PC-based control for sheet metal working

Headquarters United Arab Emirates

Beckhoff Automation FZE

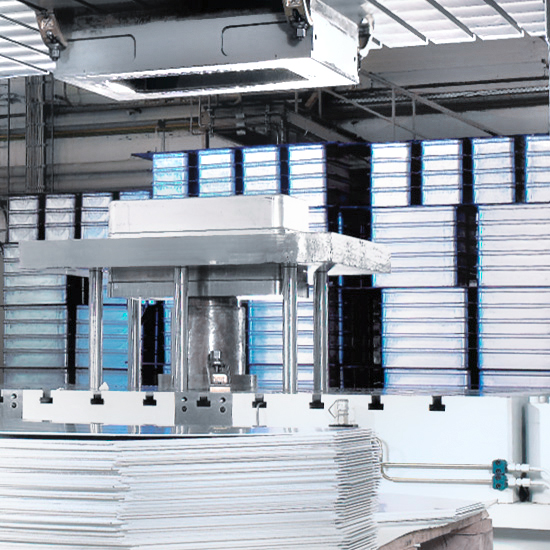

End users and manufacturers of machines for sheet metal working and metal forming are faced with high demands: High productivity must be guaranteed as well as a maximum degree of individualization and high quality standards. In order to be able to produce competitively, the machines must also be optimized with regard to their footprint and energy consumption. In order to meet these requirements, modern automation technology is required, as we offer with PC-based control.

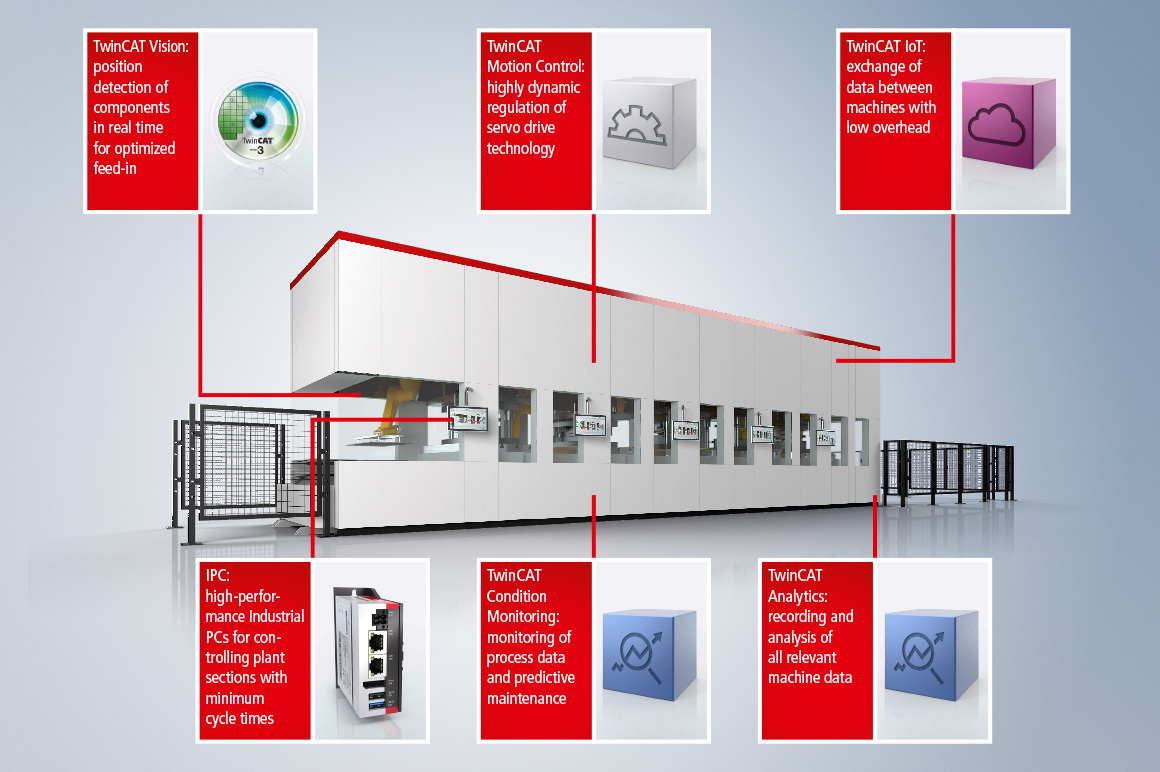

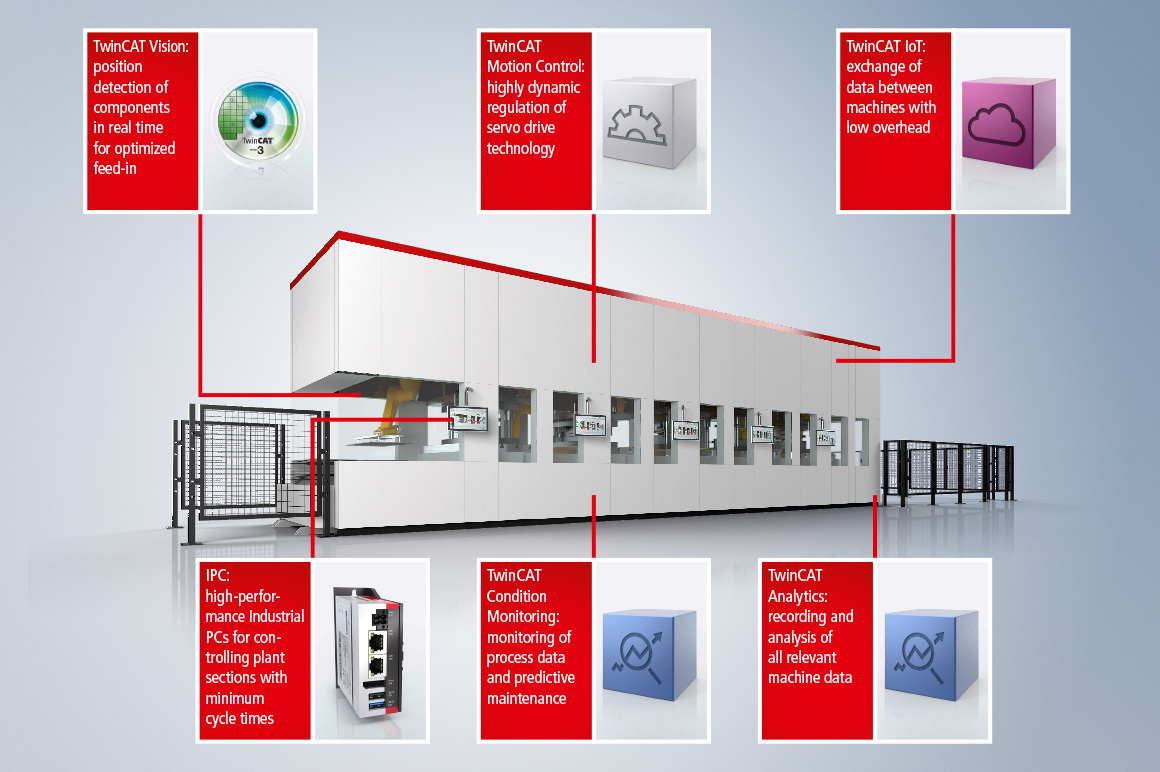

Modular in structure and precisely scalable to meet the requirements of the specific application, PC-based control is suitable for the entire range of requirements – from the single machine to the industrial linked plant. Since all functions are consistently transformed into software, only one CPU is required for PLC, visualization, motion control, safety and measurement technology. In combination with the direct cloud connection Industrie 4.0 concepts can be realized and every process stage can be optimized. Improved production processes, increased workpiece quality and increased output bring clear competitive advantages. The reduced control complexity ensures greater reliability and simpler maintenance of machines and plants.

Beyond the high-performance control technology, EtherCAT and EtherCAT P in particular provide for a competitive advantage in press lines. We offer a wide range of CNC functions for cutting and welding plants. Special applications for punching and nibbling are supported by fast signal processing based on EtherCAT and EtherCAT XFC. With the software library TwinCAT 3 Hydraulic Positioning, ready-made function blocks are available for bending processes in folding, roller bending or pipe bending machines. In addition, you can rely on our expertise acquired over many years of cooperation with our customers in the field of sheet metal working and forming. We offer comprehensive application support for both new plants and machine retrofits.

