to other fieldbus systems. Overall, performance limits for automation are no longer an issue in our applications with the Beckhoff system.”