Highest level of flexibility in sterile sampling bag production with PC-based control

Canadian manufacturer Labplas specializes in the customer-specific production of sterile sampling bags and accessories in the most diverse dimensions and develops its own production machinery. In a redesign with PC-based control, Labplas has been able to increase productivity and also to integrate pick-and-place robots, which replace the manual insertion of accessories into the bags.

Labplas has grown exponentially since its founding in 1987. Based in Sainte-Julie, Quebec, the company serves customers in the food, agriculture, environmental, veterinary and pharmaceuticals industries, Labplas offers sterile sampling bags, testing wand kits and environmentally friendly biodegradable bags. Attention to demanding quality standards are crucial for manufacturers in the aseptic sampling industry. After all, sampling bags must carry sampling sponges, food items, pharmaceuticals or organic matter for testing in labs and protect against contamination.

The ability to meet individual customer needs is a unique selling point for Labplas. Therefore, the company designs, builds and implements leading-edge manufacturing technologies. With its tailor-made machine line, Labplas creates custom products ranging from 3- to 33-inch-wide bags in various material types with few changeovers. “We believe we have one of the best technological platforms in the world for these products, but we continuously improve our systems through automation to achieve even higher throughput for a larger number of products while maintaining our agility,” says Benoit Brouillette, general manager for Labplas.

