EL9227 electronic overcurrent protection terminals monitor plastic recycling machines and support Industrie 4.0 concepts

In a closed-loop society, waste has long been used as raw material for new products. In fact, it’s a philosophy that Govaerts Recycling has lived by since the 1990s. But recycling is and remains a heterogeneous material flow that can demand the utmost from recycling machines, so it’s better if overloads can be detected quickly – for example, via the current consumption. The company, based in Alken, Belgium, has relied on Beckhoff measurement technology and expertise for years, most notably with the EL9227 electronic overcurrent protection terminals.

Govaerts Recycling started in 1995 with a great ambition to make more out of less. “Working in a gravel pit in the past forced us to face the fact that the land was being exploited,” explains Eddy Govaerts, who runs the company together with his sister: “Our goal was to deal with raw materials in a more sustainable way, and plastic waste seemed like the perfect starting point because that’s what we were getting paid for at the time.”

Recycling 315 million plastic bottles

Recycling of the first plastic waste began in 1997. Today, everything from planks, posts, decking and fences to furniture and playground equipment made in Alken, Belgium, can be found all over the world. These are all tested and certified by reputable bodies and the plastic products are 100% recyclable themselves. The company now works with seven machines, which transformed over 315 million plastic bottles into new products in 2021, and two additional plants are currently being planned to cope with further growth. All equipment is designed and built in-house by Eddy Govaerts and his team to ensure they retain complete control over the production process. “We want to make sure that everything we produce is of the highest quality, which means we not only have to check what goes in, but also control and understand exactly what goes on inside,” Eddy Govaerts outlines his philosophy.

