Products

TwinCAT

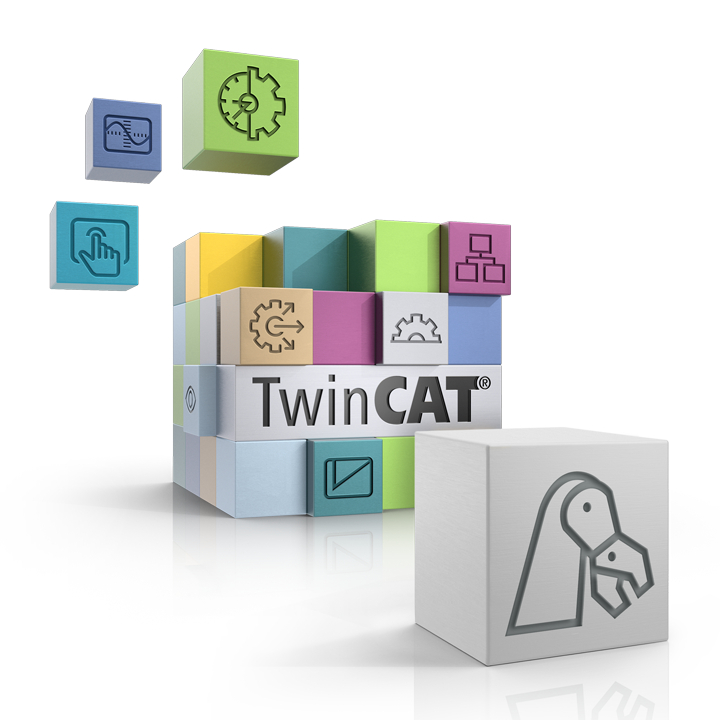

The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.

Add-on software

Extension modules for 3rd-party software such as LabVIEW™, MATLAB® or SOLIDWORKS® for integration into Beckhoff hardware and software

Highlights

Linux®-based real-time control with TwinCAT

Linux® distribution from Beckhoff lays foundation for new type of runtime

Machine learning – for all areas of automation

Beckhoff offers a machine learning (ML) solution that is seamlessly integrated into TwinCAT 3.

TwinCAT projects with AI-assisted engineering

Beckhoff has developed TwinCAT Chat for the TwinCAT XAE engineering environment.

TwinCAT MC3

Beckhoff presents the latest generation of motion software solutions in TwinCAT MC3.

OPC UA

As a pioneer in open standards, Beckhoff offers the possibility of extensive interoperability with third-party products thanks to TwinCAT 3.

Edge device

Fully flexible edge device applications through industry-proven hardware and software from Beckhoff

Module Type Package (MTP)

TwinCAT MTP integrates the Module Type Package concept into the engineering environment and enables efficient development of modular plants.

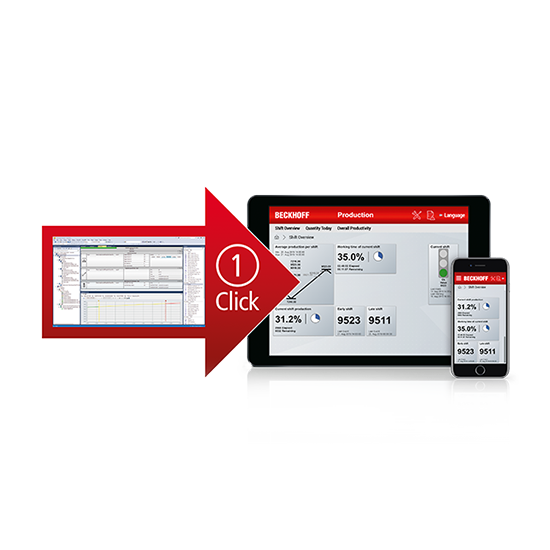

TwinCAT Analytics

The TwinCAT Analytics product family offers a complete workflow for data acquisition, storage, analysis and visualization in dashboards.

