Food packaging requires high-quality, flexible and resource-saving solutions. In addition to ever smaller production batches and increasing production speed, traceability and complete electronic process documentation and validation are becoming increasingly important. With PC-based Control, Beckhoff offers a control solution for highly efficient, flexible and compact filling and packaging machines. PC-based Control is particularly suitable for applications in which high speed and precision are required or where complex motion connections have to be implemented. Maximum flexibility is guaranteed in situations where packaging systems are to be adapted to changing requirements without high implementation costs or if new functionalities are to be seamlessly integrated.

TwinCAT is the integrated software and engineering platform for all automation processes, including PLC, Motion Control, robotics and Condition Monitoring. All control and drive components are fully scalable in terms of performance and design. Open interfaces in hardware and software ensure continuous communication from the sensor to the cloud. Further advantages include the integrated safety solution and support of common industry standards such as FDA, EHEDG, Weihenstephan standards, OMAC and GPM.

Beckhoff technology highlights for the food industry

The control system for process automation

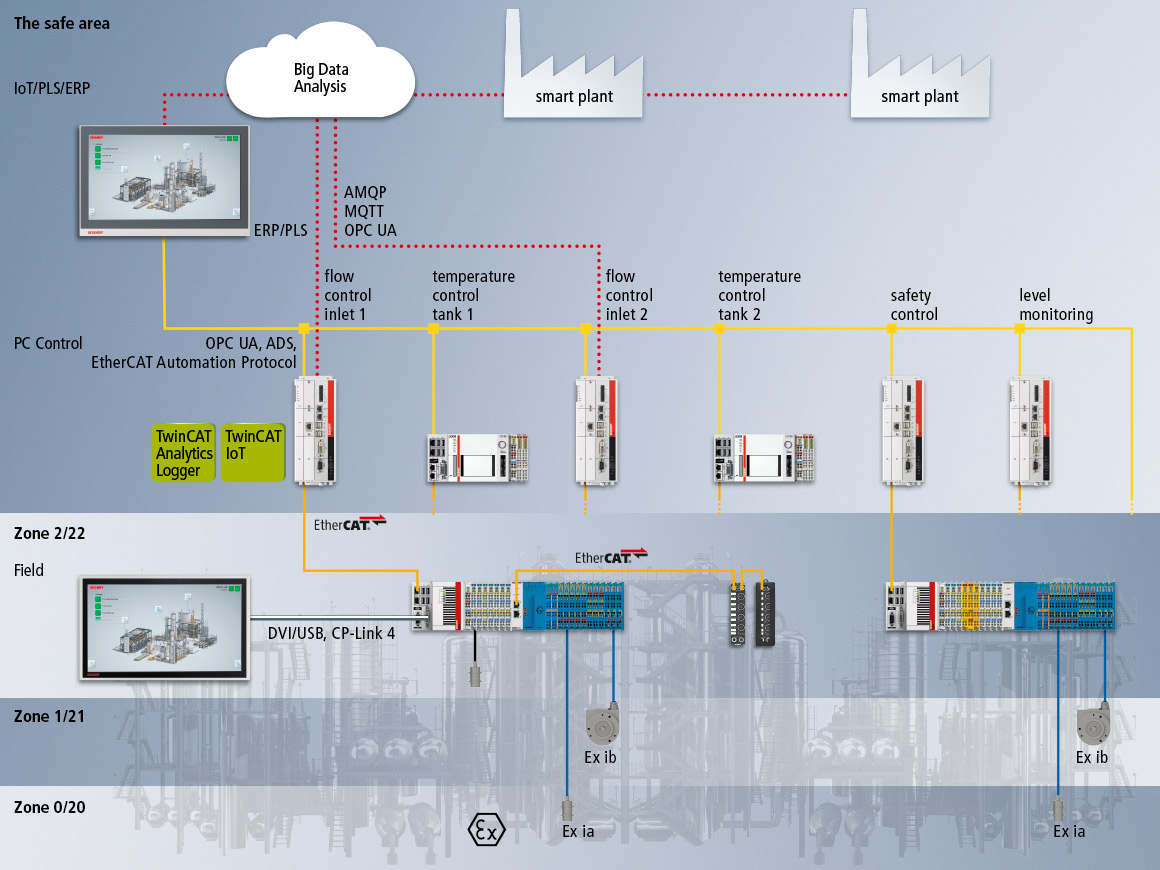

Beckhoff calls on a comprehensive range of modular components and deep-rooted, cross-sector expertise to create open automation systems using PC-based control technology. All control functions, such as PLC, visualization, cloud connection, measurement and safety technology are integrated on a consistent platform.