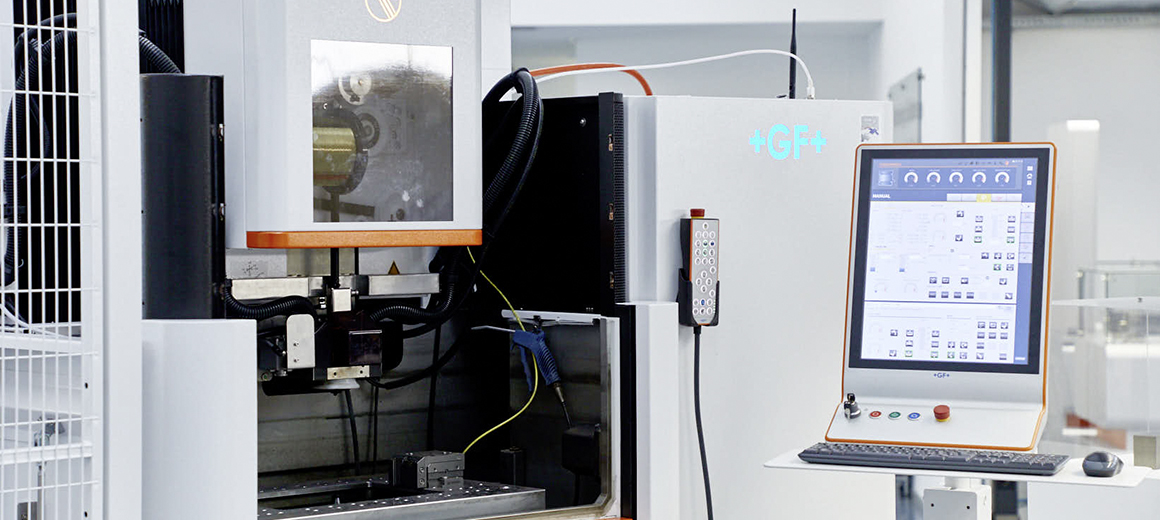

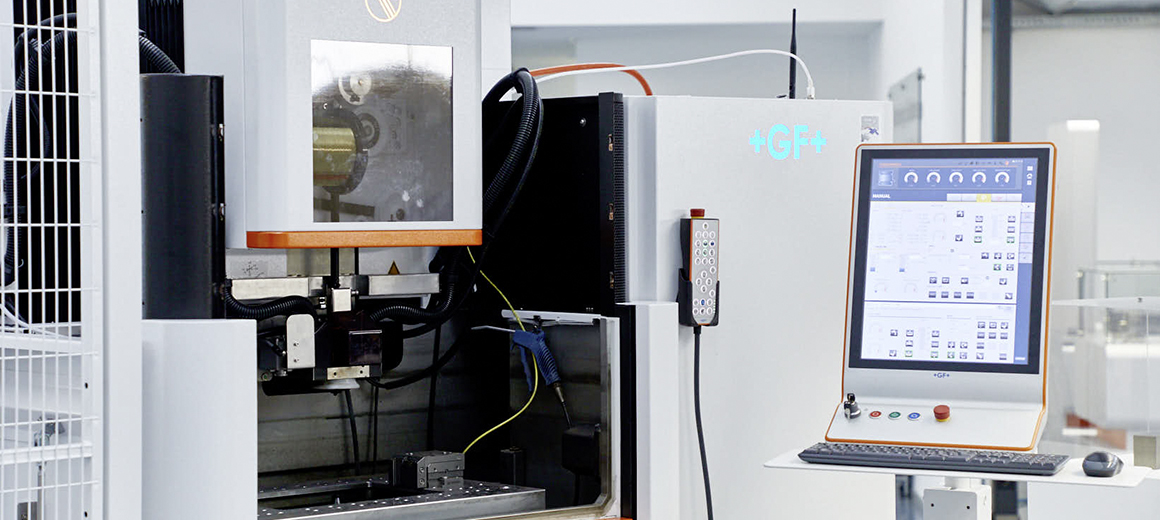

The Beckhoff CNC solution enables highly dynamic axis movements in punching and nibbling.

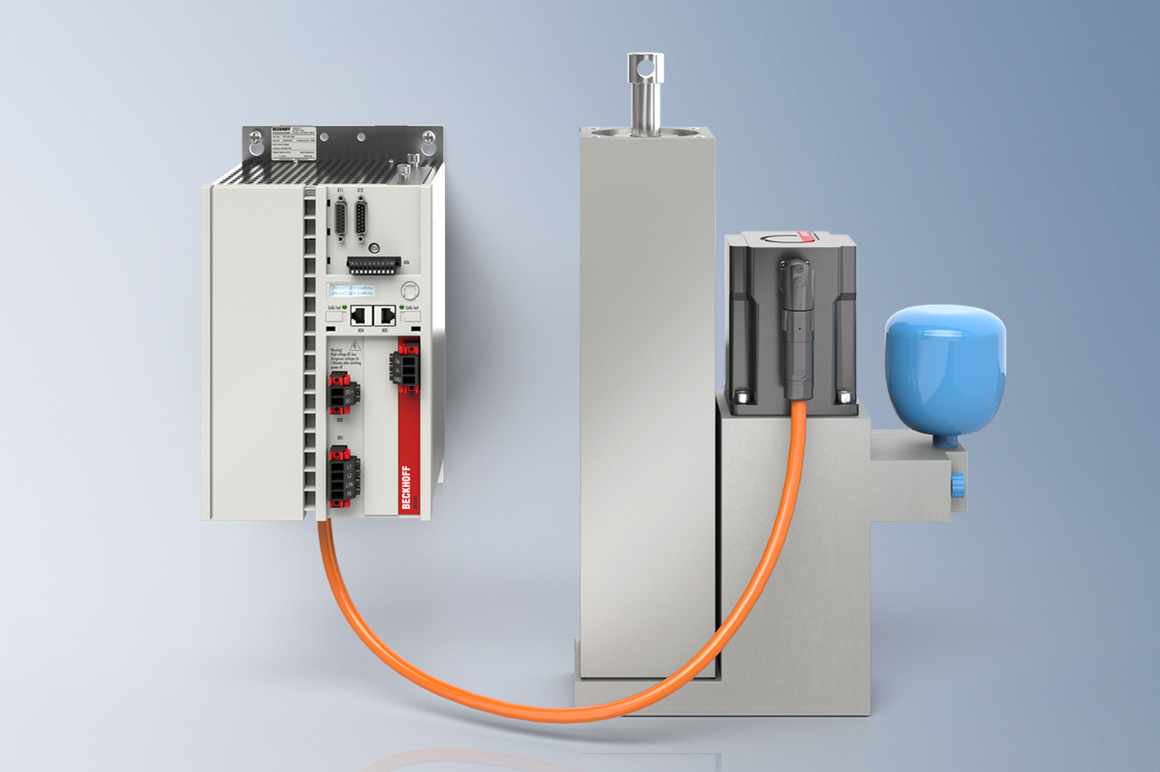

PC-based control from Beckhoff provides the ideal platform to automate folding and bending processes.