Relying on people and technology

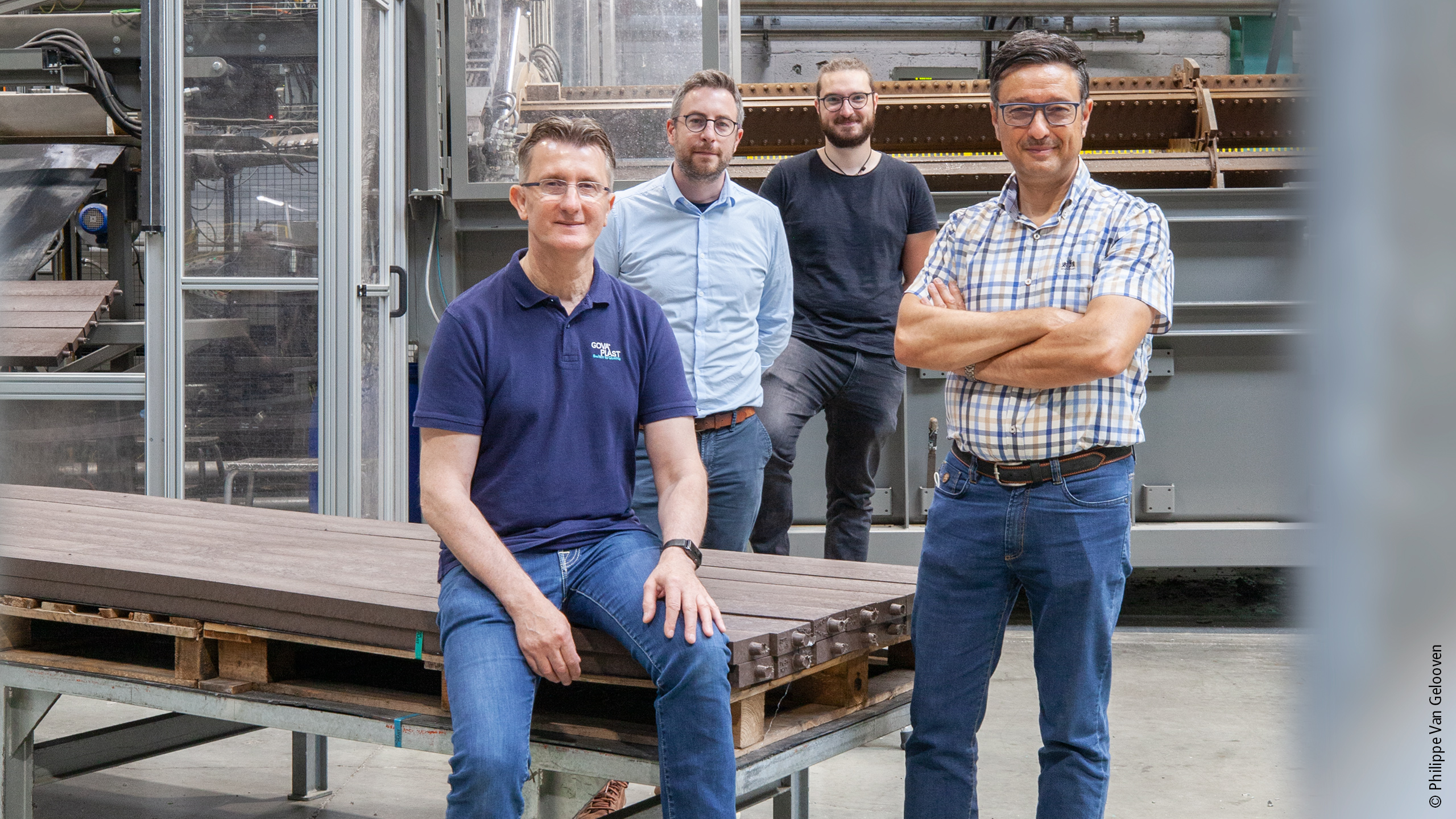

One advantage of the Govaerts plants is that the entire production process from grinding the plastic granulate to the final product takes place in a single step. This means the plastic goes through one less heating and cooling cycle than previous methods, which is a real bonus that maximizes quality and saves energy. An equally important consideration is reliable operation around the clock, which is why Govaerts Recycling has been relying on the expertise and technologies of Beckhoff for machine automation and optimization for years. As Eddy Govearts explains, “Technology is always linked to people, because the more complex it becomes, the more support you need. Beckhoff Support Engineer Philippe Hénin is our main point of contact and understands exactly what we are doing. He also listens to our needs, which means he is ideally placed to offer proactive solutions. Now that’s something that really sets Beckhoff apart.”

