TwinCAT MC3: Next-generation motion control

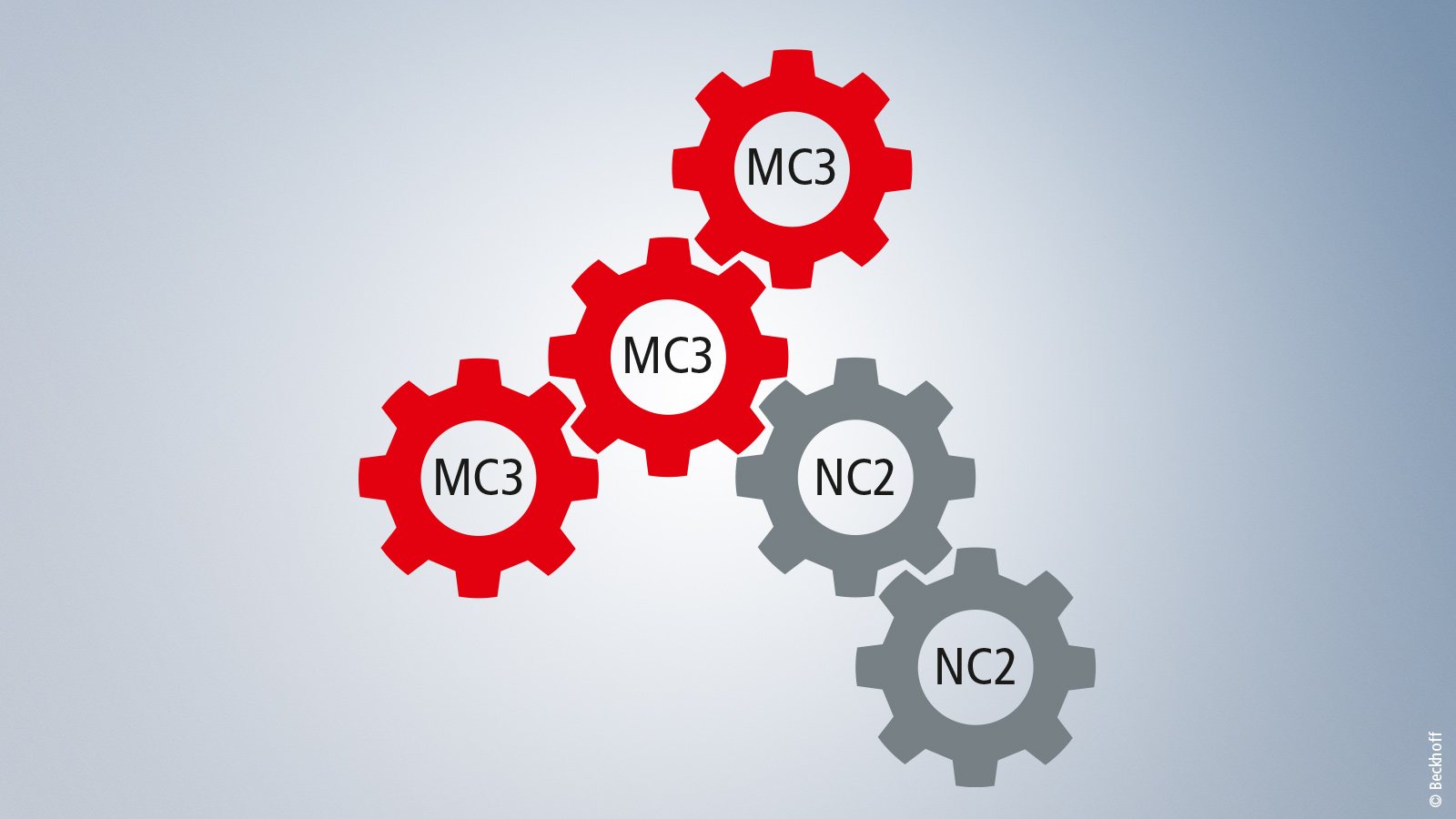

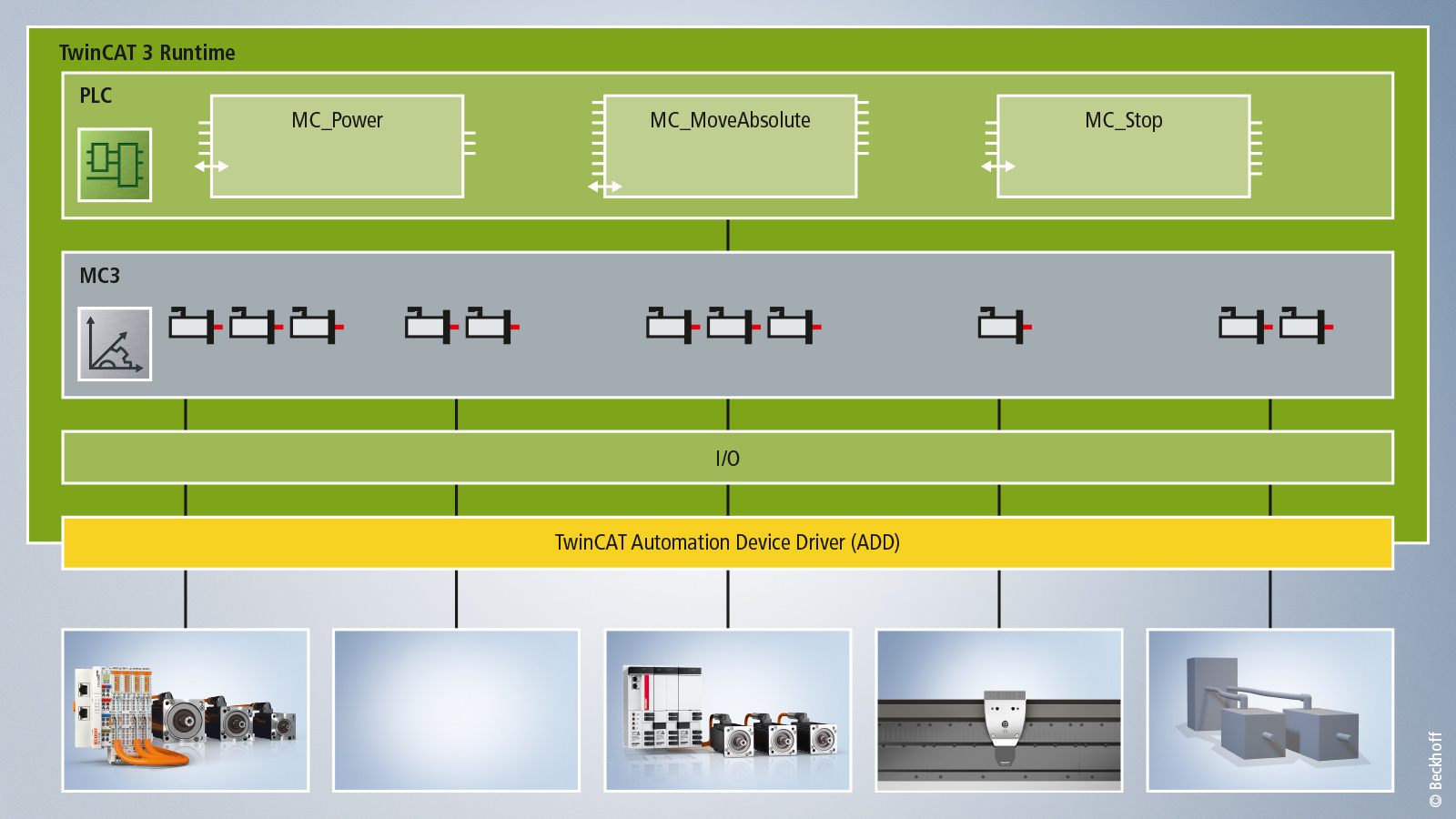

TwinCAT MC3 is an all-new generation of motion control, characterized by comprehensive multi-core and multi-task support. Based on a modular architecture, it enables the seamless integration of axes already implemented with the proven TwinCAT NC2 solution while also facilitating the straightforward integration of future motion requirements.