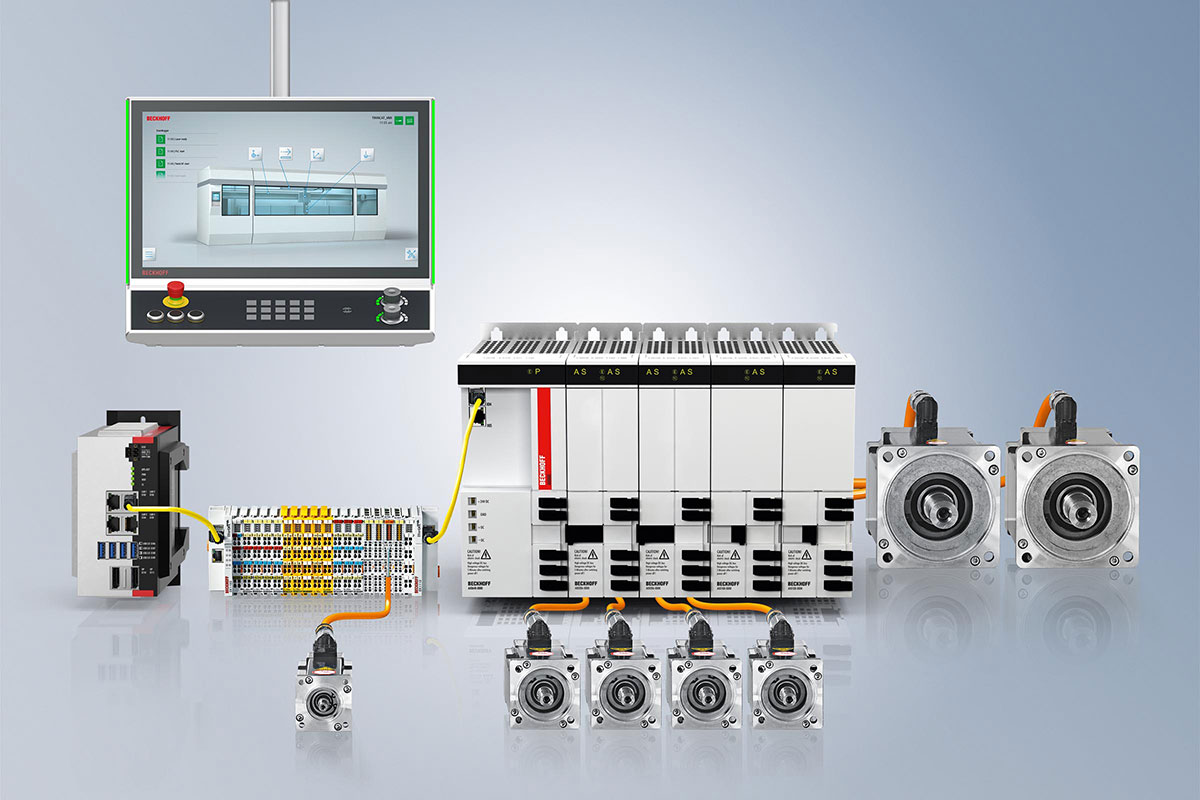

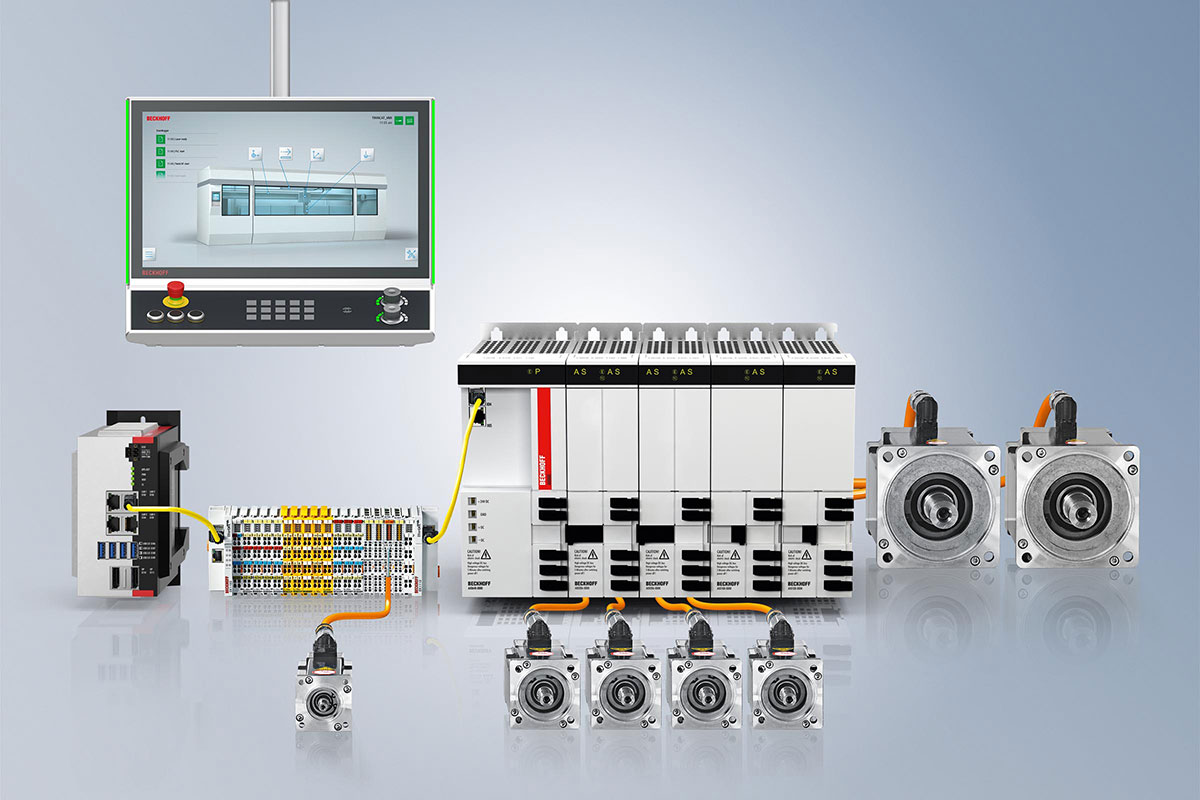

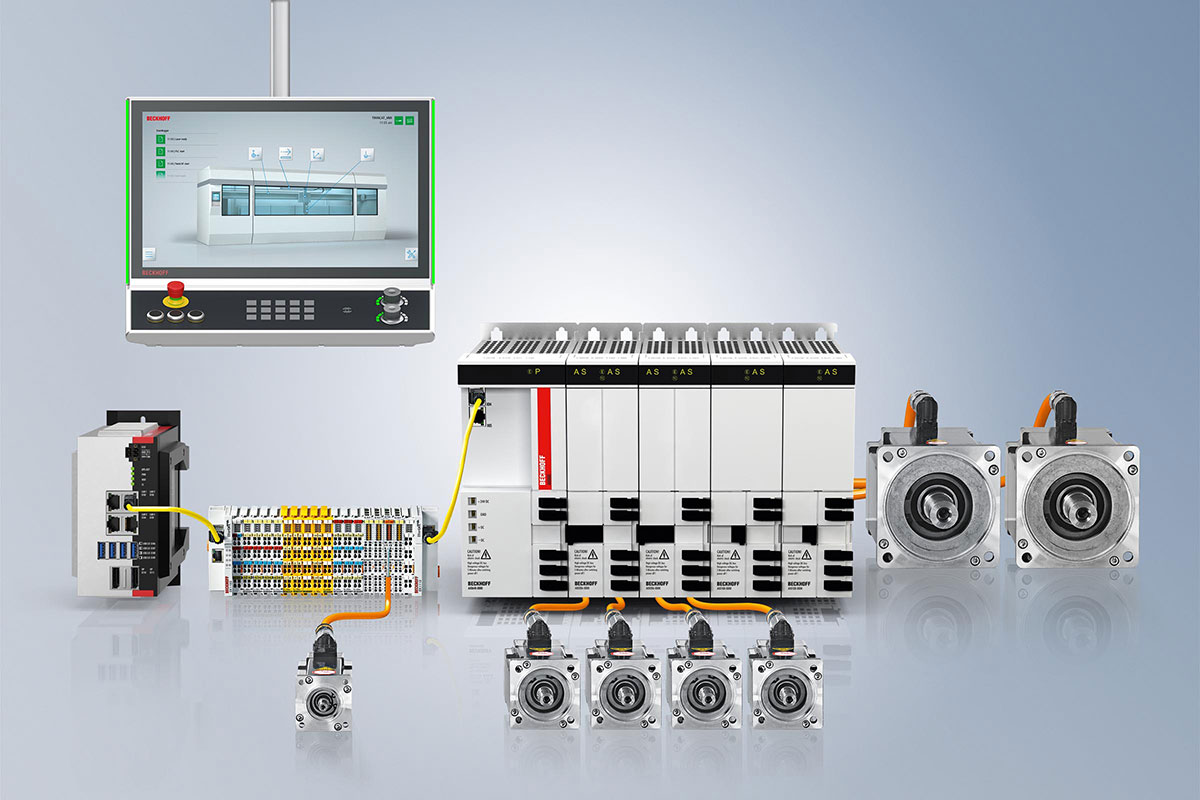

Increasing product diversity, highly fluctuating batch sizes and a strong sense of cost demand maximum flexibility from sheet metal processors. This is precisely where our PC-based control technology offers a decisive competitive advantage: scalable solutions with high performance and precision. With the Beckhoff automation toolkit, control solutions can be configured for the most diverse applications and requirements in sheet metal working: High-performance industrial PCs, multi-touch panels, fast I/O components, EtherCAT as an open and fast fieldbus, dynamic servo drive technology and TwinCAT automation software form the basis for PLC, visualization, motion control, safety and measurement technology. The automation functions are abstracted from the hardware and consistently transformed into software modules. This results in a significantly reduced communication effort, shorter response times and lower costs, both for hardware and for the engineering.

In addition, the standards-based open control architecture with its diverse interfaces in hardware and software offers a high degree of flexibility. Support for common fieldbus systems and software protocols guarantees integrated horizontal and vertical communication: from the networking of individual machines to the IT level and the cloud. The TwinCAT Analytics data analysis software tool can also increase the productivity of the plant: comprehensive condition monitoring allows for predictive maintenance and reduces the downtime of machines and plants.

