High-performance path interpolation system promotes efficient and precise use of robots

PMA Pacific is committed to replacing traditional manual grinding processes in the Chinese sheet metal industry with cutting-edge solutions. The company’s vision involves promoting environmentally-friendly and efficient automated polishing solutions and providing more customized sheet metal grinding solutions. This goal lent itself to abrasive belt grinding machines from Peitzmeier Maschinenbau, which incorporate the entire Beckhoff range of PC and EtherCAT-based control and drive technology – especially TwinCAT 3 NC I software.

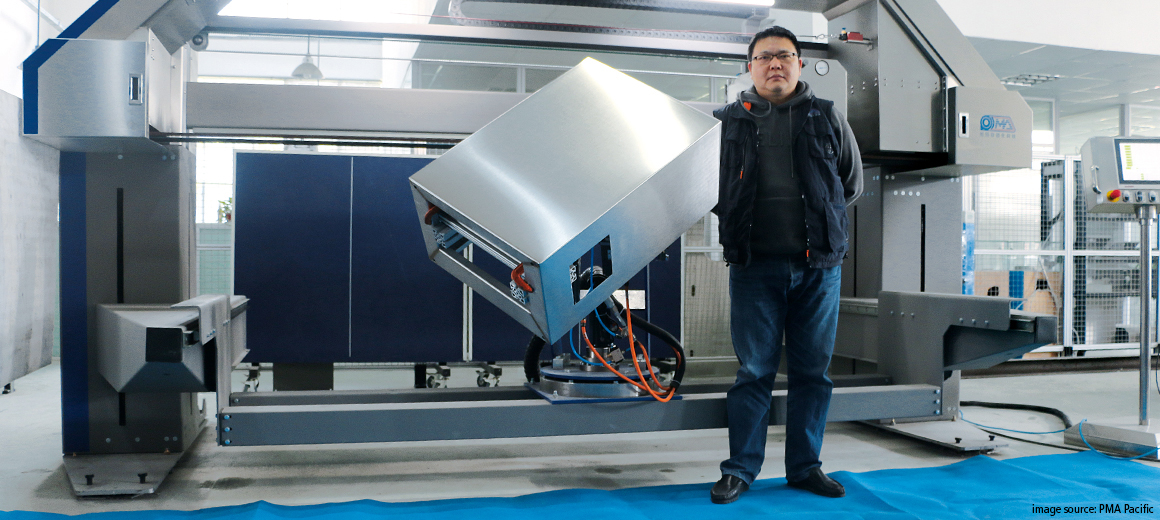

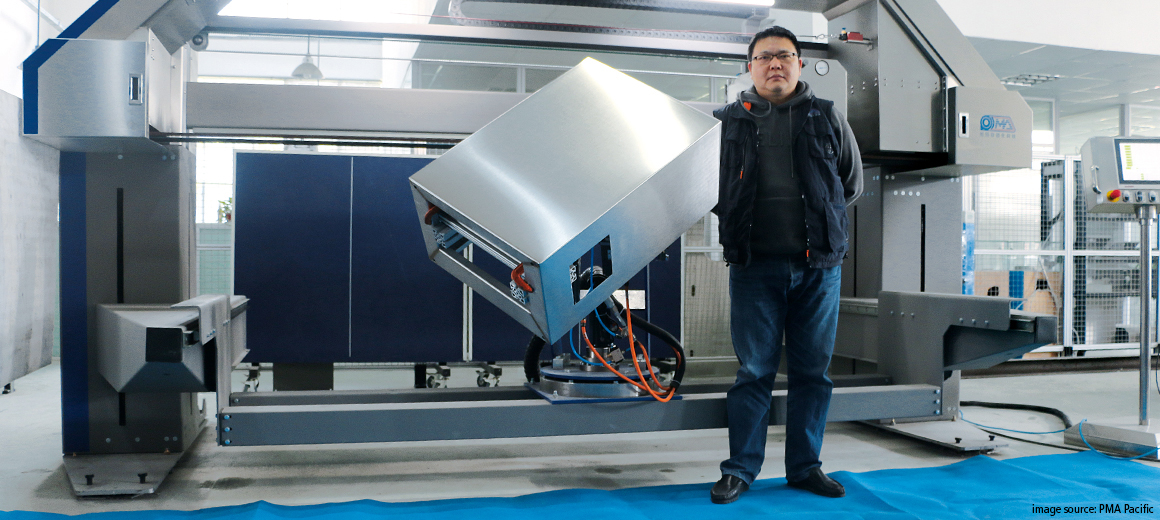

PMA Pacific Machinery Company Limited (PMA Pacific) was founded in August 2015 and is located in the modern China-Singapore Suzhou Industrial Park. The company is the production center, service base and sales headquarters of abrasive belt grinding machines from German company Peitzmeier Maschinenbau GmbH in the Asia-Pacific region. The product range covers standard machines and customized solutions for processing workpieces such as cases and cabinets, covers for kitchenware and parts for food and drug machinery or packaging machines.

