The Module Type Package (MTP) is a solution for modularizing systems in the process industry. Beckhoff has integrated the MTP concept into TwinCAT as a software solution. In this video, we discuss its current status, innovations, and the resulting benefits.

More about this video

Module Type Package

TwinCAT MTP integrates the Module Type Package concept into the engineering environment and enables efficient development of modular plants.

TE8400 | TwinCAT 3 MTP Engineering

An MTP (Module Type Package) is a communication interface between a higher-level control system (e.g. process control system) and a modular plant. The MTP describes the interface of visualization, provided services and other features of a module, so that a simple orchestration of the modules to form a complete plant can be done easily and quickly in the higher-level control system.

TF8400 | TwinCAT 3 MTP Runtime

An MTP (Module Type Package) is a communication interface between a higher-level control system (e.g. process control system) and a modular plant. The MTP describes the interface of visualization, provided services and other features of a module, so that a simple orchestration of the modules to form a complete plant can be done easily and quickly in the higher-level control system.

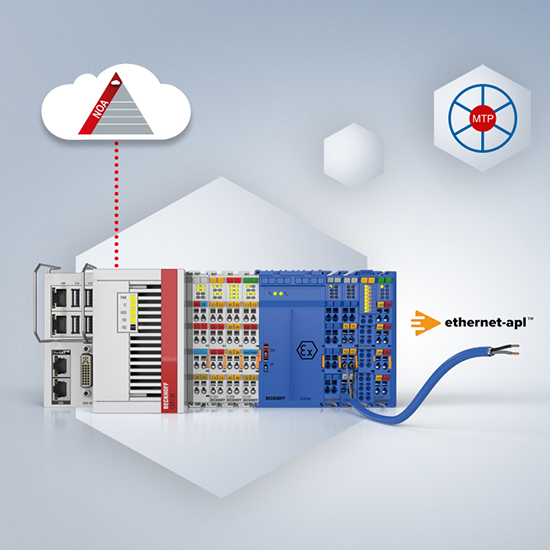

Digitalization for the process industry

Implement future-proof automation of process plants with Ethernet-APL, NAMUR Open Architecture, and MTP.