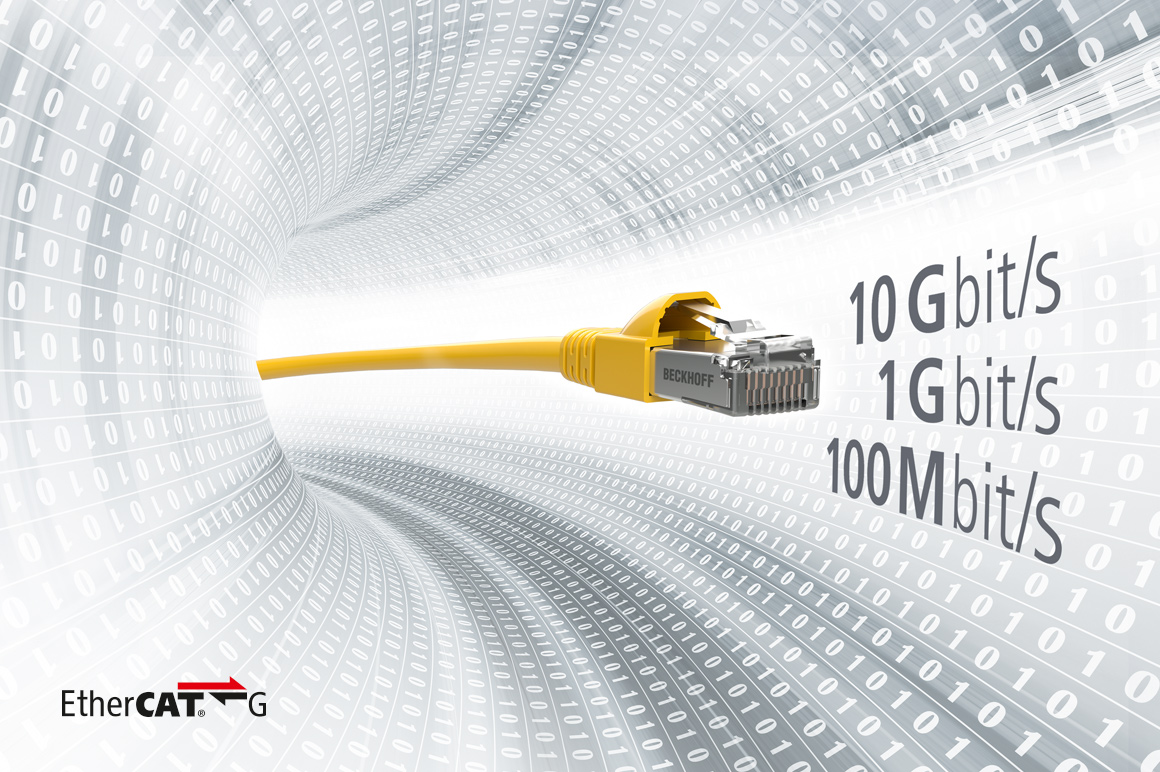

The EtherCAT technology was launched on the market by us in 2003 and made available as an open standard for automation technology. With outstanding performance, flexible choice of topology, comprehensive diagnostics and simple configuration, EtherCAT is ideally suited for use in sheet metal working machines. We offer the largest number of EtherCAT-compatible automation modules for I/Os and for drive technology. In addition, a large number of EtherCAT-compatible sensors and actuators from third-party manufacturers are also available on the market, thus ensuring a high level of investment security. The fast and highly precise eXtreme Fast Control (XFC) solution with I/O response times of less than 100 µs improves the productivity of sheet metal working machines and reduces waste and the consumption of resources.

For high-performance machines and highly complex applications, we have introduced EtherCAT G to the market. As a continuation of the EtherCAT success principle, EtherCAT G provides speeds of 1 Gbit/s or 10 Gbit/s. The transmission rate of 100 Mbit/s currently used by EtherCAT can be increased by a factor of 10 or 100. Both performance stages represent system-compliant enhancements of the EtherCAT technology – the well-known "on-the-fly" principle remains unchanged.

Punching is a highly dynamic process. Stroke rates of more than 2,000 strokes per minute are not uncommon. At these high speeds, a high-performance control platform and extremely fast communication are required in order to make adjustments to the mechanism in the micron range. In particular with high-speed presses, the dynamic effects resulting from the high centrifugal forces can be compensated. TwinCAT automation software and the EtherCAT high-speed communication system are the basic function blocks for this. Cycle times in the lower millisecond or even sub-millisecond range allow fast reaction and response times. Nevertheless, these times cannot be completely eliminated. XFC helps with its distributed clocks (DC): This technology provides the machine with a nanosecond-precise system time. All signals from the field and calculations within the controller are referenced to this time. Thus, several sensors can be evaluated at the same time, as there is a uniform time base.

Another property of XFC, oversampling, is also used to improve the process. This technology is used whenever it comes to acquiring or outputting signals from the machine with an even higher resolution, despite PLC cycle times that have already been set very short. The trick: in an EtherCAT cycle, up to 100 temporally equidistant values of a signal are transmitted at a stroke; the temporal resolution of the signal is also appropriately increased by this factor. The associated, significantly reduced discretization losses increase the positioning accuracy of drives or the accuracy of the detection of workpieces.

