Interview on the development of the EtherCAT plug-in modules in the EJ series

When Beckhoff launched the EJ series of EtherCAT plug-in modules back in 2014, it added a completely new design to its broad I/O portfolio. In this interview, Torsten Budde, Product Manager I/O, takes a look at the many advantages – particularly for series machine manufacturing – and the corresponding successful market launch.

How has the market success of the EtherCAT plug-in modules developed since they were first launched in 2014?

Torsten Budde: Even back in the early years, many prototype machines were equipped with the EJ system, and new machine generations were planned based on a signal distribution board with EtherCAT plug-in modules. These have now successfully gone into series production, which has led to a significant increase in the number of units for this new I/O design.

What are the largest application industries or areas right now?

Torsten Budde: In addition to classic series machine manufacturing – for example, in the plastics industry or the machine tool sector – the use of EtherCAT plug-in modules is increasing due to their compact design, especially in semiconductor manufacturing, robots and driverless transport systems. In the latter segment, the current boom in e-commerce in particular increases demand. Traditional mechanical engineering is also showing very good growth figures with numerous projects such as those in the field of electromobility.

What have been the most important additions to the EJ portfolio since 2014, and to what extent has the technology benefited from the comprehensive Beckhoff I/O expertise?

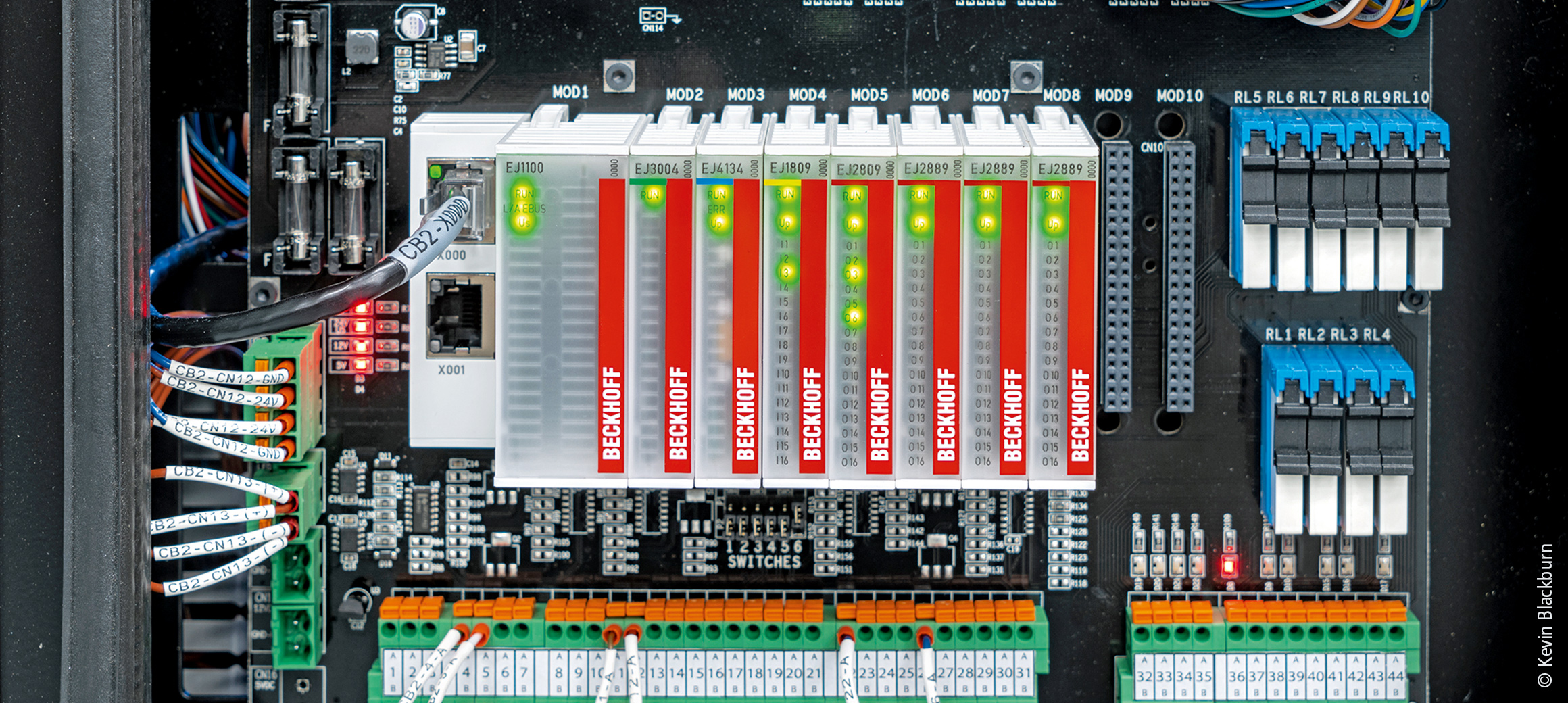

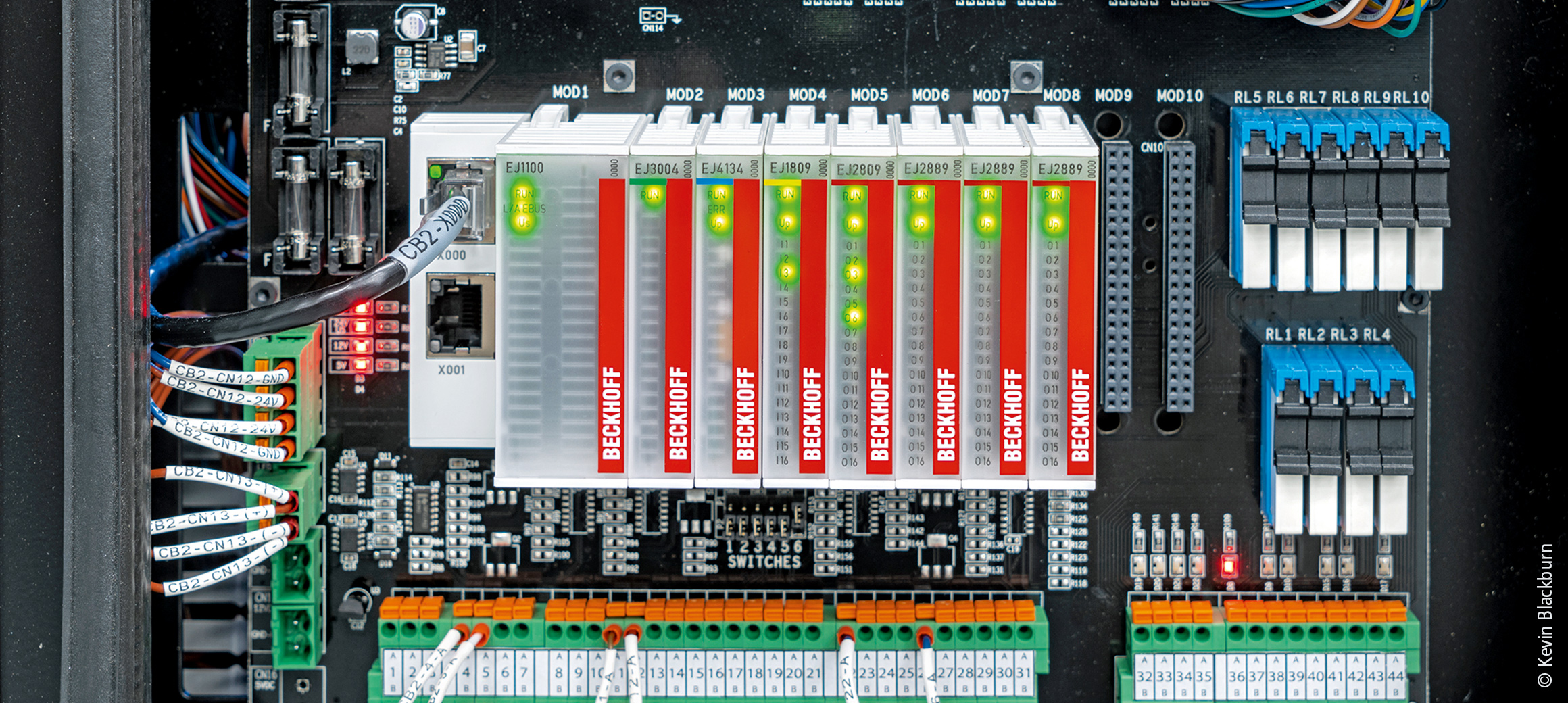

Torsten Budde: Well, it goes without saying that the EJ series clearly benefits from the broad EtherCAT I/O portfolio, which serves as the basis for the development of new pluggable I/O modules featuring tried-and-tested technology. In addition to the digital and analog plug-in modules, an important step is the integration of TwinSAFE and motion functionalities in the compact EJ form factor. With the EK1110-0043 EtherCAT EJ coupler, it is even possible to mount Embedded PCs in the CX series and EL Terminals onto the signal distribution board.

