The XTS linear transport system in hygienic design enables completely new, highly flexible machine concepts for the beverage industry. Together with the stainless steel Panels, I/O modules and servomotors, it provides an all-stainless steel control system for filling plants. In conjunction with our technologies for cloud-based automation, users can realise technological advances and optimised efficiency in production including lot size 1 manufacturing, product personalisation and maximised system availability.

More about this video

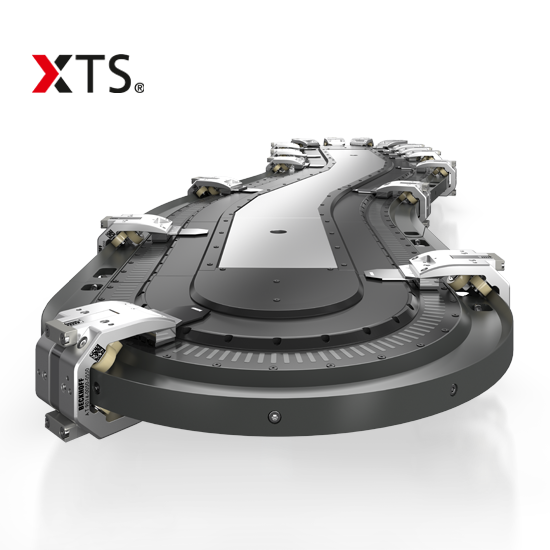

XTS | Linear product transport

As an intelligent transport system, the eXtended Transport System enables flexible motion profiles and new types of machine concept.

Packaging machines

PC-based control increases the productivity and flexibility of packaging machinery.