PC-based control from Beckhoff as the basis for new technologies in the plastics industry

The plastics industry is facing a multitude of challenges: More competition, faster development cycles, and increasing demands in terms of efficiency, flexibility, and sustainability. Accordingly, machine builders are faced with the task of continuously optimizing and adapting their production processes. A practical technology demonstrator exhibited at the K 2025 international trade fair in Düsseldorf will show how this can be achieved with the help of PC-based control, EtherCAT communication, and the use of new technologies. Resulting from a collaboration between Beckhoff and the Japanese machine builder Nissei Plastic, the injection molding cell will also feature the XPlanar planar motor system and AI-based image processing.

Whether packaging, electronic housings, or complete dashboards: Plastics are an integral part of advanced society. And the machines that produce them are just as versatile as the end products. The range extends from compact systems to massive machines with clamping forces of more than 7,000 t. The Japanese injection molding machine manufacturer Nissei Plastic Industrial Co. Ltd. from Nagano Prefecture tries to cover as wide a part of this spectrum as possible. The machine builder is focusing on innovative, future-proof technology, as highlighted by the decision to convert its control platform to an open architecture.

Nissei relies on PC-based control

Given that the OPC Unified Architecture (OPC UA) is becoming the most important standardization framework for Nissei Plastic, the company will – in future – rely on a flexible and open control system based on Beckhoff Industrial PCs with TwinCAT software and EtherCAT communication. As part of a comprehensive benchmark study, the machine builder determined that this combination was best suited to the current requirements.

The production of injection molded parts with the highest possible repeatability and quality requires an absolutely deterministic system with cycle times of 125 μs or less. The required performance is ensured by implementing PC-based technology from Beckhoff and the Beckhoff TwinCAT automation software for real-time control. What’s more, EtherCAT has been a de facto standard for open communication in Japan for many years. This offers Nissei Plastic significant flexibility in selecting the most suitable suppliers and components for its injection molding machines.

Much more than just control technology

Beckhoff therefore offers a control solution for plastics machines that is scalable and open to other programs, protocols, and functions. However, the added value for the machine of Nissei Plastic reaches far beyond these features: The use of advanced industrial PCs with powerful processors makes PC-based control extremely fast and enables the direct integration of future-oriented technologies such as vision, robotics, or AI. Nissei Plastic also places stock in these advantages.