Motion control has been an essential component of the automation platform since TwinCAT first launched in 1996. The long-standing success of the TwinCAT NC2 solution is testament to the well thought-out and practical concept behind its inception. With axes abstracted into axis objects, users can simulate and program axes independently of hardware. What’s more, they can also access a wide array of functionalities ranging from basic single-axis movements through to complex axis couplings and subsequent path planning, catering to diverse application needs.

Complete system integration and advanced architecture

The key features of the previous motion control solution from Beckhoff are also present in TwinCAT MC3, allowing for seamless integration into the TwinCAT system and facilitating axis abstraction. TwinCAT MC3 also offers a host of additional advantages through a new and modular architecture. These notably include comprehensive multi-core and multi-task support with the possibility of synchronized movements across all processor cores in use, and the fact that the previous restriction on the number of axes no longer applies.

The seamless integration of TwinCAT MC3 into the TwinCAT system means that the motion control solution can not only be operated in parallel with the other TwinCAT functions in one system, but can also interact with the other TwinCAT functions. The highlights are as follows:

- TwinCAT MC3 can be operated in parallel with the previous NC2 motion control solution, and MC3 axes can also be coupled with existing NC2 axes. This makes it possible to implement new machine components with TwinCAT MC3 without having to adapt existing machine components that use NC2.

- TwinCAT Drive Manager supports the commissioning of Beckhoff drive solutions and, as is typical for NC2, can also automatically create MC3 configurations and MC3 axes with standard parameters.

- TwinCAT Scope is a powerful diagnostic tool that can be used to record movements and dynamics and then analyze them manually using various toolboxes.