What is the best way to describe the function of this application-specific circuit board, known as a signal distribution board?

Torsten Budde: With the signal distribution board, the individual wires in the classic control cabinet are implemented as conductor tracks on the circuit board. Signal distribution takes place directly on the circuit board from the modules to the connectors of the cable harnesses – hence the name signal distribution board.

The signal distribution board can either be designed by the customer or purchased as a product from Beckhoff. What are the criteria influencing the decision-making process here?

Torsten Budde: First and foremost, the fundamental question for the customer to ask themselves is whether or not they have an in-house development department with the necessary expertise in circuit board development. If the answer is no, then the signal distribution board can also be developed and produced by Beckhoff. If the customer decides to develop in-house or with a local partner, all the necessary documentation and guidelines for smooth implementation can be found on the Beckhoff website. As our customer base continues to expand, more and more customers are opting for their own in-house development, as many industries have the necessary resources in place.

What criteria can machine builders use to determine whether the EJ concept or the terminal technology is more suitable for setting up their own I/O level?

Torsten Budde: The main criterion is the number of machines produced per year. In addition, the compact dimensions of the EJ system mean it can be installed in even the smallest of spaces, such as in robots or driverless transport systems, so that can also be a deciding factor.

What user benefits are at the forefront of the EtherCAT plug-in module concept?

Torsten Budde: Customers are able to produce their machines in a shorter time, which in turn means they can deliver them faster. This is because the concept of EtherCAT plug-in modules reduces the time required for installation and results in consistently high and uniform quality due to the elimination of wiring errors.

Getting down to the details, how does the EJ concept affect the matter of machine wiring?

Torsten Budde: Since the simple plugging in of the modules replaces complex wiring, the complete production process of the machine can be optimized. The time required for machine wiring is significantly reduced and production costs are lowered.

What does this mean for downstream process steps, such as testing and troubleshooting, or for the supply chain as a whole?

Torsten Budde: In addition to the time required for control cabinet design, the time required for troubleshooting and final testing before delivery is often underestimated. With a standard signal distribution board that is simply ‘copied’ repeatedly with the same level of quality, this effort is almost completely eliminated. If Beckhoff is supplying the signal distribution board, we can also handle the assembly of the EJ modules and the final testing. All the customer has to do is simply order the tested unit with a comprehensive order number – including housing and special clean room packaging, if required.

The shortage of skilled workers and the demand for shorter delivery times from end customers are currently the subject of intense debate in the mechanical engineering sector. To what extent do the EtherCAT plug-in modules offer advantages in this regard?

Torsten Budde: Quite simply, machine builders no longer need an electrician to plug together the machine control system because the system also prevents the EJ modules from being plugged in incorrectly with mechanical coding. With regard to delivery times, the fact that a machine can be ‘plugged together’ faster than it can be wired has a real impact, so it is ready for shipment to the customer in a shorter time without the need for time-consuming final testing processes.

To what extent can machine builders use the EJ system to relieve the strain on supply chains, which are currently under significant pressure, and bring previously outsourced value-added activities such as external control cabinet construction back in-house?

Torsten Budde: Machine builders can store complete sets of pre-tested signal distribution boards and EtherCAT plug-in modules together with tested cable harnesses in their own warehouses. When an order is received, these machine components can enter the production process directly, and the typically time-consuming processes of coordinating and ordering via an external control cabinet design company are no longer necessary.

Can the advantages of the EtherCAT plug-in modules mentioned be substantiated with concrete figures based on previous customer projects – for example, as a measure of time or cost savings?

Torsten Budde: That always depends on the application in question, but it can be illustrated very well using the following two examples: For Swiss machine tool builder GF Machining Solutions SA, the EtherCAT plug-in modules significantly reduced the error rate compared to individual wiring, and the fact that they require almost 40% less wiring effort also significantly lowered costs. Building a conventional control cabinet with DIN rails requires about 20 hours of work, but with the EtherCAT plug-in modules, it only takes 10 to 12 hours. Mühlbauer GmbH & Co. KG, a special machine builder in the chip card and passport production sector as well as in the semiconductor industry, was able to save around 100 hours of assembly time with the DS Merlin die sorting system, plus the time previously spent on error identification and troubleshooting.