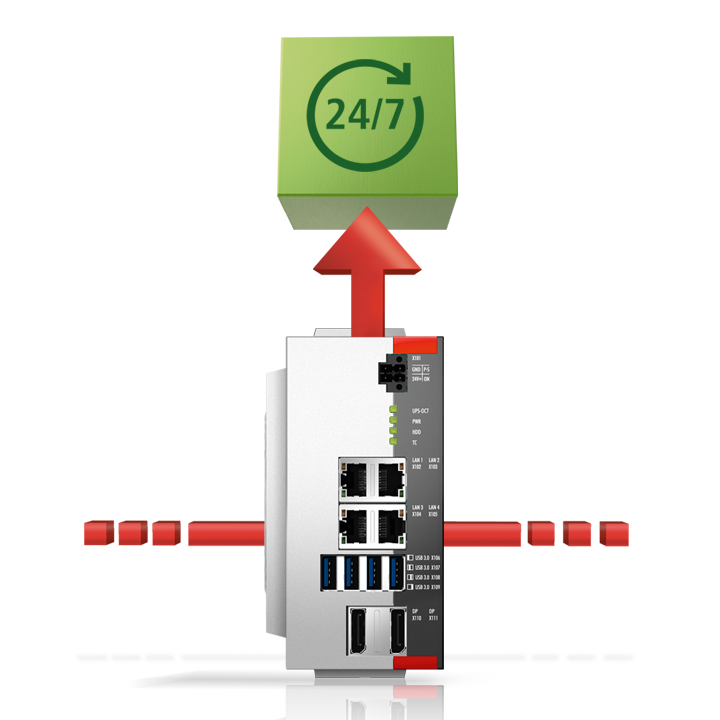

TwinCAT 3 Redundancy

Redundant designs of automation technology ensure your plant availability.

MATLAB® and Simulink® for TwinCAT 3

With the current TwinCAT 3 target products, it is possible to transfer analyses and simulations from MATLAB® and Simulink® directly into the TwinCAT world.

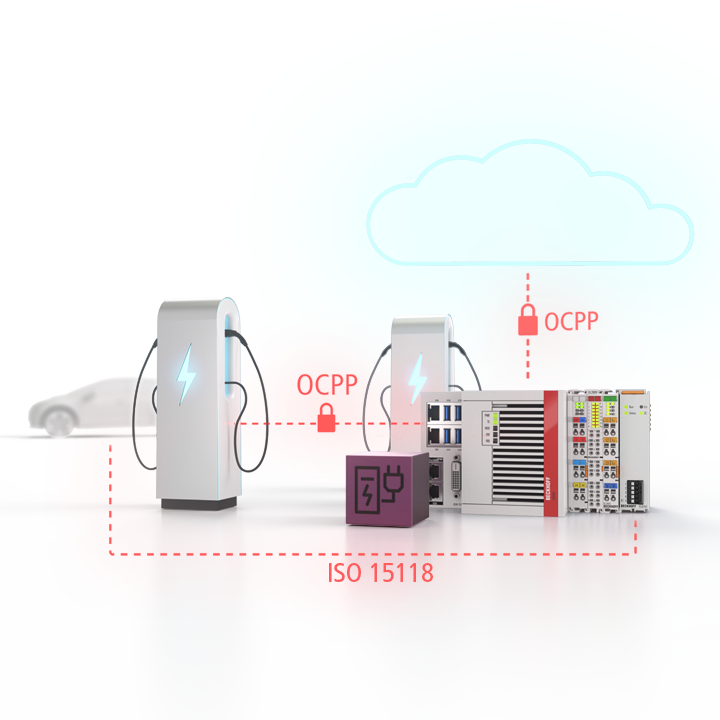

TwinCAT 3 IoT OCPP and EtherCAT Terminal EL6761

The combination of TwinCAT 3 IoT OCPP and EtherCAT Terminal EL6761 creates a universal solution for charging infrastructure communication.

TwinCAT/BSD Hypervisor

Increased availability due to integrated VM environments: TwinCAT/BSD Hypervisor

TwinCAT 3 Scope

The software oscilloscope is fully integrated within the TwinCAT control architecture and enables the simple graphical display of signal curves.

