XTS linear transport system in the pharmaceutical industry

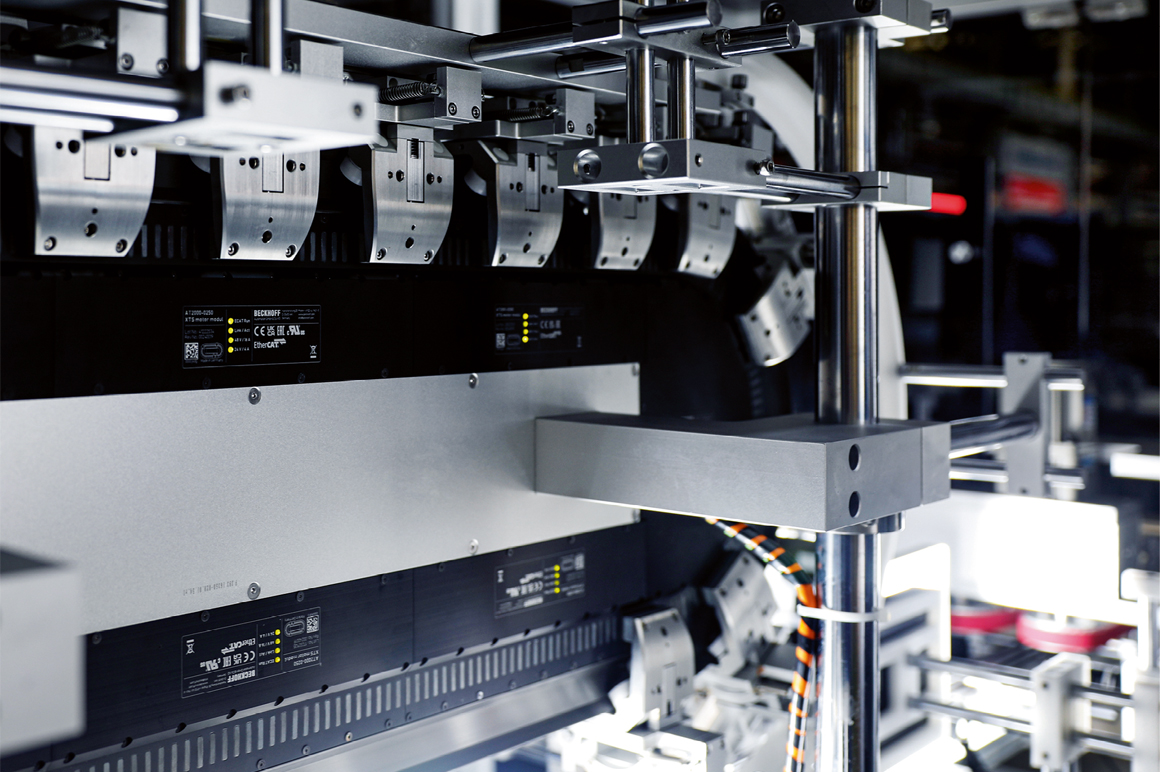

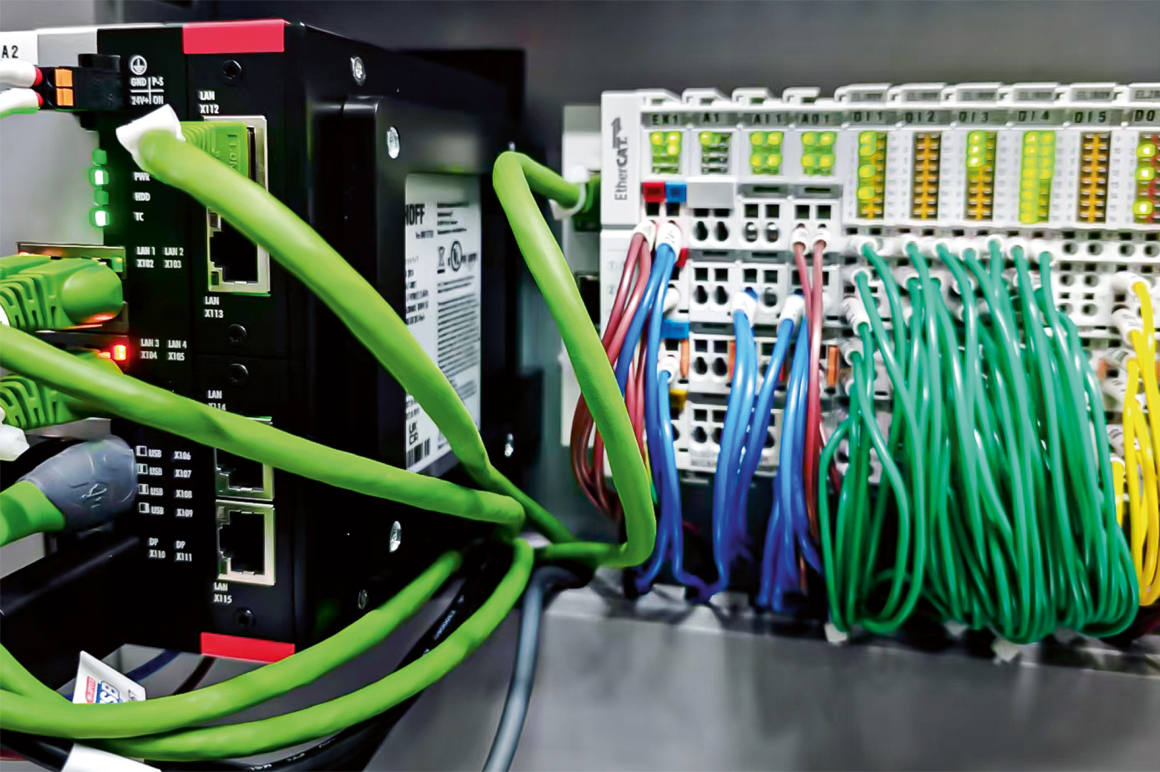

Headquartered in Zibo, Shandong Province, Shinva Medical Instrument Co., Ltd. (Shinva Medical) is a leading medical device manufacturer with many years of experience that specializes in four major business segments: medical devices, pharmaceutical equipment, medical services, and medical e-commerce. The company has continuously invested in new technologies – for example, deploying the XTS linear transport system from Beckhoff in several pieces of pharmaceutical testing and inspection equipment.

In particular, Shinva Medical has built a state-of-the-art pharmaceutical equipment platform based on four core segments: sterile preparation, solid preparation, traditional Chinese medicine preparation, and biopharmaceuticals. These key pharmaceutical production lines have a direct influence on the quality of drug manufacturing, so the associated testing equipment is a crucial aspect of Shinva Medical’s technological innovation. In its quest to achieve the highest possible quality and efficiency, Shinva Medical has been supported since 2016 by Beckhoff China, as illustrated by the use of XTS in the area of production control.

Inspection speed doubled and machine length halved

With the increasing demand for higher production capacity from pharmaceutical manufacturers, Shinva Medical needs to provide ever more efficient equipment. According to the experts, the performance of the transport system is crucial to the efficiency of the entire production line. Although conventional product transport via conveyor belts has so far been able to meet production requirements to a certain extent, these systems have a number of disadvantages. For example, their positioning accuracy is greatly affected by installation factors and they are limited by fixed production cycles, resulting in slow inspection speeds and reduced efficiency. Shinva Medical remedied this situation with the XTS transport system, an innovative automation technology that is characterized by the fact that it can be individually adapted to the application in question. As a result – according to the experts at Shinva Medical – the layout of workstations has been revolutionized thanks to a high degree of flexibility, minimized space requirements, optimized production cycles, and significantly improved testing efficiency.