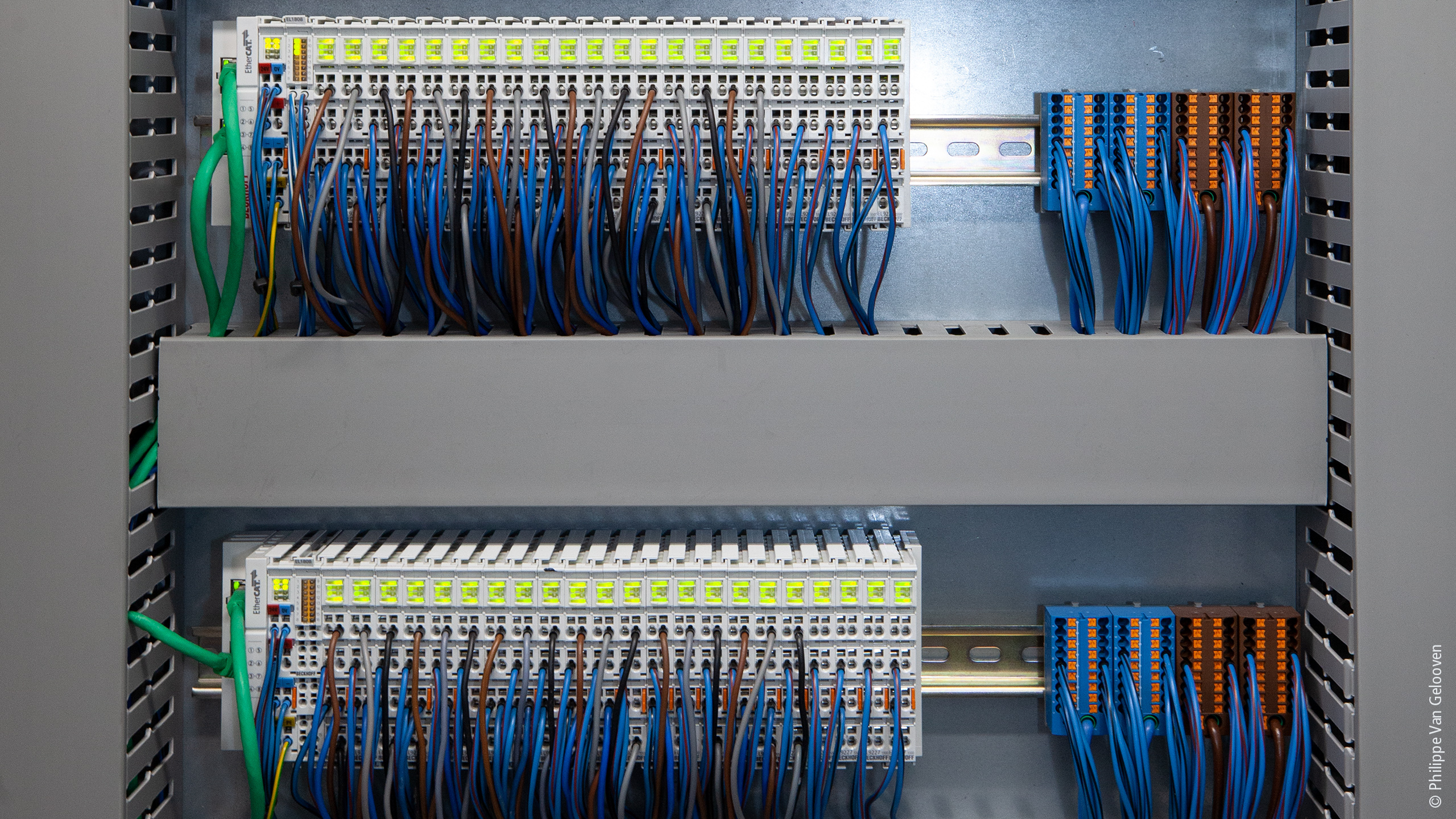

A prime example of the ongoing optimization of the machines can be found in the EL9227 electronic overcurrent protection terminals. “The step toward Industrie 4.0 is huge for us when it comes to further improving the reliability of our machines,” explains Wouter Thieren of Govaerts Recycling, who has been working on this issue for four years. “The more data we collect, the better analyses we can perform. This not only avoids problems, but it also achieves a consistently higher level of quality.” For him, the EL9227 EtherCAT Terminals are a perfect fit for the Industrie 4.0 concept. “We work with a decentralized distribution of DC circuits, and by adding two terminals to each I/O segment, we can provide electronic overcurrent protection to the respective machine sections.”

The overcurrent protection terminals also speak volumes about what is happening in the machine. As Wouter Thieren explains, “We control how much current the electronic coupling module and the power supply unit require at the input and output. And, if there’s a fault, we know exactly where it’s occurring and can switch the terminals on and off remotely or via the system visualization on our HMI.”

Comprehensive diagnostics and easy integration

In the case of the EL9227 overcurrent protection terminals, Wouter Thieren relies on the version with advanced functions because of the numerous diagnostic options available: “With these EL9227s, we can perform condition monitoring for the entire 24 V DC circuit.” If the current consumption changes, the machine operator can specifically target their search for the cause. “This all demonstrates that we are taking another step towards predictive maintenance,” says Wouter Thieren. The strength of the EtherCAT Terminals lies in the hardware’s combination with software and, of course, support: “With TwinCAT, Beckhoff has the right software to harness the full potential of the hardware. What’s more, Beckhoff facilitates system integration because it is virtually automatic.” For example, the messages from the current terminals can also be easily integrated into the machine’s HMI. “Our operators can then see an anomaly or fault immediately and don’t have to go to the control cabinet to isolate the fault based on the LEDs,” explains Wouter Thieren.

There are now so many electronics in the Govaerts machines that fast and selective protection is essential, which means thermal fuses are no longer adequate. In comparison, the EL9227 electronic overcurrent protection terminals already output a warning signal at the first sign of an anomaly, and this diagnostic alone helps to avoid a whole host of problems. “With this in mind, our DC circuits are perfectly fused and protected,” emphasizes Wouter Thieren. Not only that, but they also comply with the requirements of DIN EN 60204-IEC, which states that, as of 2020, 24 V DC circuits also have to be tested. With the EL9227 EtherCAT Terminals, Govaerts Recycling meets the requirements of the standard and also benefits from an intelligent monitoring solution that can be reset electronically.