The system-integrated solution from Beckhoff offers an efficient alternative to traditional suppliers and is suitable for use in numerous markets, including oil and gas production, chemicals and petrochemicals, the hydrogen industry, metal processing, or the water and energy industries.

PC-based control for the process industry:

- universal hardware and software platform for the automation of all process technology applications

- extensive portfolio of components for explosion protection

- high level of interoperability for investment protection and maximum flexibility

- controller and cable redundancy for increased plant availability

- established worldwide across all industries

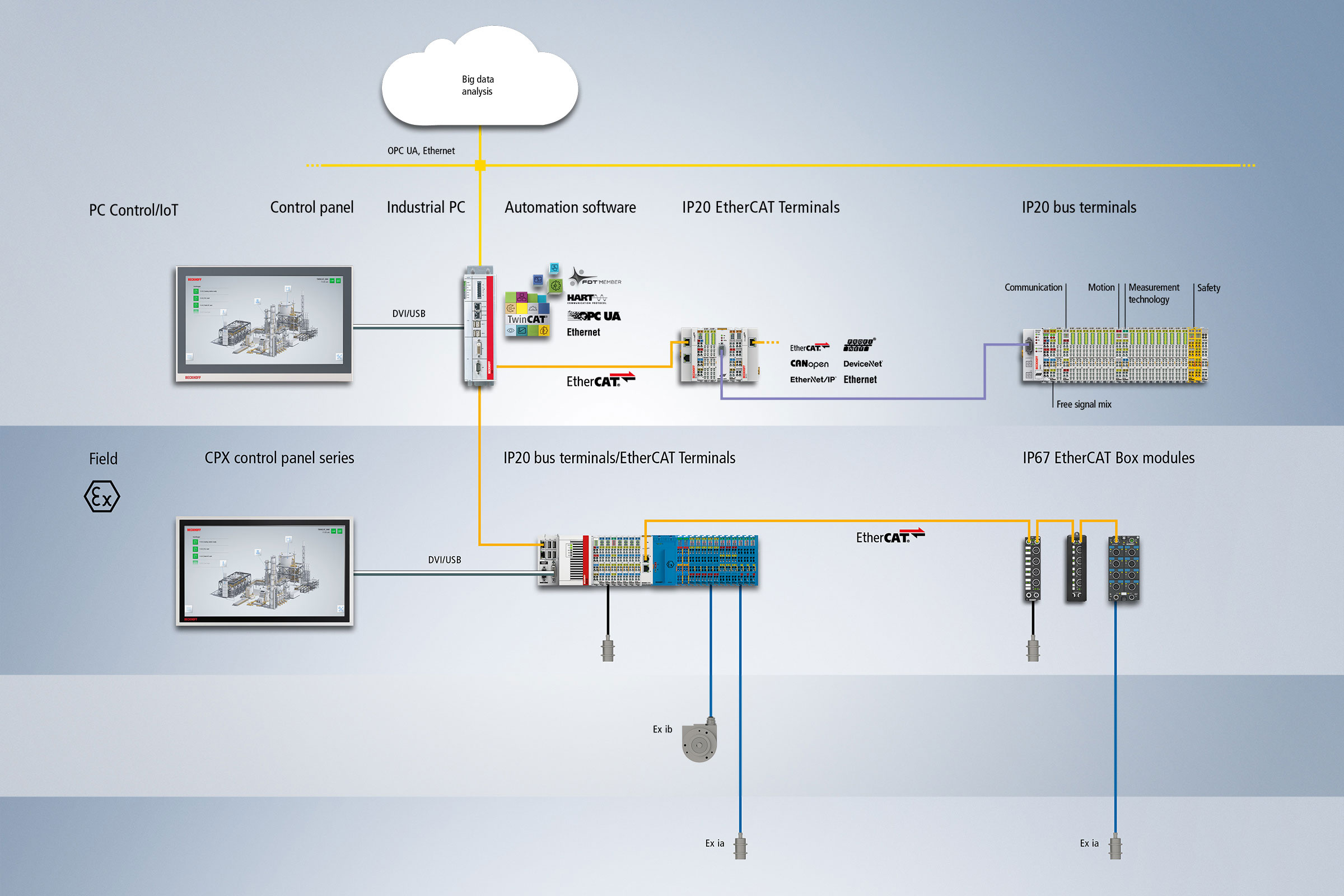

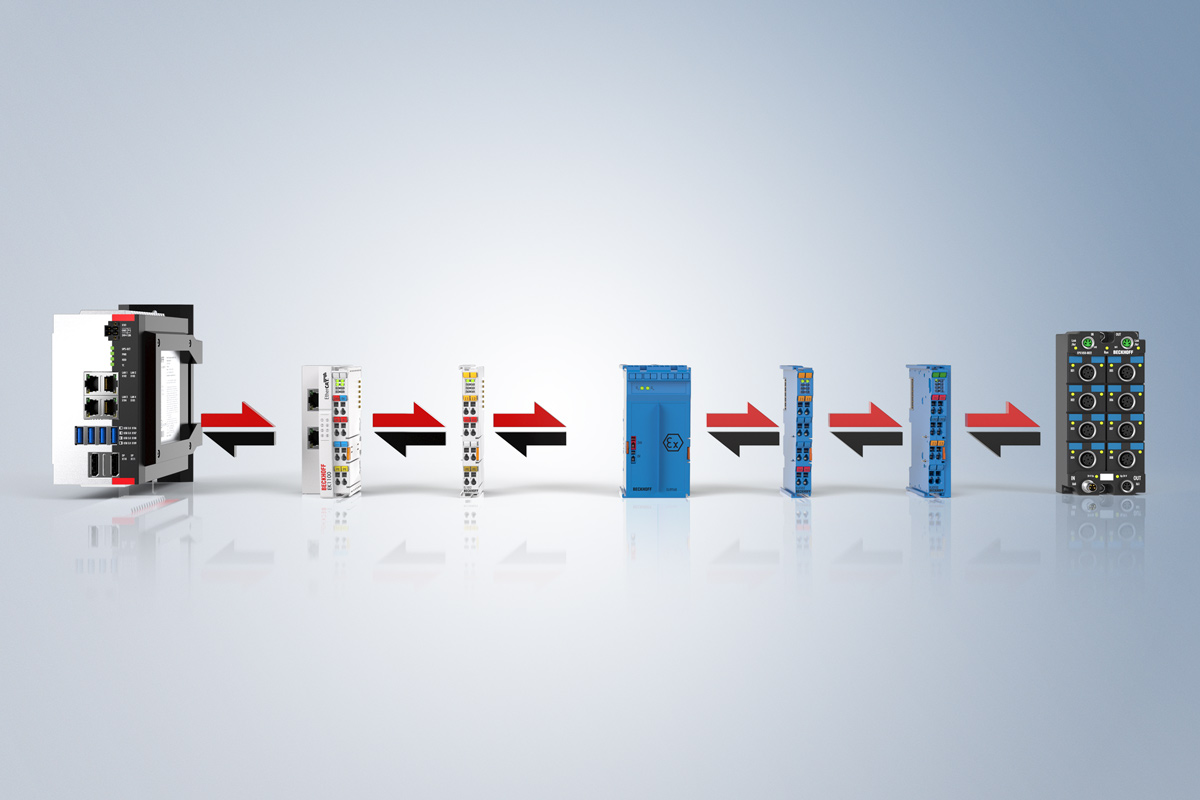

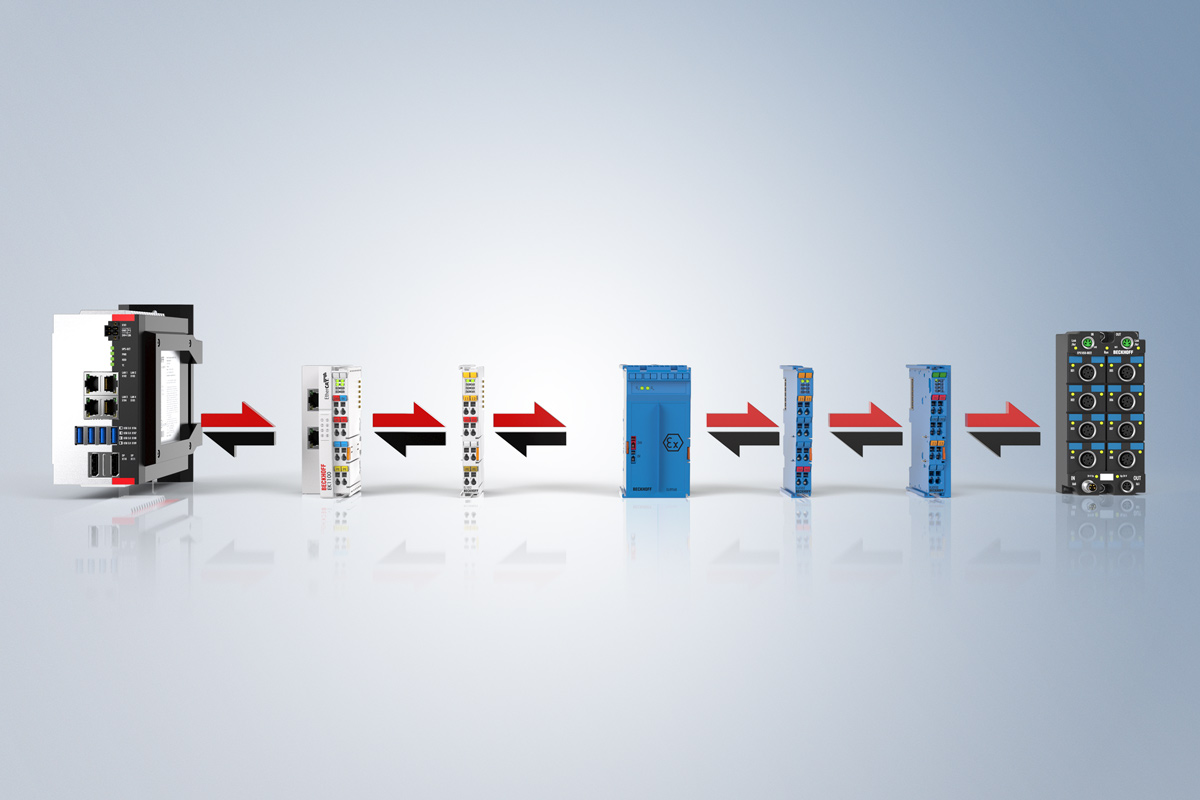

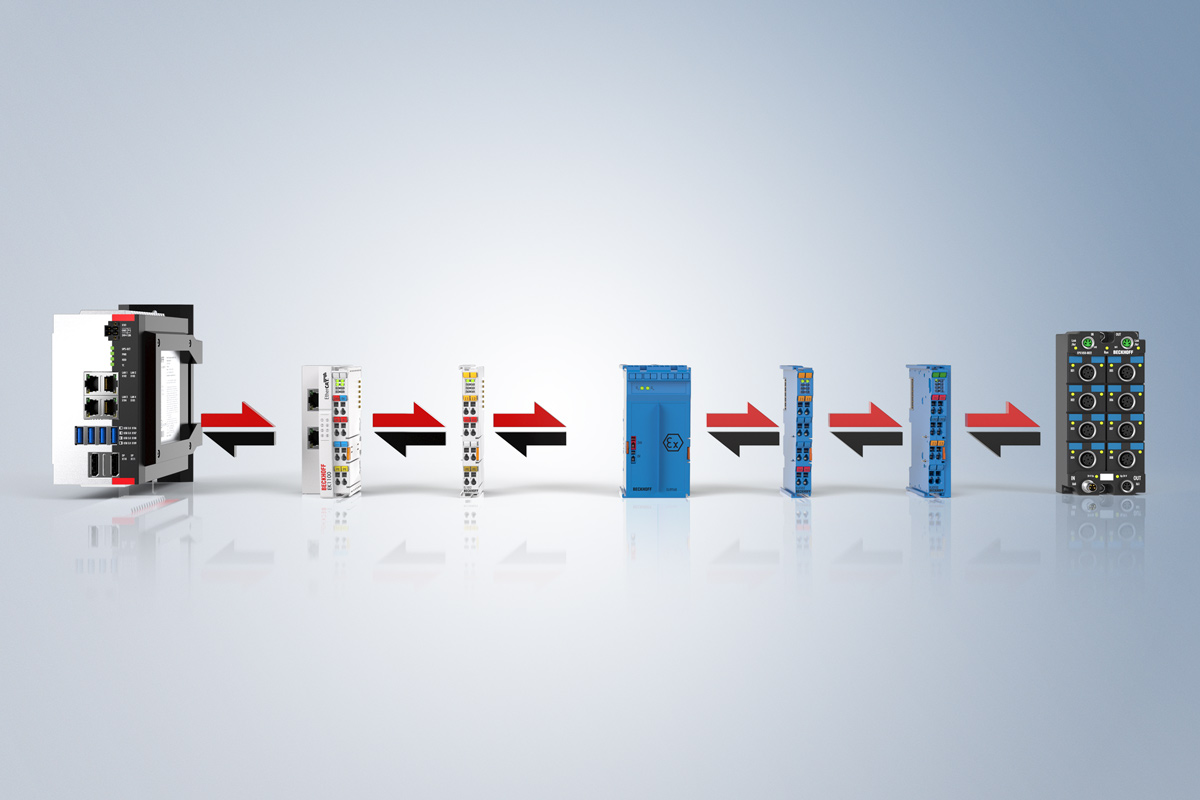

EtherCAT Terminals integrate all control functions

Beckhoff uses the principle of PC-based control technology to combine a wide range of I/O components in a single system. For example, EtherCAT Terminals used for integrating functional safety can be freely combined with EtherCAT measurement terminals for precision and high-speed measuring, as well as with I/O modules featuring an integrated safety barrier for connecting intrinsically safe field devices from the hazardous area. These elements can then be integrated into a comprehensive control system, offering plant operators an efficient complete solution for all application-related requirements.