During the design process of a vacuum decay leak detection machine, Shinva Medical initially used the XTS Viewer of TwinCAT 3 XTS Extension to perform comprehensive simulations of the process cycle times. By simulating operation under various parameters, it was possible to clearly visualize the machine’s operating state, which made it easier to define the XTS transport line in terms of the system's track length and number of movers. According to Wang Dangqi, electrical supervisor at Shinva Medical, this optimization strategy not only ensures reliable operation of the machine, but also improves the efficiency of the workstation with the longest cycle time. While the inspection station is in operation, the use of XTS enables the conveyor line to maintain exceptionally high-speed and reliable performance, as well as allowing bottles to be loaded and unloaded at other stations while this inspection is still in progress. “With this machine design, the inspection speed has been increased from 30 to 60 test specimens per minute, doubling production efficiency. Furthermore, the machine length has been reduced from 4 to 2 m, significantly decreasing the footprint of the machine and lowering the investment cost per unit area of the factory.”

Optimized quality with optical inspection

According to the experts at Shinva Medical, this automatic pharmaceutical inspection machine is indispensable when it comes to conducting quality inspections on liquid-filled pharmaceutical bottles such as ampoules using optical, mechanical, and image processing technologies. To ensure the purity and safety of the pharmaceuticals, it rapidly and accurately detects imperfections in pharmaceuticals, including cracks, color unevenness, foreign materials, etc. When designing the optical inspection machine, Shinva Medical took full advantage of the flexibility of XTS and innovatively harnessed the option to control each mover individually to simulate the manual shaking of bottles. This causes the bottles to vibrate slightly during transportation, allowing any flaws and defects on the bottle surface to be detected more reliably. “By simulating the effect of manual bottle shaking, our optical inspection machine can capture more detailed information, improving the accuracy and reliability of the visual inspection. This not only optimizes inspection quality to ensure high product quality, but also reduces the labor intensity of manual inspection, thereby increasing production efficiency,” explains Wang Dangqi.

By collaborating on innovative projects, such as the implementation of the XTS linear transport system, Beckhoff China has successfully met Shinva Medical’s stringent requirements for automation and control technology in the manufacture of medical devices. From the provision of complete control solutions to high product quality and from comprehensive technical service to a strong international brand image, Shinva Medical confirms it has benefited in many ways from its cooperation with Beckhoff – and has been able to strengthen its competitiveness in national and international markets as a result.