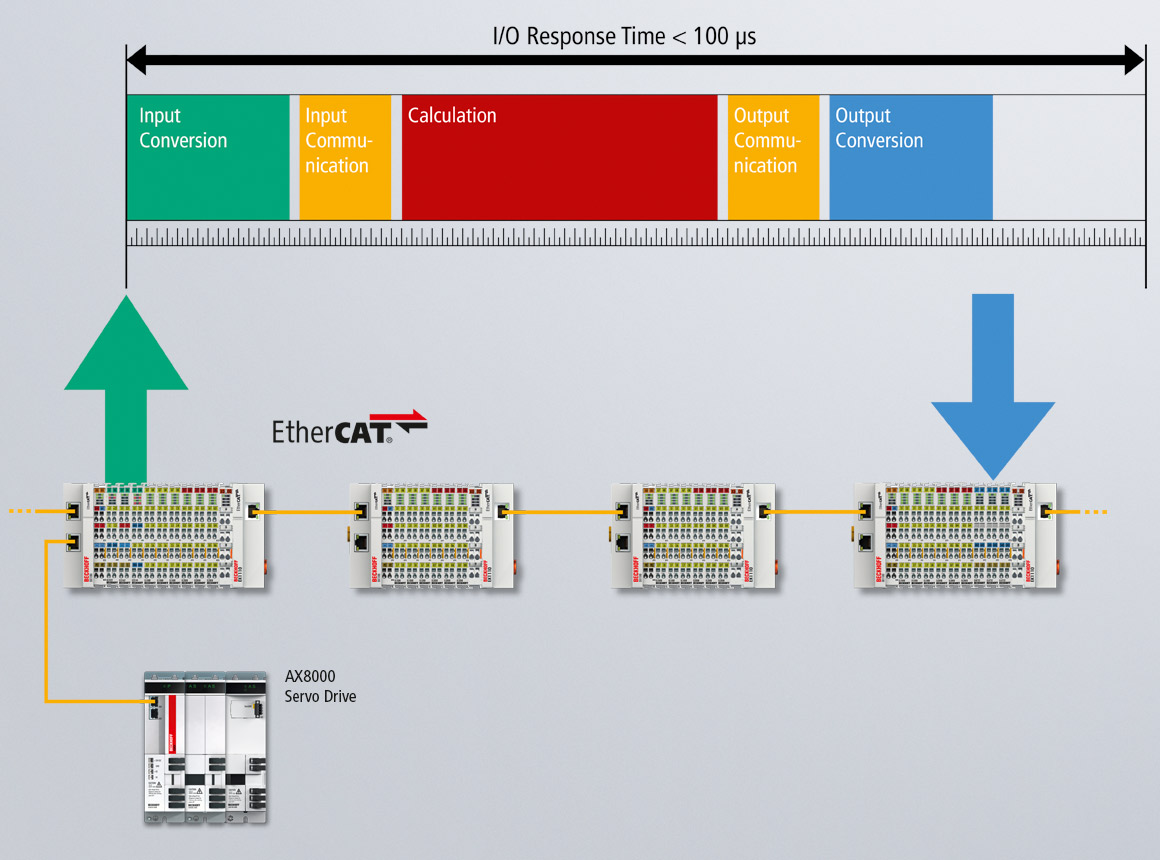

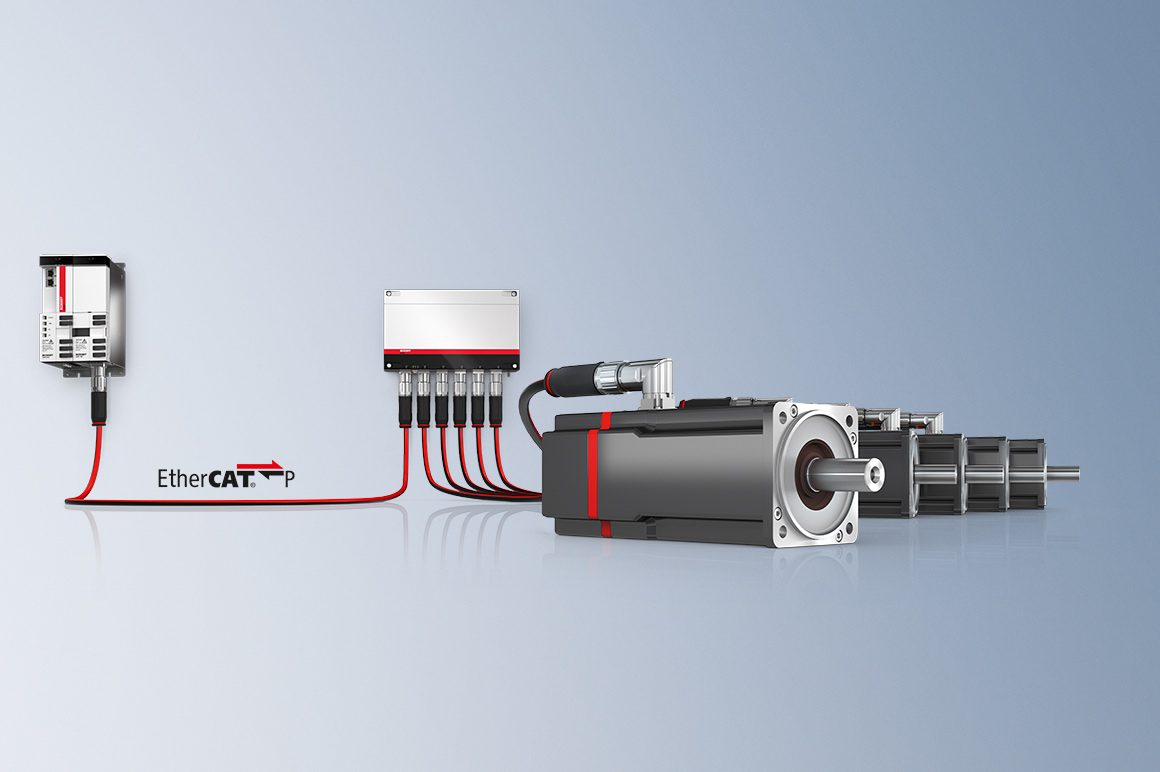

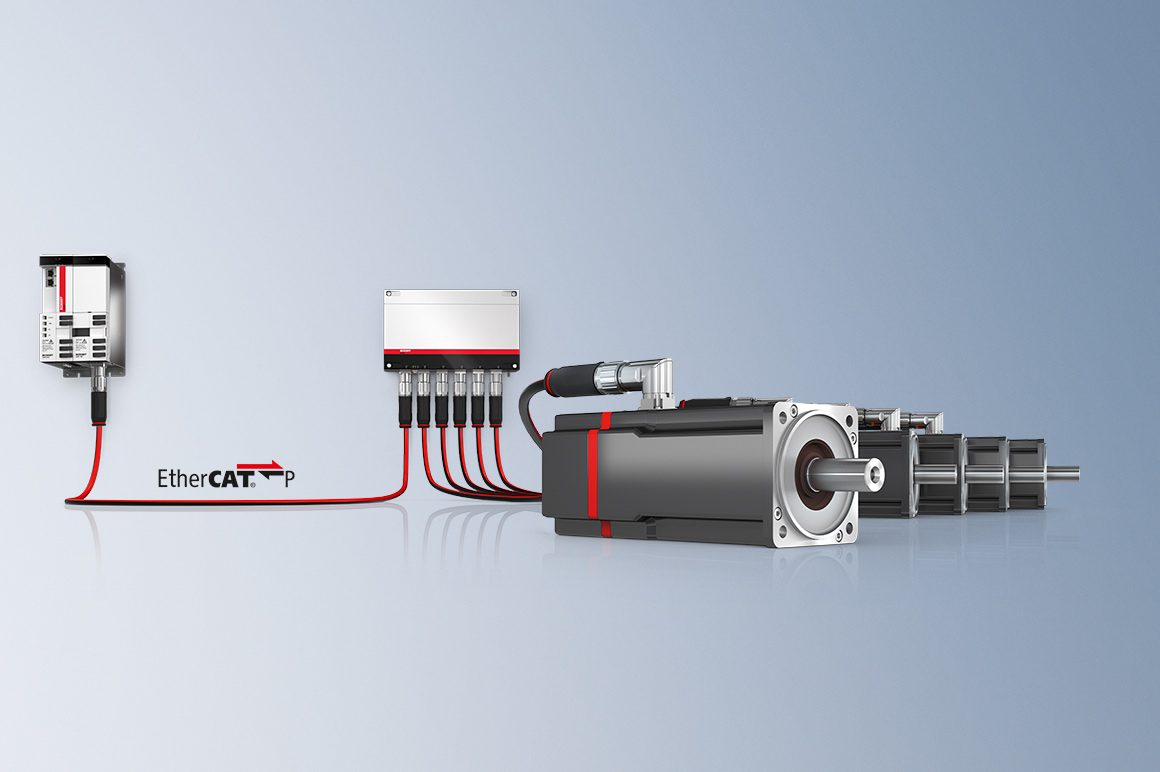

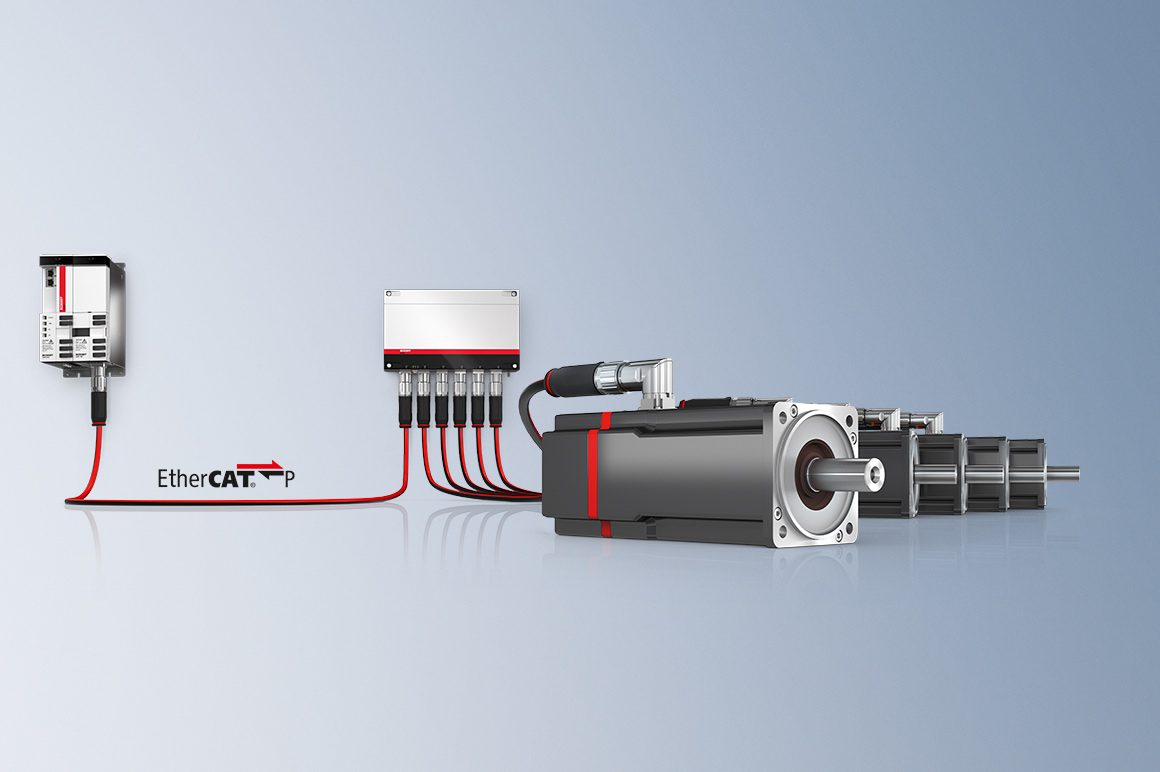

For line systems and modular machine concepts, we offer EtherCAT P, a superior single-cable solution for the field level. EtherCAT P integrates the EtherCAT communication as well as the system and peripheral voltage in one cable. In addition, EtherCAT P enables the direct forwarding of a power supply via the devices. All benefits of EtherCAT are retained, including free choice of topology, high speed, high-precision synchronization, extensive diagnostics. EtherCAT P is the optimum bus system for sensors, actuators and measurement technology in sheet metal processing. In one cable automation, decentralized terminal boxes and individual machine modules are supplied with control data and power via a single cable. The previously familiar, large control cabinets can thus be partly or completely dispensed with, so that the footprint of the plant is significantly reduced.

Thanks to EtherCAT P, it is possible to implement modular machines and system concepts with high flexibility and considerably reduced installation and commissioning effort. Material costs, installation effort and time are saved; the error rate during the installation is reduced. Due to the omission of the power feed it is possible to make sensors and actuators smaller, and the space required in drag chains, control cabinets and in the machine itself is reduced. In other words, EtherCAT P enables above-average performance with low connection costs.

For the first time, the MX-System enables completely control cabinet-free automation solutions in machine and system engineering. The combination of baseplate and function modules resulting from the modular system combines all the tasks and features of a control cabinet: power supply, fuse protection and distribution, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, and the connection level for the field devices. The full system integration of all machine functionalities is achieved via freely selectable IPC, coupler, I/O, drive, relay, and system modules, which can be configured and combined according to the specific application.

The consistently systemic approach of comprehensively coordinated assemblies, certified to international standards, enormously reduces the effort required for planning, assembly, machine installation, and maintenance. Since considerably fewer components are required than in traditional control cabinet design to implement the same requirements, the entire MX-System is significantly more compact than previous solutions. The system footprint is reduced, and system availability and flexibility are also increased. In each life cycle phase of a control system, the MX-System offers significant advantages over the classic control cabinet.

The advantages of the MX-System for sheet metal working at a glance:

In TwinSAFE, we have implemented a universal safety concept that integrates safe functionalities into the standard control platform. All safety functions such as emergency stop, safety door monitoring, two-hand operation, safety mat evaluation and muting, safe position and safely limited speed, can be programmed and configured with TwinCAT. Safety technology is seamlessly integrated into the terminal segment via the TwinSAFE I/O modules, allowing safe signals to mix with standard signals as required.

