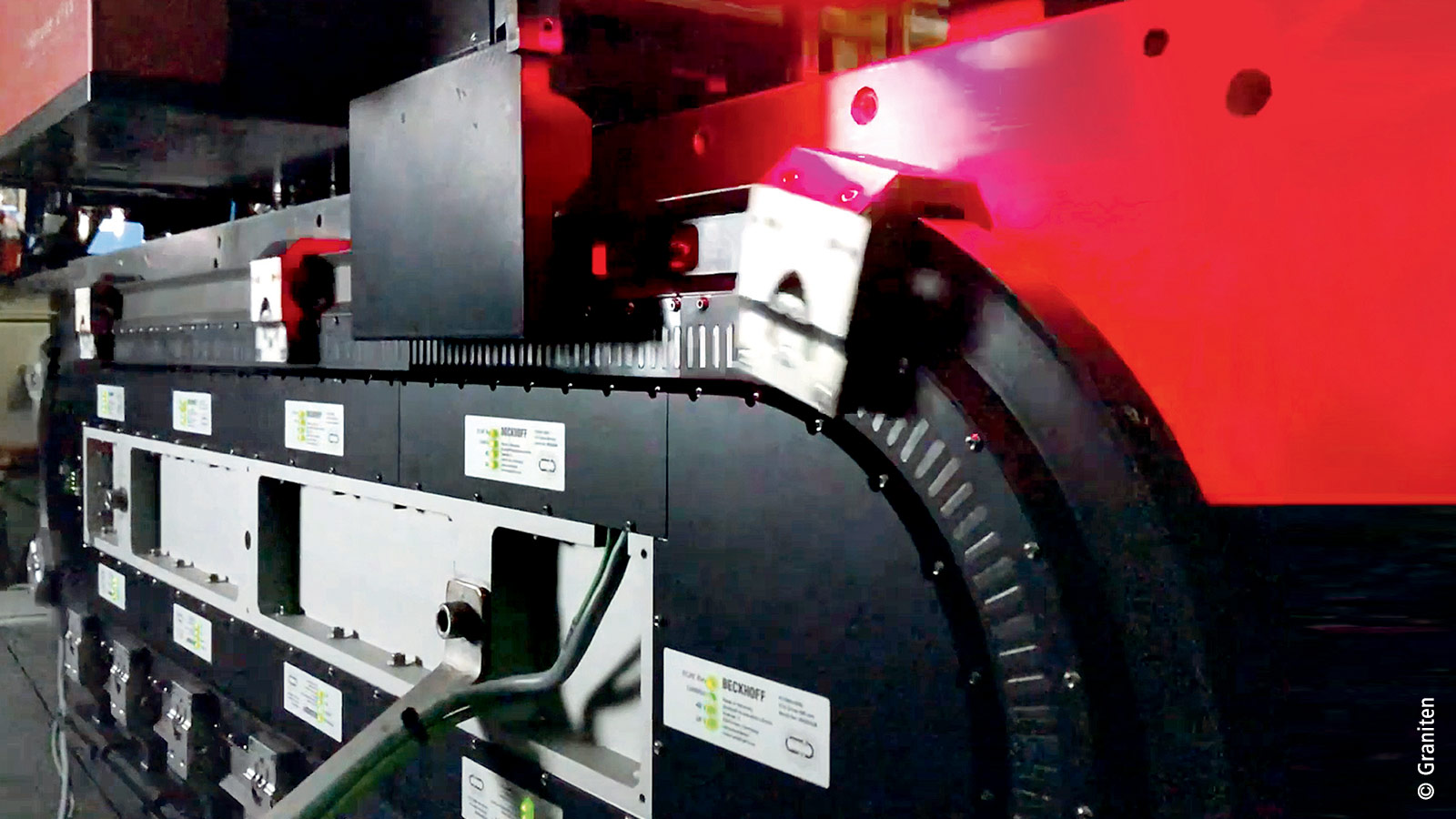

The eXtended Transport System at the core of a digital pad printing machine for the pharma industry

Maximum flexibility, virtually no changeover times and reduced maintenance and space requirements – this is what the Swedish Graniten Group has achieved with a new digital pad printing machine. This is the world's first gravure printing system of its kind to be equipped with the XTS intelligent transport system from Beckhoff as the core element. In this way it is able to meet the high requirements of the pharmaceutical industry and can, among other things, convert an uneven product feed into an even product outfeed.

Graniten was established in the early 1990s by engineers as a technology-oriented company and encompasses today the three business areas Machinery, Engineering and Service & Support. According to Graniten, the global pharmaceutical industry as a target industry is increasingly relying on up to 100% automated processes in production as well as printing and packaging. In addition, according to Graniten, exceptionally high speeds, efficiency, hygiene, control, traceability, low maintenance and minimum footprints are required – combined with extreme flexibility. Graniten has solved all of these challenges with the introduction of the XTS-based digital pad printing machine.

“Over the last few years, we have developed innovative machines for carton and case packaging, palletizing and leakage detection for BFS (Blow, Fill, Seal) systems. We are now introducing fast, flexible digital printing, closing a gap in the entire process. This will make it easier for the pharmaceutical industry to optimize the entire workflow in an intelligent way,” explains Fredrik Sollenby, Managing Director as well as Vice President Sales and Marketing at Graniten.

Intelligent transport system for greater flexibility

Digital printing is already a well-known process in the pharmaceutical industry. With the XTS intelligent transport system as a core element, however, the new Digital Pad Printer is now expanding the existing possibilities, because the individual movers for the product transport can be controlled individually and therefore driven at different speeds. In this way, a buffer function can be implemented simply on a software basis in order to allow more time for the UV ink-curing process, for example, which takes longer than other work steps. In addition, products detected as being defective can be efficiently removed from the process flow.

Fredrik Sollenby says: “What clearly distinguishes the Digital Pad Printer from conventional systems is the XTS transport system, meaning that even with an irregular product infeed and individual handling in each work step, a continuous workflow can be achieved. As a result, the product outfeed can be arranged in an even manner and synchronized with downstream equipment in a continuous product flow, which is ideal for feeding flow wrapping machines, e.g. This solution meets the pharmaceutical industry's requirements for a fully automatic process that is at the same time optimized for each individual subprocess.”

There are further advantages for the end user, as Fredrik Sollenby explains: “The machine users can reduce the conversion time between different jobs to almost zero as well as reducing the time required for service and maintenance, because XTS replaces conventional mechanical engineering to a great extent by software functions. Not only that, the machine reduces the CO2 footprint. Digital printing directly on a plastic container or paper packaging is faster and far more sustainable than conventional pad printing on labels. And last but not least, the machine is considerably smaller than previous systems due to XTS.”

Innovative solution to complex problems

Graniten has been developing machines with XTS for the pharmaceutical industry since 2014. More than 15 machines have already been delivered; several new orders are currently in progress. According to Frederik Sollenby, the Beckhoff technology supports Graniten's philosophy in an ideal way: “We develop intelligent turnkey machine solutions exactly according to specific customer requirements. We have been working with Beckhoff for six years and value their innovative technical approach to solving complex industrial problems as well as their comprehensive support.”