Scalable performance with multi-core and multi-task support

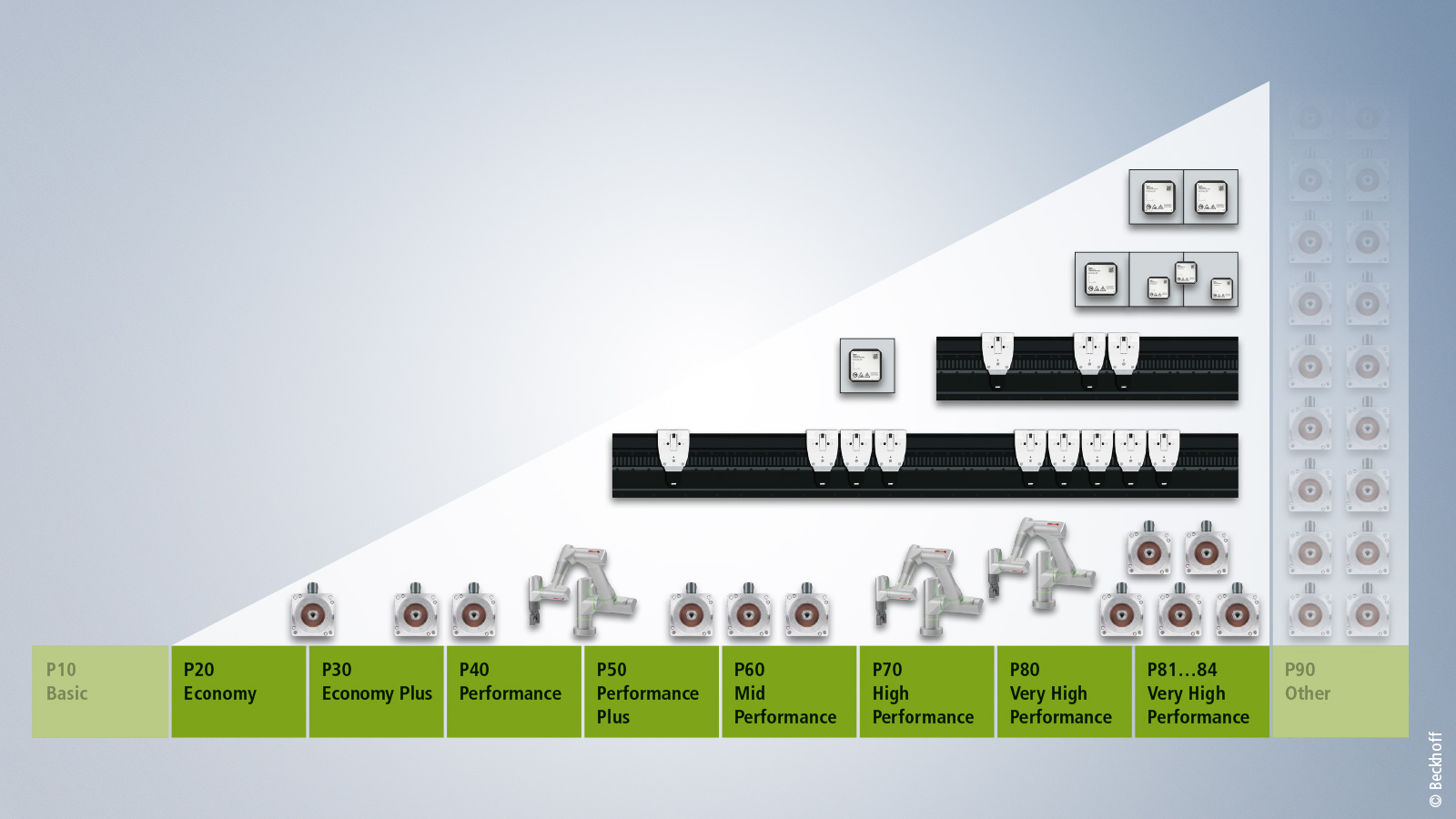

TwinCAT MC3 maximizes the utilization of the control computer’s CPU performance through its comprehensive multi-core and multi-task support. As a result, the potential number of axes and application complexity scales in alignment with the chosen TwinCAT platform level:

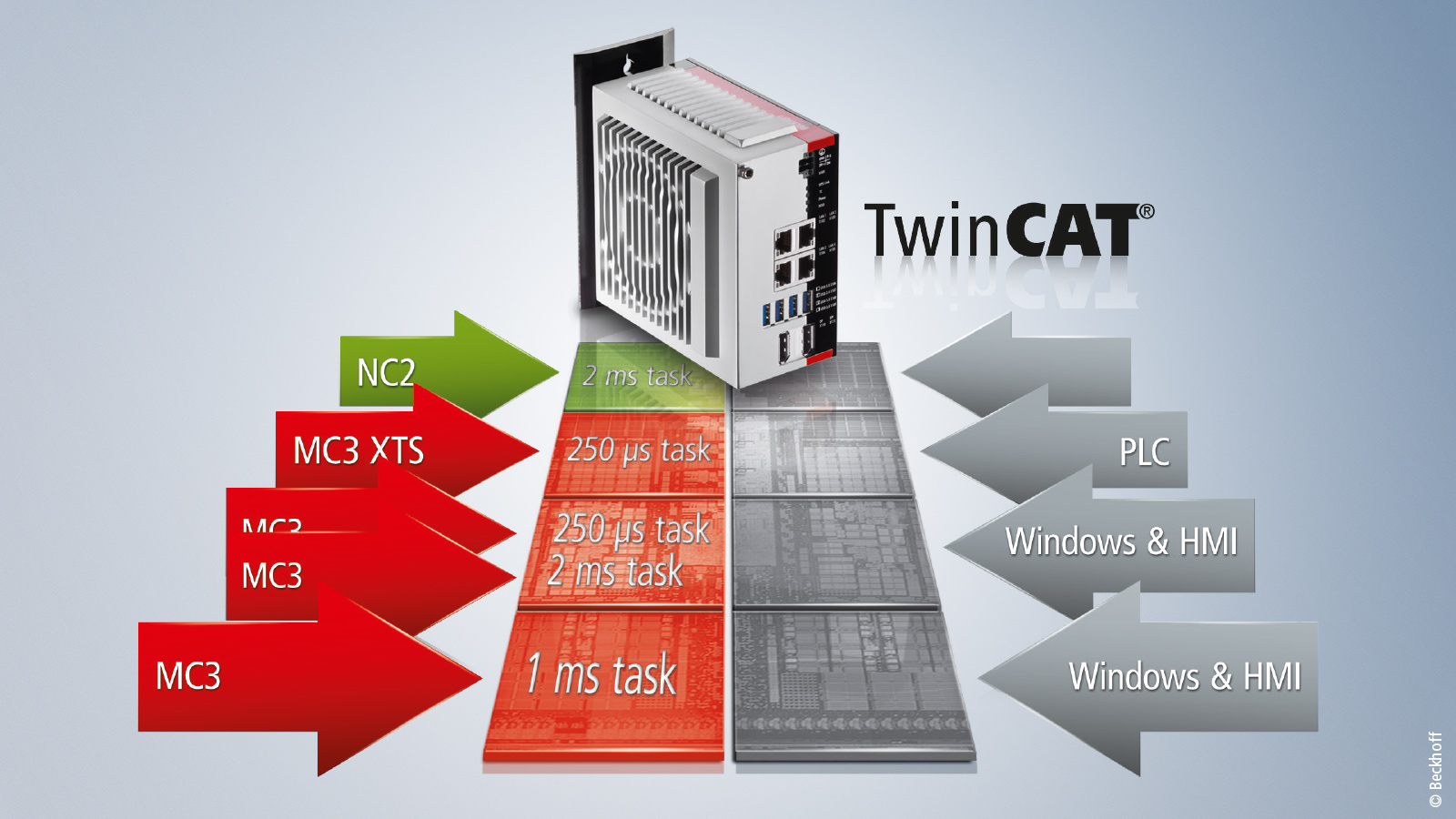

- In this context, multi-core support means that TwinCAT MC3 can be distributed to several CPU cores as required. Movements can be synchronized across all CPU cores in use.

- Multi-task support means that axes with different cycle times can be operated on a single CPU core, precisely matching the speeds and tasks of the respective axes. This facilitates optimum utilization of a CPU core, as the "fastest" axis does not necessarily dictate the clock rate for all axes. In this way, the axes of a conveyor belt with a delta picker can be operated with a cycle time of 1 ms to ensure that the workpieces are picked up quickly, while the axes for width adjustment of the conveyor belt are operated with a cycle time of 4 ms on the same CPU core

Advantages of hardware independence

As with the previous motion control solution, TwinCAT MC3 abstracts the axes into axis objects that separate the hardware from the programming process. This creates hardware independence, the advantages of which can be seen in the following features:

- Axes can be simulated, whereby a mixture of real and simulated axes is also possible within a project. Switching between the real and simulated axis can be carried out in the configuration with a single click, for both an individual axis and a group of axes. This makes it possible to program the axes without a connection to the hardware and reduces the commissioning time on the real machine.

- TwinCAT is an open control platform that supports the EtherCAT high-performance communication system as well as all other common fieldbus systems.

- A wide variety of drive systems, such as servo, stepper, and DC motors, as well as the XTS product transport system, can be equally abstracted into axis objects and therefore be programmed uniformly. Programming is facilitated by the TwinCAT Tc3_Mc3 library, which offers PLCopen-compliant function blocks that users may recognize from NC2.

- With TwinCAT MC3, hydraulic axes are now also supported and fully integrated. General programming is carried out using the same PLCopen-compliant function blocks that are used for electric axes. There is also a library with supplementary function blocks for special fluid power functionalities.

Modular architecture and high functionality

TwinCAT MC3 is based on a modular architecture, which provides a future-proof foundation. Building upon this new architecture are features such as multi-core and multi-task support. This architecture will also facilitate or enable the implementation of new capabilities in the future, such as the customization of profile generators, drivers or filters to meet customer-specific requirements. TwinCAT MC3 also incorporates the familiar and proven functionalities of NC2. The first release of the next-generation motion control solution will commence with point-to-point (PTP) movements and couplings, covering a broad spectrum ranging from simple linear axis couplings to non-linear couplings in motion.