The typical safety functions can be programmed or configured according to the safety requirements in a TwinSAFE Logic Terminal via standard safety function blocks. All Beckhoff safety controllers are suitable for applications up to SIL 3 according to IEC 61508 or PLe of ISO 13849-1. The safety controllers support complex, safe analog evaluations. With the help of the TwinSAFE SC technology, it is possible to qualify standard signals for safety tasks in any network or on any fieldbus. For this purpose, corresponding EtherCAT Terminals are available.

Large networked plants pose major challenges for all parties involved, especially with regard to safety technology. TwinSAFE offers the option to completely or partially decentralize the safety application as required. Each machine or, if necessary, each unit can easily be equipped with its own safety logic.

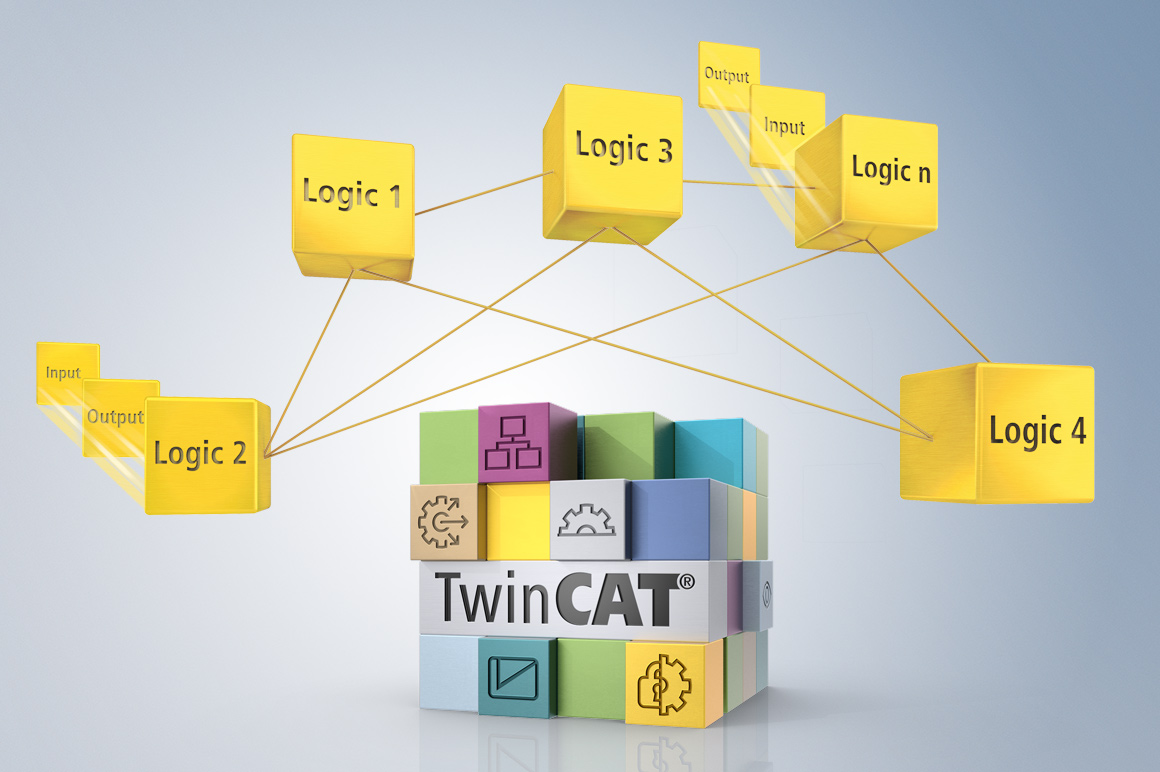

The TwinCAT automation software consists of runtime systems for the real-time execution of PLC, HMI, NC, CNC and robotics applications and is at the same time the development environment for programming, diagnostics and configuration. All main IEC 61131-3 programming languages are available for real-time applications. The object-oriented extensions of IEC 61131-3 enable the modularization of the programming code, the software encapsulation of machine functions and, in conjunction with that, improved structuring, simpler maintenance, re-usability and expandability of the software. C/C++ and MATLAB®/Simulink® modules can be integrated in the IEC context via existing interfaces or operated independently in the TwinCAT real-time environment. Moreover, open interfaces as well as the use of the latest technological standards based on Windows operating systems open up a wide range of options for the user, such as integration in existing visualization, control and database systems. Multi-core and many-core technologies are fully supported by TwinCAT.

Extensive software function modules and libraries for industry-specific requirements facilitate the engineering and implementation of machine functions:

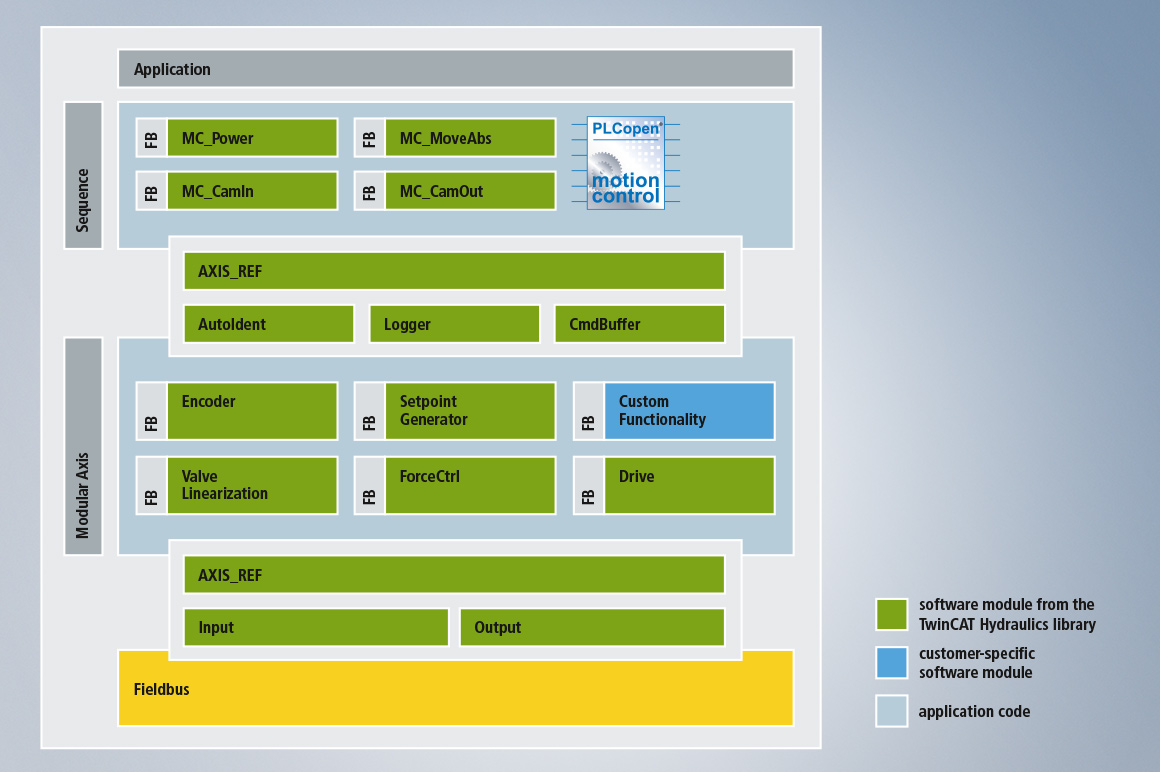

The TwinCAT Hydraulic Positioning library (TF5810) provides all the software functions required for valve- and pump-controlled axes or servo pumps. As a rule, the solution is vendor-independent, so machine manufacturers are free to choose their preferred hydraulics equipment providers. The integration of motion control technology into the PLC makes additional hardware controllers unnecessary and eliminates additional communication effort. At the same time, the software-based architecture offers maximum flexibility for peak motion control performance. The Hydraulics Library uses standardized PLCopen interfaces, which reduces engineering effort. Any hydraulic axes can be optimally operated through adapted set value generators, automatic characteristic curve identification, segmented movements and freely programmable switching between force, pressure and position control. The Hydraulic Positioning Library concept enables advanced motion control for any number of axes with matching CPU performance. Hydraulic axes can be operated in interpolating mode when TwinCAT NC I or TwinCAT CNC is used. Of course, hydraulic drive systems need different interfaces for sensors and hydraulic components. Therefore, the TwinCAT Hydraulic Positioning Library supports all common interfaces in conjunction with Beckhoff I/O systems.