Flexible plant design with PC-based control:

- integration of all I/O components into a single system

- combination of safety, measurement technology, and explosion protection

- openness towards third-party systems

- high interoperability to simplify retrofits

- system openness for investment protection

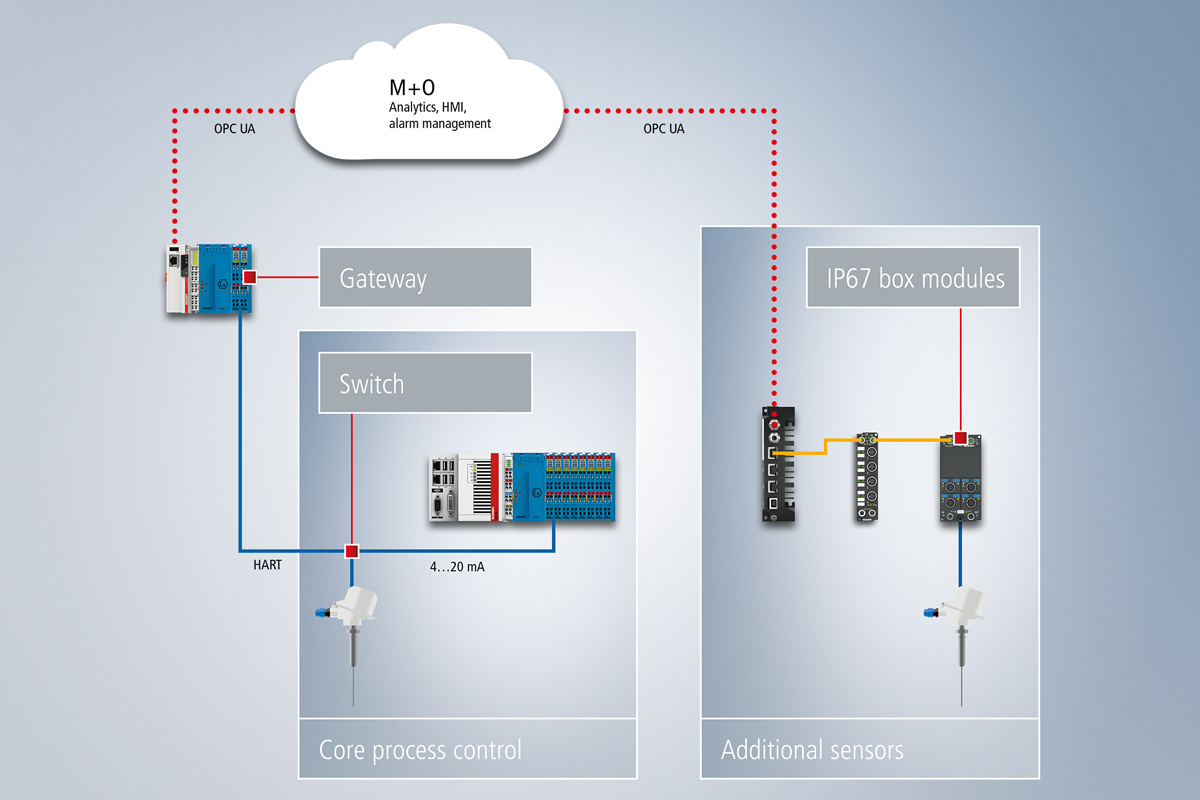

Simplifies the commissioning of field devices: TwinCAT

The full integration of the HART functionality into both the I/O system and the TwinCAT engineering environment ensures simple project planning and commissioning. The HART integration allows users to integrate HART field devices directly into the controller. In addition, TwinCAT reduces engineering effort: The TwinCAT FDT container enables the integration of field device DTMs directly into TwinCAT Engineering and thus offers programming and field device configuration in one environment.

Beckhoff ComDTM enables seamless integration of TwinCAT controllers into existing process control systems. DTMs from the field devices connected to the HART-capable EtherCAT Terminals can be integrated in any desired FDT containers with the help of the ComDTM. This allows field devices to be configured and parameterized remotely in the containers without the need for access to the PLC. Thanks to the comprehensive integration of the HART protocol in TwinCAT, the functions from the Engineering interface can be used.

Integrated controller redundancy increases plant availability

With plant availability playing such a crucial role in the process industry, measures to increase this include using redundant architectures to safeguard against failures of individual control components. For redundant controller operation, TwinCAT Controller Redundancy is available.

