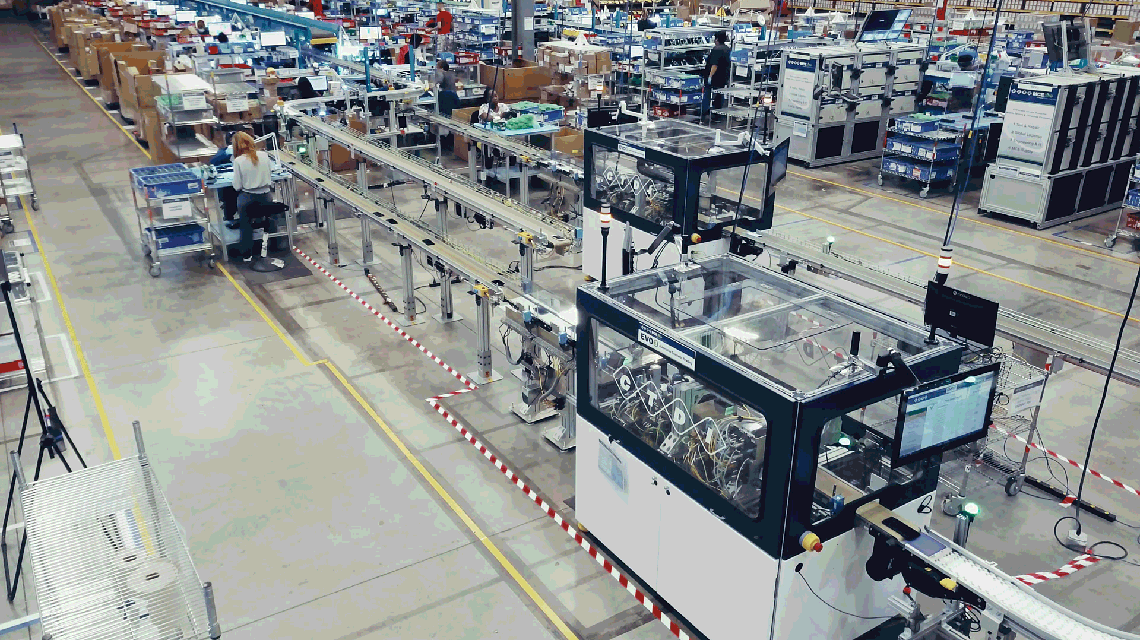

Our control technology has been used in warehouse and distribution logistics for many years to control all equipment of fulfillment operations including sorters, singulators, gappers, AS/RS (automated storage and retrievel), conveyors, picking/induction applications, and other equipment. All over the world, the top global material handling equipment suppliers rely on technology from Beckhoff: In material handling and conveyor technology, in the separation, sorting and packaging of goods, in warehouse logistics or, for example, in controlling AGVs and mobile robots. A large number of references from a wide range of logistics application areas confirm the effectiveness and benefits of our control solution. Exciting applications show you how PC-based control optimizes processes in warehousing and throughout.

Current applications at a glance

Open control solution facilitates system-spanning communication

In a new automated testing and high-bay warehouse for Kunming Shipbuilding Equipment, specialist KSEC Intelligent Technology managed to increase system efficiency and meet the requirements for intelligent manufacturing. Using the open and compact control technology from Beckhoff as a foundation contributed greatly to this success.

Automation upgrades reduce sortation system wiring by 50% and lower costs by thousands

NPI’s singulation and sortation solutions, which leverage Beckhoff controls and EtherCAT, helped a California distribution center reduce difficult-to-fill labor requirements while increasing throughput and decreasing turnaround times.