Modular control technology boosts production

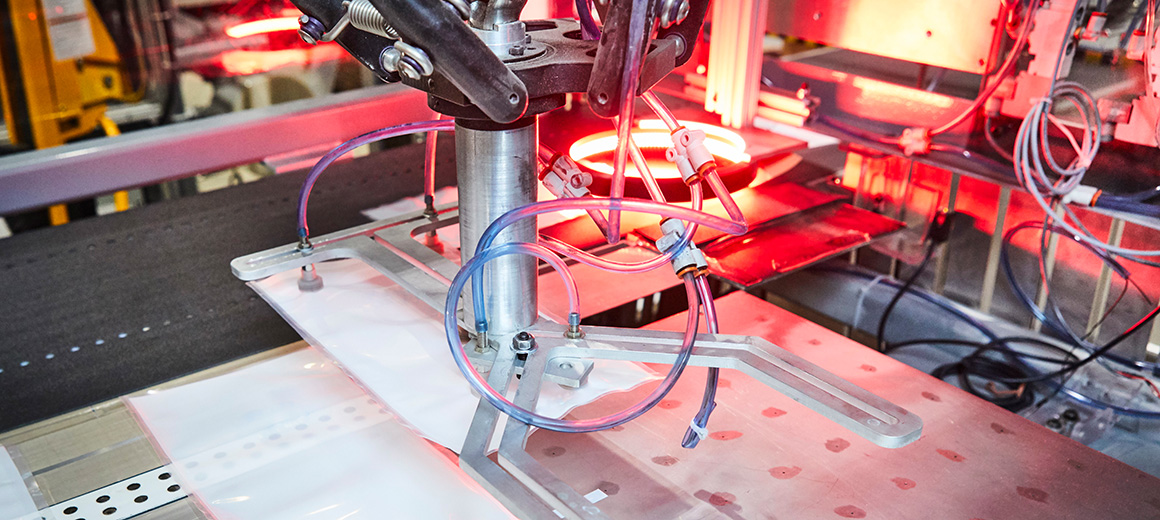

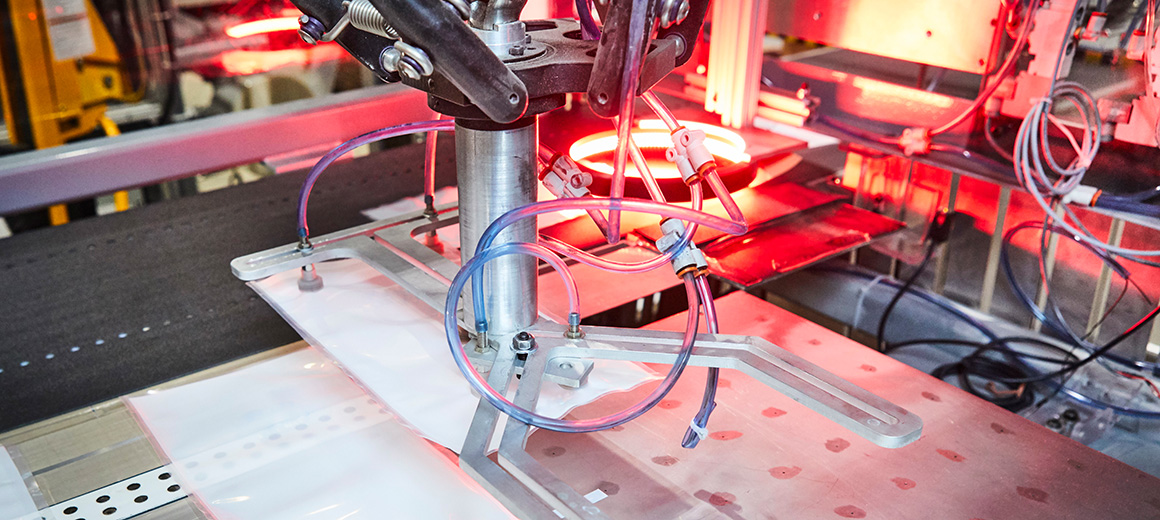

During a recent redesign of several MM series production lines, Labplas implemented additional robotics and GigE cameras to improve throughput, repeatability and quality assurance. However, the key for Labplas in any machine upgrade is carefully considering the control platform down to the component level so that they remain versatile enough to produce custom products.

Labplas wanted to upgrade its assembly technology to form sampling bags and insert the sampling accessories, such as sponges, cloths, spoons or scissors, with a robot arm instead of in a manual process as before. To achieve the design upgrade of the lines, Labplas considered different form-fill-seal partnerships and designed a new way of integrating this equipment with a six-axis delta robot.

All components needed to work together in real-time without cross-vendor communication issues, while collecting data for reporting and process improvement. The redesign was expected to increase throughput and make it easier for operators and maintenance personnel to move from one line to another. Since traditional PLCs from a previous vendor could not support the robotic and other requirements, Labplas selected Beckhoff as their new automation partner. During the implementation, Labplas R&D Department Manager Christian Fontaine and his team worked hand in hand with Beckhoff Canada applications and support engineers under the direction of Beckhoff Area Sales Manager Ted Sarazin.

Powerful drive technology boosts productivity

Motion control hardware and TwinCAT 3 automation software from Beckhoff had large impacts in the machine redesign. Labplas now uses robots across 15 of their lines, and the pick-and-place robots and other motion axes are fitted with AM8000 servomotors for dynamic applications controlled by AX5000 EtherCAT Servo Drives. They connect to the drives using One Cable Technology (OCT), which reduces wiring by combining power and feedback in a single cable. Labplas also chose to include the TwinSAFE drive card with built-in Safe Torque Off (STO) and Safe Stop 1 (SS1).

“With TwinCAT Kinematic Transformation, high-precision movement is possible even at high speeds and accelerations due to integrated dynamic pre-control. Most importantly, the powerful TwinCAT suite makes it possible not only to control the Codian robots, but also the entire machine line in real-time,” Sarazin says.

Industrial-grade hardware, scalable for all requirements

Engineers and operators interact with the MM machines via CP29xx Control Panels, which are connected via CP-Link 4, the One Cable Display Link, to the DIN rail-mounted CX2030 Embedded PC. This powerful PC-based controller features a dual-core Intel® Core™ i7 processor PC and serves as the main machine controller for the lines. “On the MM9 iteration, for example, the small embedded controller has to deliver the processing power needed to drive our complex machine with seven axes of motion along with one five-axis and two three-axis Delta robots, and still have available CPU bandwidth for quality monitoring and potential self-healing software,” says Fontaine. The Beckhoff controllers also provide easy installation and ample processing power for third-party software that runs in a Windows environment, including the customized AI solution that Labplas is implementing for quality control.

Space-saving high-density (HD) EtherCAT Terminals from Beckhoff with 16 channels connect with sensors, valves, terminal cards, solid-state relays (SSRs) and other devices on the machines.

Enhanced productivity and flexibility

By implementing open, PC-based solutions, each upgraded line achieved an ROI of less than one year. Labplas increased the flexibility of its machines to produce more sizes with fewer changeovers. In addition, the company enabled processes for enhanced quality control and the use of robotics to complete processes quickly and at the highest quality.

Beyond increasing quality assurance, Labplas also boosted throughput, achieving an average productivity gain of 25% on its redesigned machines.