The system-integrated software solution allows two standard industrial PCs to be operated as redundant controllers that both run the same PLC program in just a few steps. An additional, high-performance network connection between the two controllers provides the necessary data synchronization, and the fact that standard Ethernet is used means no dedicated hardware components are required. With virtually no effort at all, this ensures that only one of the two industrial PCs addresses the fieldbus components at any given time and that the control programs are executed on both computers with the same database. If one controller fails, the second controller seamlessly takes over, preventing plant downtime and data loss.

Flexible automation components for NOA concepts

NAMUR Open Architecture (NOA) is designed to make data easily and securely available for plant and equipment monitoring and possible optimization without affecting existing automation systems. This is where our modular range of automation components allows us to offer a whole host of flexible solutions.

Many plants feature intelligent field devices that provide further data in addition to the measured value; however, this is often not taken into account, as is the case with HART field devices operated as 4…20 mA sensors, for example. In this case, the device data can be acquired by retrofitting a controller with HART-compatible I/O modules and made available via OPC UA. Depending on the application, the installation of additional sensors for condition monitoring is also useful. Here, the EtherCAT Box modules with an IP67 protection rating can be used. They can be installed directly in the field and thus require no space in the control cabinet.

Ideal for the process industry: The open EtherCAT fieldbus

As a universal and open high-speed fieldbus, EtherCAT is suitable for all areas of application, from PLC and drive technology to sensors, measurement and safety technology, and explosion protection. This means users only need a single communication technology for their entire plant. They can also rely on our in-depth expertise and benefit from the safety and optimal performance of the comprehensive EtherCAT architecture. Besides, the EtherCAT-based control is open with regard to integrating third-party EtherCAT devices and other fieldbus systems.

With its extended distance technology, EtherCAT also simplifies data acquisition across expansive areas by allowing communication over distances of up to 300 m. This can be realized via two EK1101-0010 Couplers which accept standard EtherCAT Terminal blocks. For greater distances, fiber optic solutions with a transmission length of up to 100 km are available. EtherCAT cable redundancy is used to set up a fault-tolerant ring topology to ensure that the network or network segments of a plant are always accessible. Moreover, the EtherCAT diagnostic concept enables comprehensive, complete, and fast error identification. This minimizes downtime, reduces maintenance requirements, and increases the availability of the plant.

Beckhoff product highlights for the food industry

Universal stainless steel: the complete control solution in hygienic design

For packaging applications in the food, beverage and pharmaceutical industries, Beckhoff offers a complete control solution in stainless steel with hygienic design that meets the strictest sanitation and cleanroom requirements.

Control Panels and Panel PC series in high-quality stainless steel housings are suitable for IP65 conditions.

EtherCAT Box I/O modules are also available in stainless steel housings. They meet the requirements of the IP69K protection rating and are designed to be installed directly on the machine.

The AM8800 stainless steel servomotors feature protection rating IP67 (IP69K optional) for use in extremely harsh or corrosive environments. The portfolio of stainless-steel products is complemented by the XTS Hygienic: With water-proof execution in IP69K protection rating, hygienic design without sharp corners and angles, and resistance against aggressive cleaning agents it is ideal for use in primary packaging applications and the food industry.

XTS enables completely new machine concepts for packaging

The linear transport system XTS (eXtended Transport System) unites the benefits of rotary and linear systems. XTS is a mechatronic system containing all functions necessary for operation: a modular, fully integrated linear motor with power electronics and position measurement in a single device, a mover as a moved part and a mechanical guide rail. The most diverse applications can be realized with these few coordinated components. The desired geometries, lengths and radii are formed by the number and choice of the components. XTS enables individual product transport with a continuous flow of material. XTS offers both the benefits of flexible routing and of direct drives, such as high dynamics, positioning accuracy, low oscillation, lack of wear, and low power consumption. Since both straight sections and curves are used for the material transport, there are no empty trips, making for a faster overall process. And the TwinCAT automation software makes the engineering process easy with its integrated standard features such as automatic accumulation, collision prevention and shock prevention.

The ELX series: Intrinsically safe according to IECEx, ATEX and NEC/CEC

Beckhoff’s ELX terminals combine highly compact remote I/O modules with safety barriers for the direct connection of intrinsically safe field devices from zone 0/20 and 1/21. This results in extremely narrow EtherCAT Terminals for the direct connection of intrinsically safe sensors and actuators. With their high resolution and accuracy, ELX terminals guarantee the standard of measurement quality that customers have come to expect from Beckhoff over the years. Another advantage stems from the compact design of the terminals, with up to eight intrinsically safe inputs available in the 12 mm housing. The absence of intermediate external barriers not only makes for a significant reduction in the space needed in the control cabinet, but also offers real cost advantages. With certification according to ATEX, IECEx, and NEC/CEC, as well as other country-specific standards and directives, ELX terminals can be used in virtually all markets worldwide.