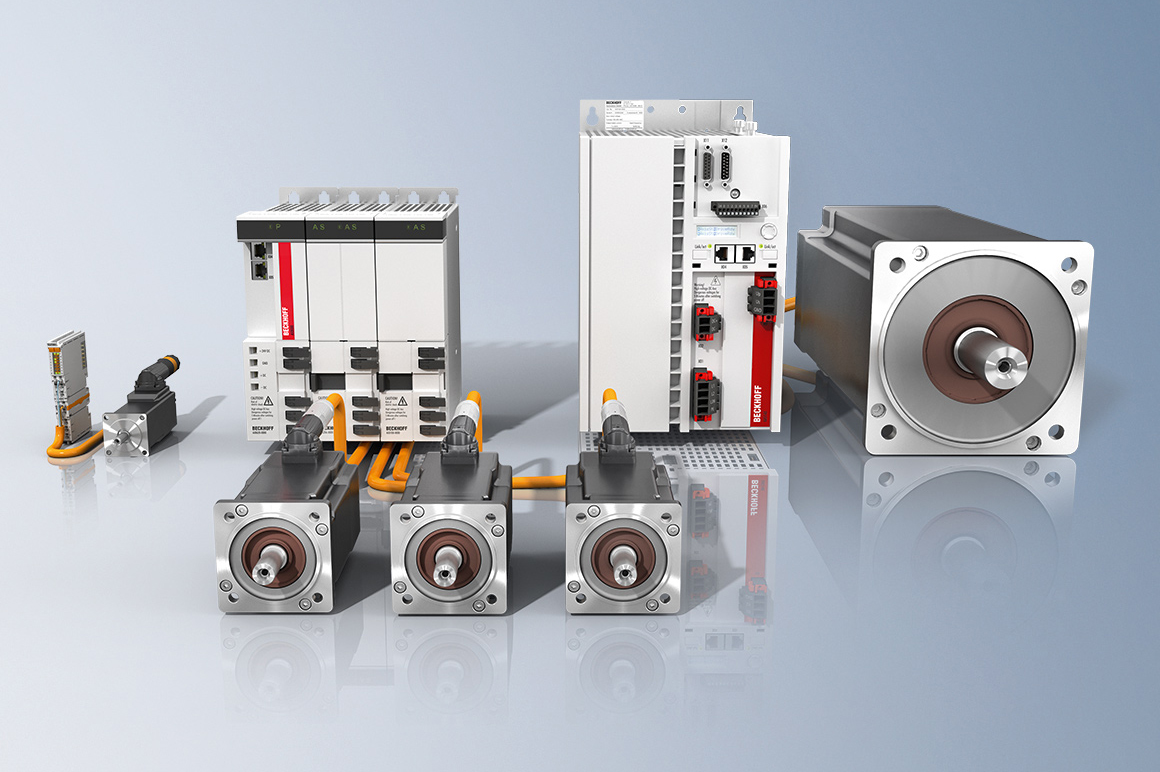

In combination with the motion control solutions offered in the TwinCAT automation software, the Beckhoff drive technology represents an advanced and complete drive system. It is modular and highly scalable, offering the right solution for every area of application and every performance requirement. This ranges from space-saving servo terminals for ultra-compact drive technology to the AX8000 and AX5000 EtherCAT Servo Drives for medium to upper performance classes. The integrated advanced control technology of the AX series supports fast and highly dynamic positioning tasks. The extensive range of linear and rotary servomotors is optimally tailored to the servo drives and is suitable for highly dynamic and accurate multi-axis positioning requirements.

The AM8000 servomotor series is distinguished by the One Cable Technology: it combines power and feedback signals in one standard motor cable to reduce hardware and commissioning costs, permitting the design of lighter and more compact machine tools. Further encoder signals (EnDAT 2.2) can be connected via an optional multi-feedback card. The EtherCAT servo terminals represent an inexpensive and compact alternative for applications with small forces. Solutions up to 8 A are available in the I/O system along with the option to connect stepper, servo, DC and AC motors with IP20 or IP67 protection.

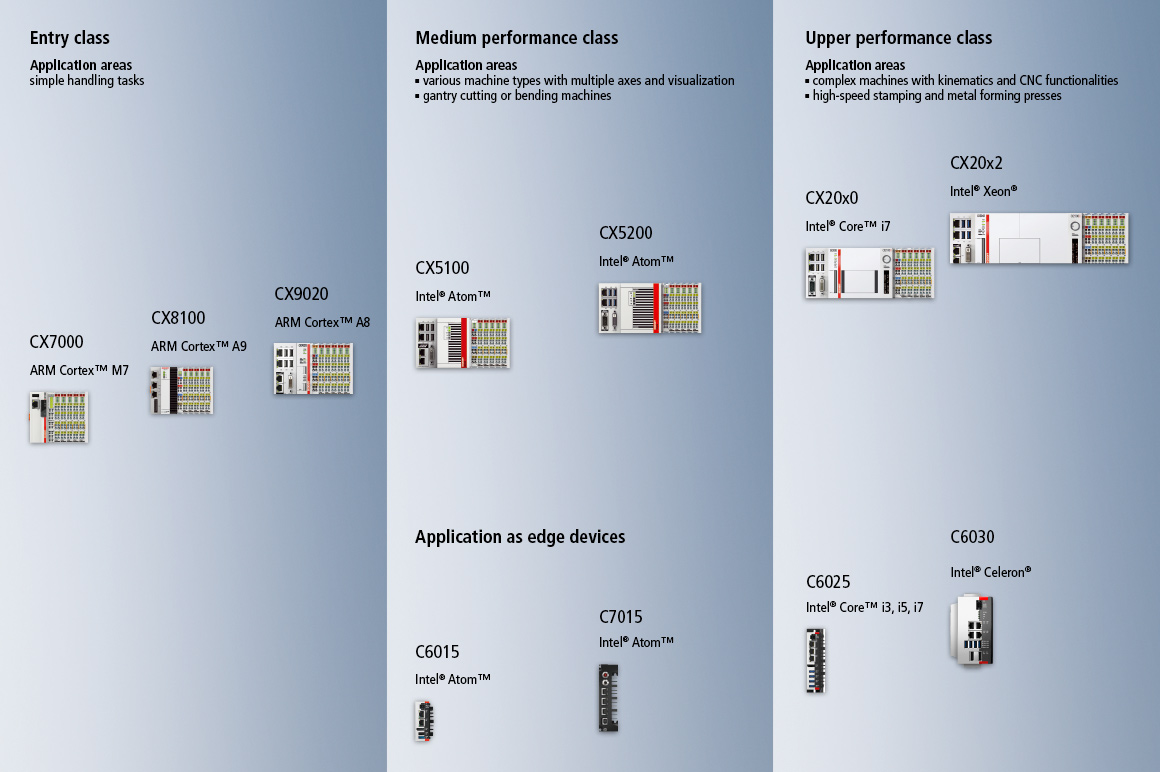

With the C60xx industrial PC Series, Beckhoff meets the requirements of the sheet metal working industry with regard to sturdiness, scalability of performance and low space requirements. The C60xx series is ideally suited for control, visualization and communication, for example into the cloud. The latest Intel® processors − in three different performance classes, from the Intel Atom® with one core to the Intel® Core™ i7 with eight cores – offer maximum scalability and power density with an optimal price-performance ratio.

To prevent fluctuations in the IPC supply voltage, the industrial PCs from the C60xx series can optionally be extended by a UPS of the type CU81xx. The UPS ensures that important control and operating data are saved securely in the event of major voltage drops and that the Industrial PC is shut down in a controlled manner. A quick restart of the plant and thus a high availability is guaranteed.

The industrial PCs from the C60xx series offer an additional advantage for use in press because almost no mechanically movable parts are installed. The only exception is the C603x series, which is equipped with a speed-controlled fan.

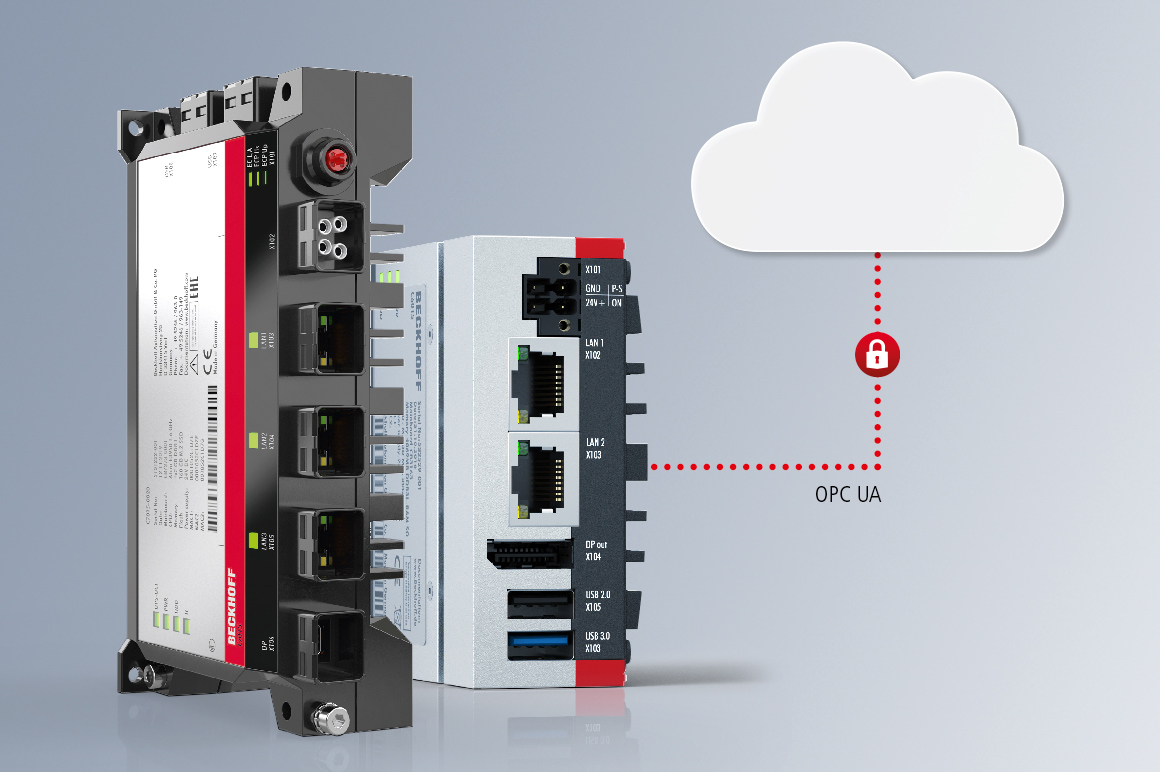

Beckhoff has developed the TwinCAT IoT software library for communication between the machine controller and cloud-based services. It supports the standardized protocols OPC UA, AMQP and MQTT for communication with popular cloud systems such as Microsoft Azure™ and Amazon Web Services, as well as private cloud systems in the company's own network. Built-in security mechanisms prevent the misuse of data through unauthorized access and protect the company's intellectual property.