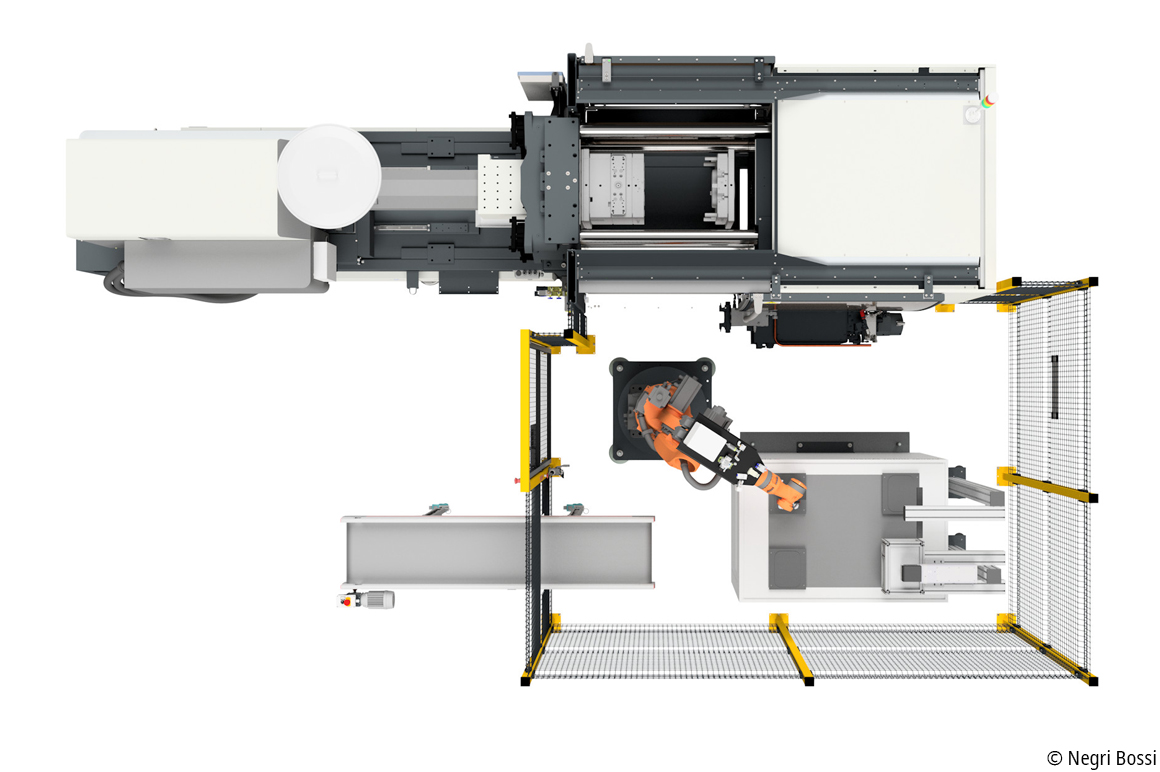

Together with its subsidiary Negri Bossi, the machine builder will show what this means in concrete terms with a technology demonstrator at the K trade fair in Düsseldorf from October 8 to 15, 2025. The comprehensive injection molding solution with integrated, highly advanced quality control combines several Beckhoff products and technologies. The backbone of the system for handling the manufactured components is the XPlanar planar motor system. Floating 2D product transport opens up a whole host of new possibilities in machine and system engineering. Individual goods can be transported highly flexibly to any location using planar tiles arranged in any order – within a machine or between several processing stations – and with the dynamics of a linear motor.

Nissei Plastic also uses the resulting, cycle-time-optimized linking of individual production steps in the exhibition demonstrator. The injection-molded components are placed onto individually movable XPlanar movers by a robot. They are then moved under a camera that captures each workpiece and analyzes the quality using AI. The result of the AI analysis and the visualization of the decision-making process – i.e., the explanation of an AI decision – are prepared in a user-friendly way in TwinCAT 3 HMI. The planar motor system also measures the weight during transport. Depending on whether it is a good or a bad part, the workpiece is either taken by the movers to be lasered with the QR code and conveyed further or sorted out. The decisive advantages over traditional approaches – greater dynamics and productivity combined with greater flexibility in the machine layout and entirely wear-free transportation – also hold immense potential for efficiency and quality in the plastics industry. For Nissei Plastic, another crucial aspect is that XPlanar enables easy integration of other quality control processes.

Developing the right AI model

The machine builder also relies on the Beckhoff portfolio for image processing. TwinCAT Vision has seamlessly integrated the image processing function into TwinCAT since 2017. This was followed by a comprehensive range of hardware for industrial vision solutions in 2022, providing machine builders and end users with an integrated image processing system that covers all necessary areas from software to illumination. What’s more, it can be integrated directly into the control technology without interrupting the system and is perfectly synchronized via EtherCAT. This eliminates the previously strict, but now outdated, separation between vision and automation technology – providing real added value with regard to Nissei Plastic’s commitment to open architecture.

The machine builder also uses TwinCAT Machine Learning Creator for image processing, which facilitates the automated creation of AI models. This allows users to handle the entire process, from data collection to the trained model, themselves – without any AI expertise of their own. The AI model is automatically adapted to real-time requirements in the control environment in terms of latency and accuracy. In this case, it took only a small number of good and bad parts to successfully train the application-specific AI model.

A partnership for the future

With PC-based control from Beckhoff, Nissei Plastic has found a powerful and flexible basis that enables the desired open control architecture to be implemented and encompasses all advanced automation technology disciplines. PLC, motion control, and vision run on one platform and are synchronized with high precision via EtherCAT. TwinCAT even makes the future topic of AI manageable for machine building users. “Together with Beckhoff, we have created an automated and stable evaluation system that works independently of production staff and takes the entire process to a new level with AI-supported quality controls,” says Isamu Komamura, Director at Nissei Plastic, summarizing the benefits for end customers. “The key features of the transport solution based on XPlanar are the flexible process interlinking and the seamless integration of weight measurement and image processing.” Looking to the future, the Japanese company intends to establish an even closer partnership with Beckhoff – both in terms of the broad automation portfolio and the comprehensive global Beckhoff support.