Especially in the food and pharmaceutical industries, a finely polished, high-quality surface also means a lower risk of contamination. Manual grinding is highly labor-intensive in this respect and can also pose health risks due to the large amounts of metallic dust generated. Consistently high grinding quality and efficient grinding processes are thus only achievable by increasing the level of automation – even with smaller batches down to lot size 1. The new generation of polishing and grinding machines is ideal for this purpose. Based on PC Control and TwinCAT as well as robotic technology, they enable automated grinding, reduce labor costs and improve grinding efficiency.

Hardware architecture for high precision and dynamics

PMA Pacific already uses PC-based control in its conventional machines. Now TwinCAT automation software will also be used for the programming, teaching and operation of newly developed robot-based polishing and grinding machines. PMA Pacific General Manager Yue Yang Zhu explains: "PC-based control technology from Beckhoff is flexible and enables convenient programming of even complex algorithms. TwinCAT offers an extensive range of functions to meet the general requirements of polishing and grinding machines. PC-based control and TwinCAT especially offer excellent real-time performance and can therefore also achieve complex motion control. The comprehensive Beckhoff product portfolio includes all the required automation components, from EtherCAT I/Os to servo drive technology through to complete control systems." The automation system of the new abrasive belt grinding machines consists of a high-performance CX2020 Embedded PC and a CP2915 multi-touch Control Panel, as well as the powerful AX8000 multi-axis servo system and AM8000 servomotors. In addition, TwinSAFE components have been integrated into the complete system to ensure optimum machine safety.

The X-axis and Y-axis of the integrated robot adopt the gantry axis structure. The ABC axes each have a servomotor plus the Z-axis of a grinding head to construct a straight line and rotating motion with six degrees of freedom. The modular, EtherCAT-based AX8000 compact drive combines high-performance FPGA technology with multi-core ARM processors. FPGA-based control algorithms with multi-channel current control technology enable sampling and response times of less than 1 µs to regulate current and speed control cycle times of as low as 16 µs – depending on the configured switching frequency. The requirements of a wide motor regulation range and highly dynamic robot actions can therefore be fulfilled optimally.

According to Yue Yang Zhu, when combined with the EtherCAT-based I/O system, this integrated solution supplies the necessary data transmission speed and flexibility to realize PMA Pacific's powerful and modular machine design and manufacturing concept. Moreover, with TwinSAFE, the required safety functions can be implemented as an integral part of the control solution: for example, if the emergency stop key is pressed or if the belt breaks, the drive is stopped as quickly as possible via a ramp-down function before the main drive motor is switched to operate with no torque. Optical sensors protect the setup mode, with TwinSAFE reducing the feed rate to two meters per minute if safety measures are activated.

Software platform for flexible grinding processes

In conventional grinding machines, only the grinding head and direction of X and Y can be controlled automatically, which means that only flat surfaces are ground. Manual intervention is necessary for curved surfaces or curved surface transition between two flat surfaces. In comparison, not only can the new robot-based polishing and grinding machines automatically grind flat surfaces, they can also grind curved workpieces. The appropriate movement with six degrees of freedom simply involves tracing the contours of workpieces using a handwheel, ‘teaching’ the start position and entering the desired feed rate. Eight surfaces can be defined at present for each workpiece, with up to 32 transition points and eight grinding processes possible in each case.

The system uses TwinCAT 3 NC I software to conveniently realize the robot's path movements by teaching points on the touch screen. After defining the grinding processes, the PMA Pacific system loads sheet metal parts automatically, grinds the flat, arc and irregular surfaces using path interpolation, and finally unloads the workpieces. TwinCAT 3 NC I can realize movements of three-axis interpolation and five auxiliary axes for this purpose. Its abundant G-code instructions and transitions guarantee that the robots pass through teaching points precisely and engineering efficiency is improved.

Application advantages of PC-based control

Among the core advantages of PC-based control from PMA Pacific's perspective are the ability to modularize the control technology and build an optimized control system. Another important factor is the programming speed and ease, and the flexibility of the control system when processing different workpiece shapes. Yue Yang Zhu sums up: "The powerful TwinCAT software offers a high degree of application flexibility. In the future, there will be a series of new grinding processes, such as the import of graphic G-code, pick-and-place robotics and synchronization of drive belts. And only Beckhoff’s control technology can fully meet all of these requirements. PC-based control technology provides the great advantage for us that we can realize the use of robots on polishing machines by integrating motion control, robotic algorithms and visualization. The universal and integrated control architecture simplifies engineering and reduces the total cost of the solution."

Main features of the machine

Some of the main features of the full-servo and flexible twin belt grinding machine OG-Twin-3107-AF are multi-axis cooperative action (up to 10 servo axes), 50 kg loading capacity of the manipulator, 5 integrated servo axes for rotating of special workpiece (as flexible as a robot), cooperative action with auto-tool for easy grinding workpiece of intricately shaped, interpolation control of each axis based on TwinCAT 3 and robot algorithms. The machine is designed for fully automatic grinding and polishing. It is suitable for not only mass production mode such as kitchenware and cabinet manufacturing, but also suitable for multi-variety production mode because of quick change for different tooling.