Our control technology has been used in the packaging industry for over 20 years. Packaging machinery around the globe is automated with Beckhoff in a variety of industries, including cosmetics, pharma, medical technology, and food and beverages . A large number of references from a wide range of packaging application sectors confirm that our control solution is highly effective. Exciting applications show you how PC-based control optimizes packaging processes and machinery across the board.

Current applications at a glance

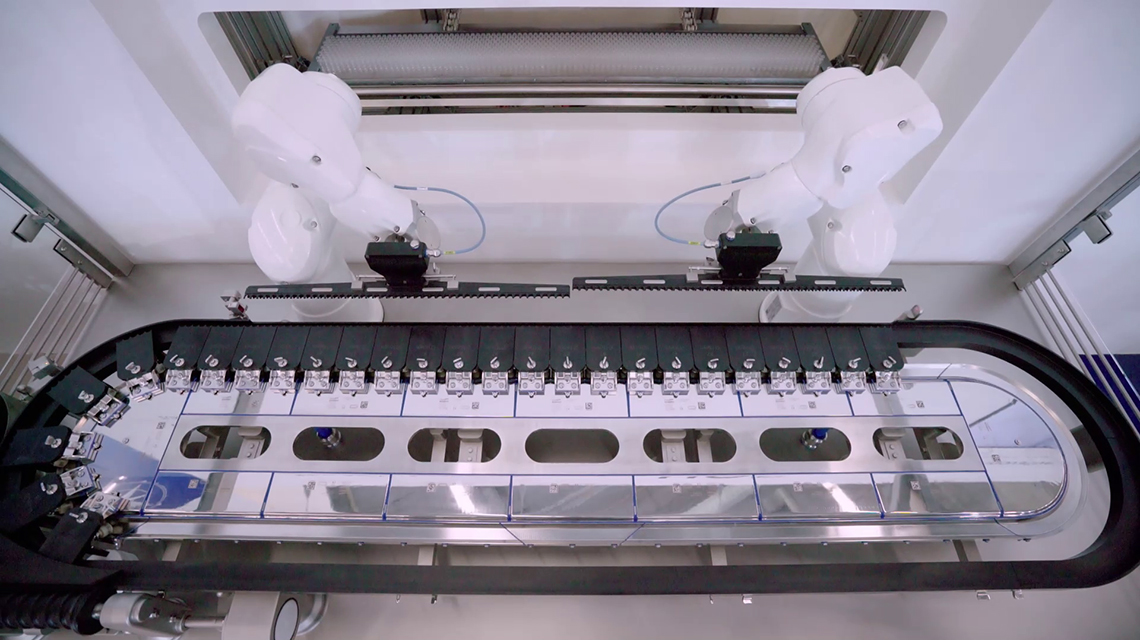

Integration of an L-shaped XTS system for optimum use of existing production spaces

As a specialist for packaging lines, Schubert Packaging Systems relies on the XTS linear transport system for a new solution for packaging vials and ampoules. An L-shaped geometry was particularly helpful here to ensure efficient use of the available hall space. In addition, XTS simulation was used at an early stage of the project so that the key parameters could be checked and optimized.

PC-based motion control on a labeling machine for the pharmaceutical industry

For more than 50 years, Bausch+Ströbel SE + Co. KG, headquartered in Ilshofen, Germany, has been developing packaging and production systems for the pharmaceutical and related industries. The company’s goal is to offer the best technical and economical solutions for the challenges of the modern market. The new ESA1025 labeling machine for various pharmaceutical containers shows exactly how this is implemented with PC-based control from Beckhoff as the central motion controller.