TwinCAT Analytics is used to record and evaluate the process data in synchronization with the machine cycle. With the corresponding analysis tools, all necessary information for predictive maintenance or for the optimization of the machine with regard to energy and process can be derived from the stored data. Post-mortem analyses, diagnosis of sporadic errors, early detection of quality losses and detection of production bottlenecks increase plant reliability and availability.

TwinCAT Cloud Engineering enables the instantiation and use of existing TwinCAT engineering and runtime products directly in the cloud. It is accessed simply via the Beckhoff website.

For the machine manufacturer, the ergonomic operation and the unmistakable appearance of a machine play a significant role in its success on the market. In addition to design and color, the Control Panel is of great importance as the front end of a machine. More and more mechanical engineering customers therefore want an industry or customer-specific user interface as a unique selling point. Based on an extensive portfolio of standard Control Panels and Panel PCs, Beckhoff offers a wide range of solutions with regard to technical form and design.

A panel design that matches the appearance of the machine in color and dimensions underlines its innovative character. There are no limits to the implementation of the customer's wishes: from the customer-specific company logo inserted in the factory and the color scheme to match the machine design, to the completely individually designed panel on the basis of an individual device design.

In order to meet the needs of the industry for ergonomic operation, Beckhoff offers Control Panels and Panel PCs that are optimally suited to the various processes. The needs-based design of the standard panels through the integration of manually operated push buttons and switches makes machine operation more comfortable. Based on in-depth knowledge of the individual process steps in sheet metal working and metal forming, an industry-specific panel is created from a Beckhoff standard panel without a great deal of development work and expenditure.

TwinCAT NC Interpolation (NC I) is the NC system for interpolated path movements and robotics that replaces conventional axis assemblies. Due to the direct connection to the TwinCAT PLC and the TwinCAT Motion functions, NC tasks can be solved in different processing machines. Powerful software libraries for various robot kinematics supplement the TwinCAT NC I for diverse motion tasks. TwinCAT NC I uses the PC's power and enables axis control on Windows.

At the same time, TwinCAT CNC offers extensive CNC functionality as a pure software solution on a PC basis. TwinCAT CNC covers the complete range of classic CNC path control, including high-end systems for complex motion and kinematics requirements. A maximum of 128 interpolating axes can be controlled with up to 20 channels with extensive coordinate and kinematic transformations. Through support for multi-core and 64-bit operating systems, TwinCAT 3 opens up performance reserves that can be utilized for high-precision control of high-speed laser cutting machines, for example. The .Net-based CNC user interface covers as standard the basic functions such as on-line language changeover, setup functions, global message system and user management. Application-specific parameterization and expandability allows customer requirements to be implemented flexibly and quickly. The scalable Beckhoff CNC solution is available in all performance classes: from compact Embedded PCs with integrated I/O interfaces to Industrial PCs with multi-core processors. The user can choose between optional functions and scalable hardware platforms to configure a performance-based, efficient and cost-effective CNC control system.

The AMP8000 distributed servo drive system breaks new ground in modular machine design. The AMP8000 integrates the servo drive into the servomotor in a very compact design. Relocating the power electronics directly into the machine reduces the space requirement in the control cabinet to a single coupling module, which supplies several servo drives with only one cable via a distribution module. This leads to significant savings in material, space requirements, costs and assembly work. A power supply module executed in a high protection rating even relocates the entire system into the machine. With its few components, the AMP8000 system is easy to configure. Only a single type of cable is needed to connect supply modules, distribution modules and drives with each other. Other components such as motor chokes, fuses or filters are not required for the operation of the system. All connection and power supply modules also have an EtherCAT P connection for the Beckhoff I/O portfolio. This significantly simplifies the connection to additional inputs, encoders or latch units.

There is a wide range of applications for controller-integrated image processing in sheet metal working: During the feeding of parts, the position and shape of the raw materials can be detected and the feeding robot can be prepared for the method of gripping a part. Furthermore, the position and shape of the raw material can also be used to determine how, for example, a nesting plan can be adjusted in a cutting machine in order to minimize waste. Optical quality monitoring has long been known in sheet metal working, too. However, due to integration costs and the lack of complete solutions, it has not yet been established as a standard. The approach of PC-based control technology from Beckhoff offers the ideal solution here. With TwinCAT Vision, the image processing functions are fully integrated into the machine programmer's well-known engineering environment. This simplifies programming and makes the test run much simpler. All control functions derived from image processing, such as the exact determination of the position of the workpiece or the triggering of the camera and the light source, are synchronized in real-time. This is a key advantage of the integrated image processing solution over separate systems.

The strengths of hydraulic drive technology such as a fast motion cycle and low mounting requirements are offset by higher maintenance costs and poor efficiency. Low-maintenance and energyefficient solutions for sheet metal processing are now available with servo-hydraulic hybrid axes. Beckhoff Drive Technology is the ideal complement to these innovative concepts. The highly dynamic servo drive technology enables short machine cycles with low energy consumption. The software library TwinCAT PLC Hydraulic Positioning is ideally suited for the use of hybrid axes in different machine concepts. Design-related irregularities of the oil flow in pumps are minimized through optimized algorithms. The adaptive parameter switching during the motion enables the switchover from position to pressure control with perfectly adapted parameters in each case.

The energy consumption in punching or nibbling varies depending on the process, but is in principle very high and represents a considerable cost factor. Energy efficiency is therefore an essential building block for sustainable production. Beckhoff supplies performance and cost-optimized software and hardware components for the continuous monitoring of energy consumption for the detailed consumption analysis of new developments:

With the CX series of Embedded PCs, Beckhoff combines PC technology with the modular I/O level on the DIN rail in the control cabinet. By adding or eliminating modules and interfaces, only the components that the user needs for the respective application are installed. In this way, the Embedded PCs open up a wide range of applications.

Due to its sturdiness, the CX is suitable for use as a powerful and reliable controller under harsh industrial conditions, such as vibration or heat. The fine scalability in different device classes allows the user to select exactly the right performance category for his application. For example, the high-performance CX5100 and CX5200 control PCs are available for nibbling machines or their peripherals. The CX20xx and CX20x2 device series are high-end controllers that allow for complex user interfaces, the integration of image processing, the realization of Machine Learning or the aggregation of large quantities of data.

Even smaller than the compact design of the Embedded PC devices is the series of ultra-compact Industrial PCs, which is therefore suitable as an alternative, especially when it comes to minimizing mounting space. While the C6015 is suitable for control tasks in the lower performance category, the C6030 meets the requirements for a standard controller. Another advantage is the flexible mounting: while the CX can only be installed horizontally, the devices from the C60xx series can be installed in any position.

Another advantage of the Embedded PCs – as with Beckhoff's entire Industrial PC portfolio – is the long-term availability of spare parts, which offers the customer a high level of investment security.

Modern plant concepts aligned to Industrie 4.0 and the Internet of Things (IoT) offer numerous advantages in terms of process efficiency, costs and quality. Beckhoff has integrated OPC UA interfaces into its automation platform for standardized communication between machines and master computers and for secure data transmission to cloud systems. Older machine generations can be made fit for the requirements of the digital factory with the C6015 ultra-compact Industrial PC. As a compact and powerful IoT edge device, it handles the compression and collection of data.

Since machines in the field often lack the mounting space for additional control components, Beckhoff offers the ultra-compact Industrial PCs from the C70xx series in protection rating IP65/67. The C7015 is mounted on the outside of the machine. Sensors, for example for condition monitoring, are read in via the EtherCAT P interface with the aid of the EtherCAT P Box Modules. This allows for the fast, uncomplicated retrofitting of existing systems with standardized access to the cloud.

In order to continue to use myBeckhoff, you need to agree to the export control and sanctions compliance terms.

If you do not agree to these terms, you will automatically be logged out of myBeckhoff.