The ELX terminals optimize virtually all process indudstry applications:

- highly compact design

- safety barrier and signal terminal combined

- direct connection of intrinsically safe field devices

- wide variety of signals

- comprehensive range of certificates

- considerable cost advantages

EPX modules combine IP67 protection rating with intrinsic safety

The EtherCAT Box modules in the EPX series combine intrinsic safety with an IP67 protection rating and are suitable for the implementation of modular and control cabinet-free system concepts in hazardous areas. The robust EPX modules can be mounted directly on the machine or plant and enable the acquisition of intrinsically safe signals up to zone 0/20. In this way, they offer reliable data acquisition in hazardous areas where control cabinets cannot – and should not – be installed. What’s more, their extremely compact modular design offers significant space savings, which in turn serves to cut down on costs. Additional advantages include simple commissioning, the avoidance of installation errors due to incorrect contact assignments, and the reduced cable lengths facilitated by on-site signal acquisition.

Explosion-proof panels: The elegant CPX series with aluminium enclosures

With the CPX Panel series models, the proven multi-touch technology of Beckhoff Control Panels and Panel PCs is available in even more robust versions, complying with the requirements for use in hazardous areas classified zone 2/22. The high level of functionality and excellent build quality ensure the reliability of CPX panels even under harsh environmental conditions. The capacitive touch technology provides the typical ease of operation found on all Beckhoff multi-touch panels. The aesthetically pleasing appearance of the Beckhoff panels, and the look and feel of the aluminium housing are maintained, making them visual highlights in explosion-proof environments. The comprehensive CPX Panel range includes a large selection of display formats, sizes, installation options and features. Depending on the area of application, both the panels for control cabinet installation and stand-alone panels for flexible installation nearly anywhere in a room are available. Moreover, the fanless Panel PCs can be used for highly reliable system control.

Multi-touch panels for the process industry:

- capacitive touch technology optimizes operation

- high-end design

- robust and reliable

- flexible installation options

- distances of up to 100 m between the explosion-proof Panel and Industrial PC with CP-Link 4: transmission of video signal, USB 2.0 and power supply in one standard Cat. 6A cable

Controllers and remote I/Os allow flexible topologies

Powerful Industrial PCs form the basis for a central control station for the management and monitoring of the processes of the entire plant. Sensors and actuators are connected via remote I/Os, which transmit the data from the field to the control station via a fieldbus coupler.

Conversely, with the CX series of embedded PCs, which are certified according to ATEX, IECEx and NEC/CEC for use in zone 2/22, the control of a plant part can run locally in the control cabinet, which opens up potential for more efficient process automation, especially with regard to modularization. In addition, the various functions of TwinCAT automation software are usable directly in the field.

In both cases, the appropriate selection of the controller or coupler can ensure communication to the higher-level system via the required protocol.

Module automation with TwinCAT MTP

The modularity of process systems is standardized by the Module Type Package concept (MTP). MTP describes individual modules based on various aspects, including their interfaces and the executable services. The information about the module is stored in an MTP file, which is then imported into a higher-level control, which enables efficient commissioning and linking of modules from different manufacturers. The integration of the MTP concept into TwinCAT simplifies the guideline-compliant automation of a plant module through automatically generated source code and libraries for PLC programming. As a result, a prefabricated project structure is provided in which the user merely programs the process-specific functions of the service states. Subsequently, an MTP containing the module description can be exported directly from the TwinCAT project.

Benefits of TwinCAT MTP:

- generates and exports MTP automatically

- highly customizable for easy adaptation to existing processes

- standard-compliant IEC 61131 function block library

- simple MTP/P&ID import

- seamless integration with TwinCAT Engineering

- can be combined with TwinCAT XCAD Interface

ELX terminals: intrinsically safe signal transmission and functional safety

Beckhoff meets the requirements for process control technology regarding functional safety with the full integration of safety technology into the automation system. Compact and with a modular structure, the TwinSAFE safety solution fits seamlessly into the control platform. PC-based control thus offers a single platform that meets the requirements of both functional safety and explosion protection. The ELX terminals extended with TwinSAFE SC thus enable the direct connection of intrinsically safe field devices up to zone 0/20 for safety-related functions.