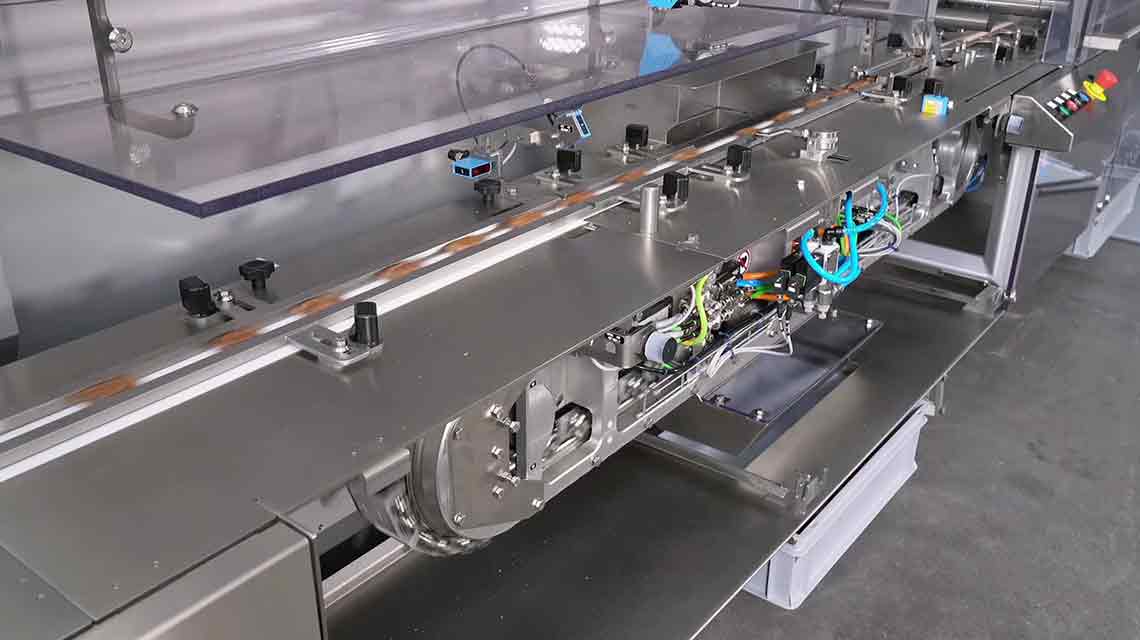

HOF Sonderanlagenbau: XTS Hygienic for the transport of pharmaceutical products

The XTS Hygienic is the central element of a new system design for the transport of pharmaceutical products at HOF Sonderanlagenbau. The stainless steel version of the intelligent XTS transport system meets all industry standards. It is designed for use in an isolator and can be cleaned with hydrogen peroxide. In addition, XTS enables particularly gentle product transport, which has reduced glass-to-glass contact.

XTS in use for high-performance packaging systems for confectionery products

Syntegon Technology in Beringen is a leading supplier of fully automated packaging systems for confectionery manufacturers around the world. The global confectionery industry is subject to many, sometimes rapidly changing trends. For manufacturers, this means producing many, different products that need to be packed in a wide variety of packages and pack sizes. "The intelligent transport system XTS gives Syntegon the flexibility to optimally solve every task with innovative ideas. In the meantime, we have been able to install around 100 packaging systems with XTS in the market," explains Kurt Gleichauf, Head of Technology & Development at Syntegon Packaging Systems AG in Beringen.

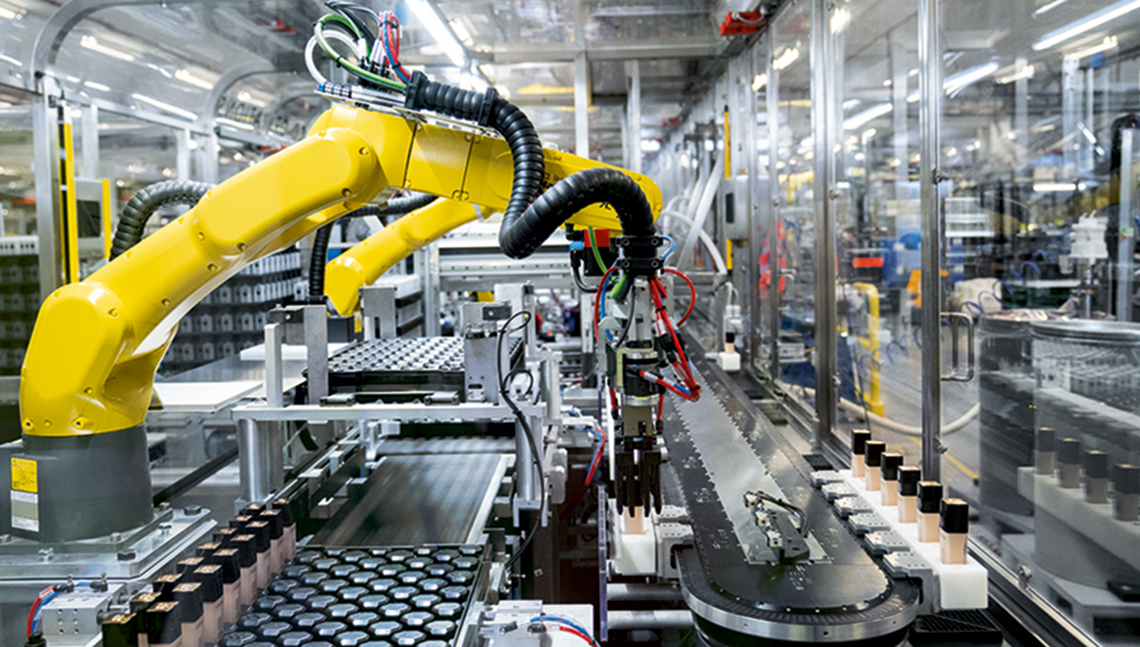

Realignment of the production: XTS as the core element of a new solution

L’Oréal is a leading cosmetics manufacturer and has set the strategic goal of making its production operations more agile. In order to achieve this, three production lines have already been equipped with the flexible XTS transport system. The XTS is the core element of the production lines and combines the functionality of five previously separate machines. The same line can now produce lot sizes ranging from a few hundred to millions of pieces as well as seven different format types with only 40 instead of 300 transport containers.