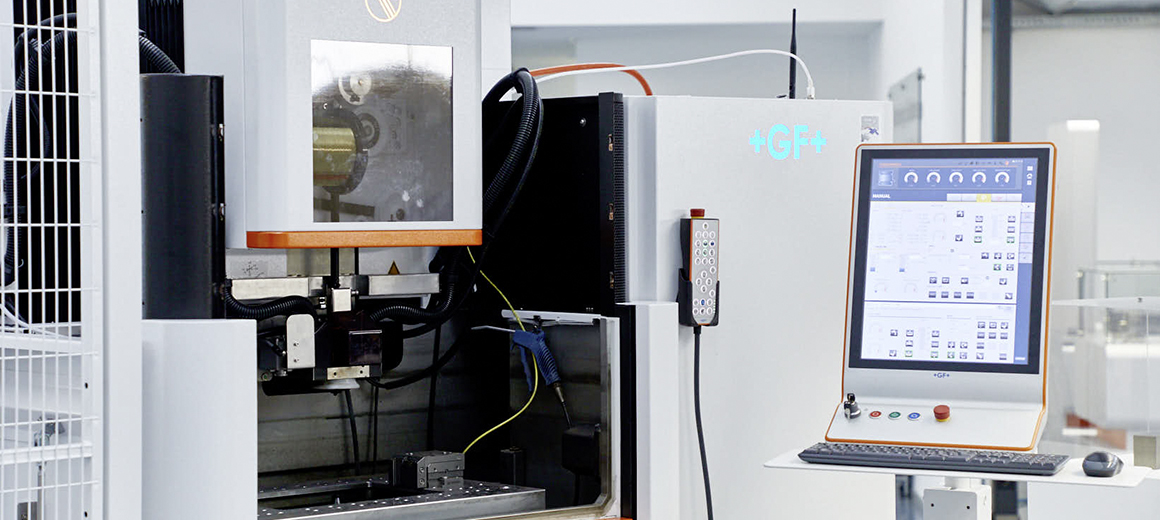

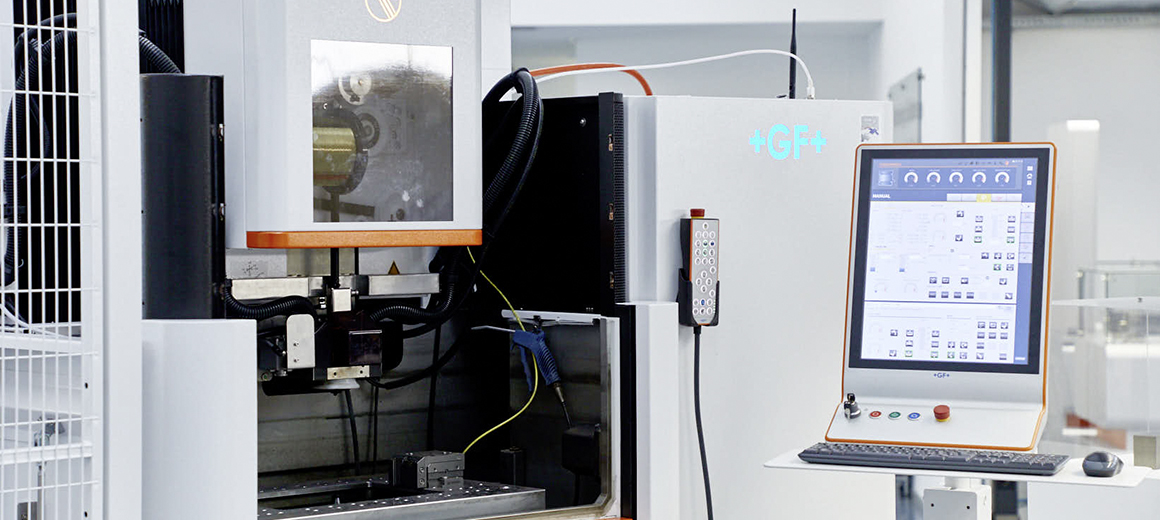

PC-based control for sheet metal working

Sede centrale Svizzera

Beckhoff Automation AG

End users and manufacturers of machines for sheet metal working and metal forming are faced with high demands: High productivity must be guaranteed as well as a maximum degree of individualization and high quality standards. In order to be able to produce competitively, the machines must also be optimized with regard to their footprint and energy consumption. In order to meet these requirements, modern automation technology is required, as we offer with PC-based control.

Modular in structure and precisely scalable to meet the requirements of the specific application, PC-based control is suitable for the entire range of requirements – from the single machine to the industrial linked plant. Since all functions are consistently transformed into software, only one CPU is required for PLC, visualization, motion control, safety and measurement technology. In combination with the direct cloud connection Industrie 4.0 concepts can be realized and every process stage can be optimized. Improved production processes, increased workpiece quality and increased output bring clear competitive advantages. The reduced control complexity ensures greater reliability and simpler maintenance of machines and plants.

Beyond the high-performance control technology, EtherCAT and EtherCAT P in particular provide for a competitive advantage in press lines. We offer a wide range of CNC functions for cutting and welding plants. Special applications for punching and nibbling are supported by fast signal processing based on EtherCAT and EtherCAT XFC. With the software library TwinCAT 3 Hydraulic Positioning, ready-made function blocks are available for bending processes in folding, roller bending or pipe bending machines. In addition, you can rely on our expertise acquired over many years of cooperation with our customers in the field of sheet metal working and forming. We offer comprehensive application support for both new plants and machine retrofits.