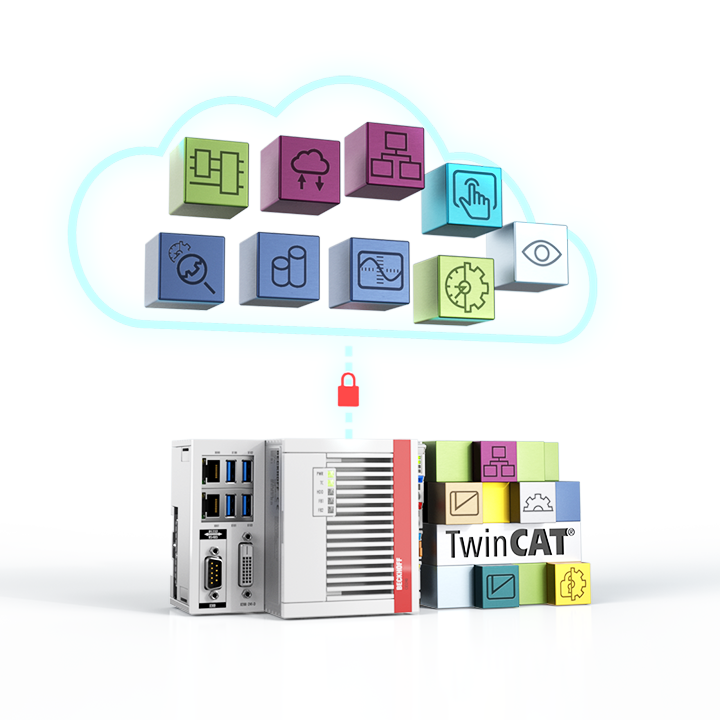

IoT Connectivity with AWS

Beyond the scope of conventional control tasks, applications such as big data, data mining and condition or power monitoring enable the implementation of superior, forward-looking automation solutions.

TwinCAT HMI

By integrating the Human Machine Interface into the engineering environment of Visual Studio® and TwinCAT 3, Beckhoff opens the way for the next HMI generation.

TwinCAT Cloud Engineering

With TwinCAT Cloud Engineering, even globally distributed control systems in Industrie 4.0 environments are easy to operate and maintain remotely.

TwinCAT 3 Kinematic Transformation

The integration of the robot controller into the automation software: execution of PLC, motion control and robotics on one Industrial PC.

TwinCAT 3 Lighting Solution

The TwinCAT 3 Lighting Solution enables simple commissioning of DALI lighting controls.

Industrie 4.0

PC-based Control from Beckhoff as the optimal control architecture for future challenges in the field of Industry 4.0 concepts.

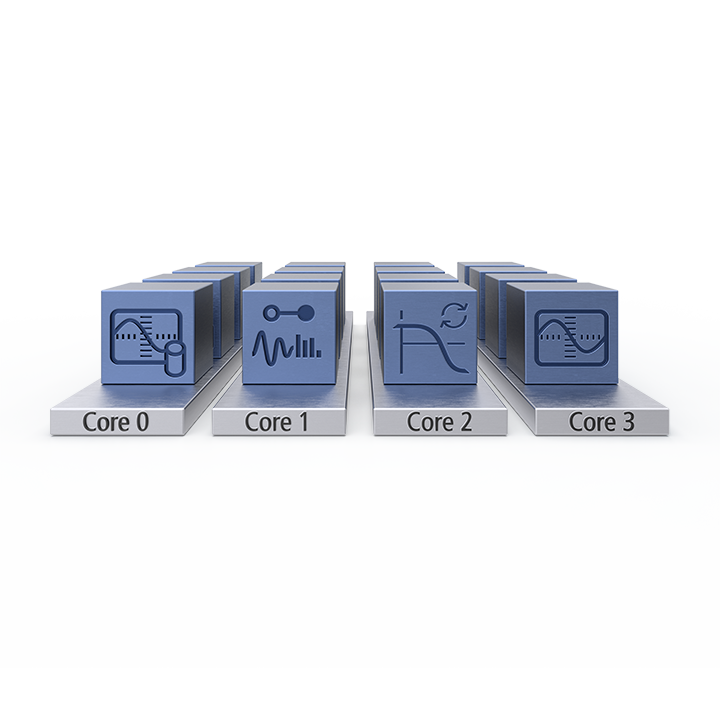

Scientific Automation

Scientific Automation is the integration of automation software with findings from engineering science.

PC-based automation with TwinCAT

TwinCAT 3 automation software integrates real-time control with PLC, NC, and CNC functions in a single package. Beckhoff controllers are programmed uniformly with the TwinCAT Engineering (XAE), according to the programming standards IEC 61131-3 with C++, MATLAB® and Simulink®. The generated code is executed in the TwinCAT Runtime (XAR). The TwinCAT Runtime is a multitasking operating system that runs in parallel on the host operating system. Windows and TwinCAT/BSD in 32-bit and 64-bit variants can be used as host operating systems. In addition to high determinism, the TwinCAT real-time offers the possibility to fully utilize the PC's existing cores in multicore operation.

TwinSAFE

Apart from aids for purely functional automation, Beckhoff provides a comprehensive solution for the field of safety technology in TwinSAFE. The TwinSAFE system offers maximum flexibility in hardware and software, enabling all possible tasks in the field of safety technology to be solved appropriately.