Functional safety and intrinsic safety in one system:

- highly compact solution with up to four channels across only 12 mm

- direct connection of intrinsically safe field devices up to zone 0/20

- functional safety

- considerable cost advantages

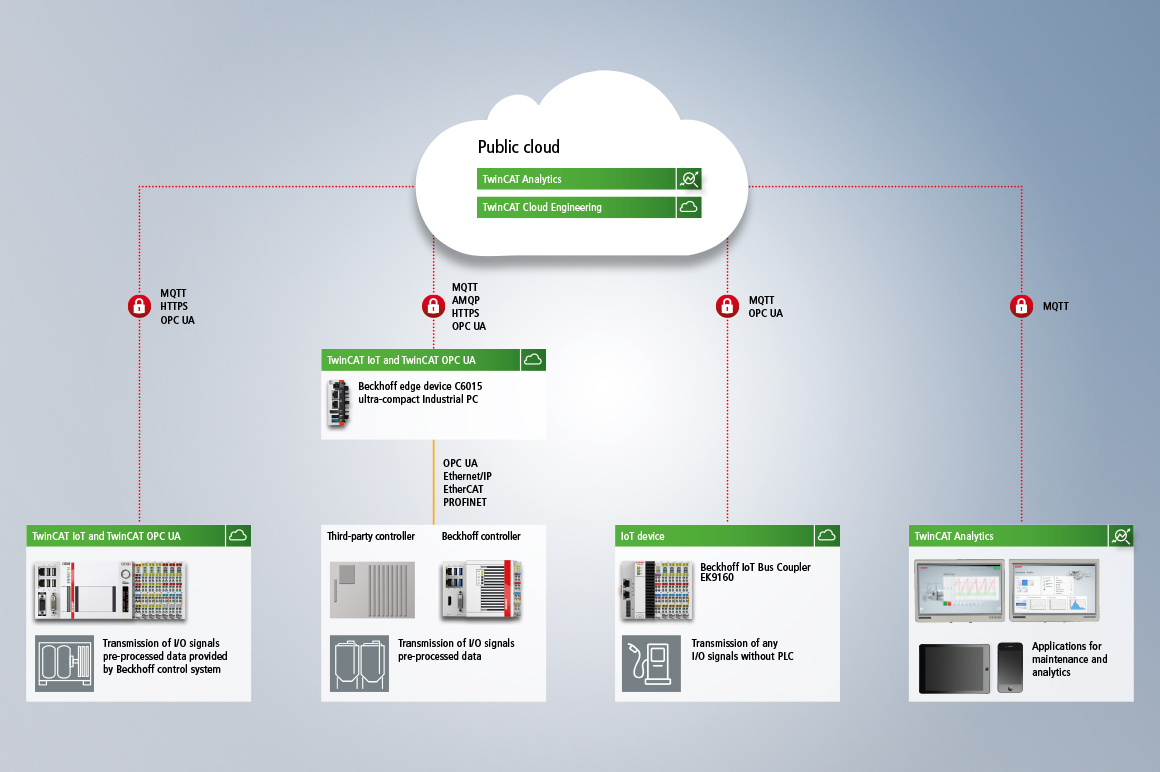

TwinCAT: The control platform for process industry

In the TwinCAT automation software Beckhoff provides a central platform for controlling process machines and systems. In addition to classic process control in the PLC program, algorithms written in C++ or MATLAB®/Simulink® can also be executed in real time. Moreover, TwinCAT includes the HMI, the secure cloud connection via TwinCAT IoT and the use of cloud-based analytical functions via TwinCAT Analytics. The field of application of PC-based control is expanded with the extensive integration of specific process technology protocols and interfaces. TwinCAT supports all common protocols such as NAMUR, HART and FDT/DTM, covering all application areas.

TwinCAT highlights for the process industry:

- a single tool for engineering and runtime

- control-integrated Industrie 4.0 and IoT applications

- comprehensive data evaluation with analytics functions

- standardized communication via OPC UA

- simplified field device configuration via FDT/DTM

- execution of MATLAB®/Simulink® models

From sensor to cloud – universal solutions for the process industry

In the process industries, forward-looking automation solutions are required to enable cross-system connectivity. The traditional divide between discrete and process automation is no longer an obstacle. PC-based control technology offers all the essential prerequisites for a convergence of technologies in both application areas. It also provides the capability to integrate decentralized systems and enable centralized process control and evaluation at the same time. With its openness, PC-based control is also the ideal basis for realizing networked production in accordance with Industrie 4.0 and IoT concepts: from horizontal integration – even across company boundaries – to vertical integration with production systems to end-to-end engineering throughout the entire product lifecycle.

We developed the TwinCAT IoT software library for communication between the machine control system and cloud-based services. The library supports the standardized protocols OPC UA, AMQP and MQTT for communication with popular cloud systems such as Microsoft Azure™, Amazon Web Services, as well as private cloud systems in the local enterprise network.