PC-based control facilitates data integration in food manufacturing

Yummy Bakery's pancakes are "hot" and end up on the shelves of virtually every major retail chain in Belgium. The secret behind this success? Using the authentic ingredients and preparation method on a baking plate. A recipe that perfectly combines with digitalization as CTRL Engineering successfully demonstrated. Besides 7 to 8% raw material savings, the automation of dough dosing with control technology from Beckhoff also helped provide data for ongoing process optimization.

Annie Alderweireldt's life in Bruges didn't always revolve around pancakes. But when her pregnancy forced her to stop working in 1984, they did give her an outlet. "She started experimenting in the kitchen until she had the recipe for the perfect pancake, using the neighbors as guinea pigs," says her daughter Sara Geldhof, who runs the business with her brother Tom today. "She then went to the local bakers and butchers in Dudzele near Bruges to market her pancakes." A snowball effect, because before she knew it, they were on the shelves of convenience stores and the big supermarket chains also discovered her. "Mom's arm pouring the dough onto the baking plate over and over again in the same fluid motion with a ladle ... that was actually our first machine. But at some point that was no longer feasible. So we built a carousel that worked semi-automatically at least," Sara Geldhof recalls.

Authentic preparation method, authentic taste

In 1995, they had the opportunity to purchase a piece of land in an industrial park in Bruges. A first industrial pancake machine went up and running there. But authenticity was still as hard-won as ever. Sara Geldhof explains: "We achieved the typical taste by opting to prepare via griddle. Compared to using infrared technology, the pancake is then seared immediately, so the dough inside stays soft and creamy. In addition, only natural ingredients enter the recipe, no preservatives or colorings, just pure nature." A philosophy that Yummy Bakery also applies to their new products. For example, they already have organic pancakes in the product range and are working behind the scenes on the first vegan pancakes. "And will continue do so until the taste is completely right," Sara Geldhof says. What started with the industrial production of traditional pancakes from Bruges, now also serves current trends, for example with motif pancakes for Halloween.

Complete automation enables growth

The acquisition of a second production hall followed eight years ago. Maybe a happy twist of fate, because only a year and a half ago, Yummy Bakery could use the space to increase its production capacity from 10,000 to 22,500 pancakes per hour. And still the growth curve is going up: last year, sales increased 25%. "We couldn't ignore automation and digitalization anymore if we wanted to keep up with our growth. We are all about fresh products, so everything we produce goes straight out the door. In the past, you could manage that with a good team that had all the necessary know-how in their heads. Today, though, you have to secure that knowledge using technology. The goal is to create a complete digital flow that improves our process stability and minimizes repetitive work for our employees." To achieve this, Yummy Bakery partnered with CTRL Engineering who have a background in automotive. "In automotive production lines, the goal is zero errors. Because profit margins are limited, the entire process is completely purged of inaccuracies. We want to introduce these principles to other sectors as well. Together we look for ways how our customers' processes can be improved to produce more with the same machines and people. What we offer is efficiency as a service," Managing Director Pieter Meseure summarizes the mission of the company.

Fast Return on Investment

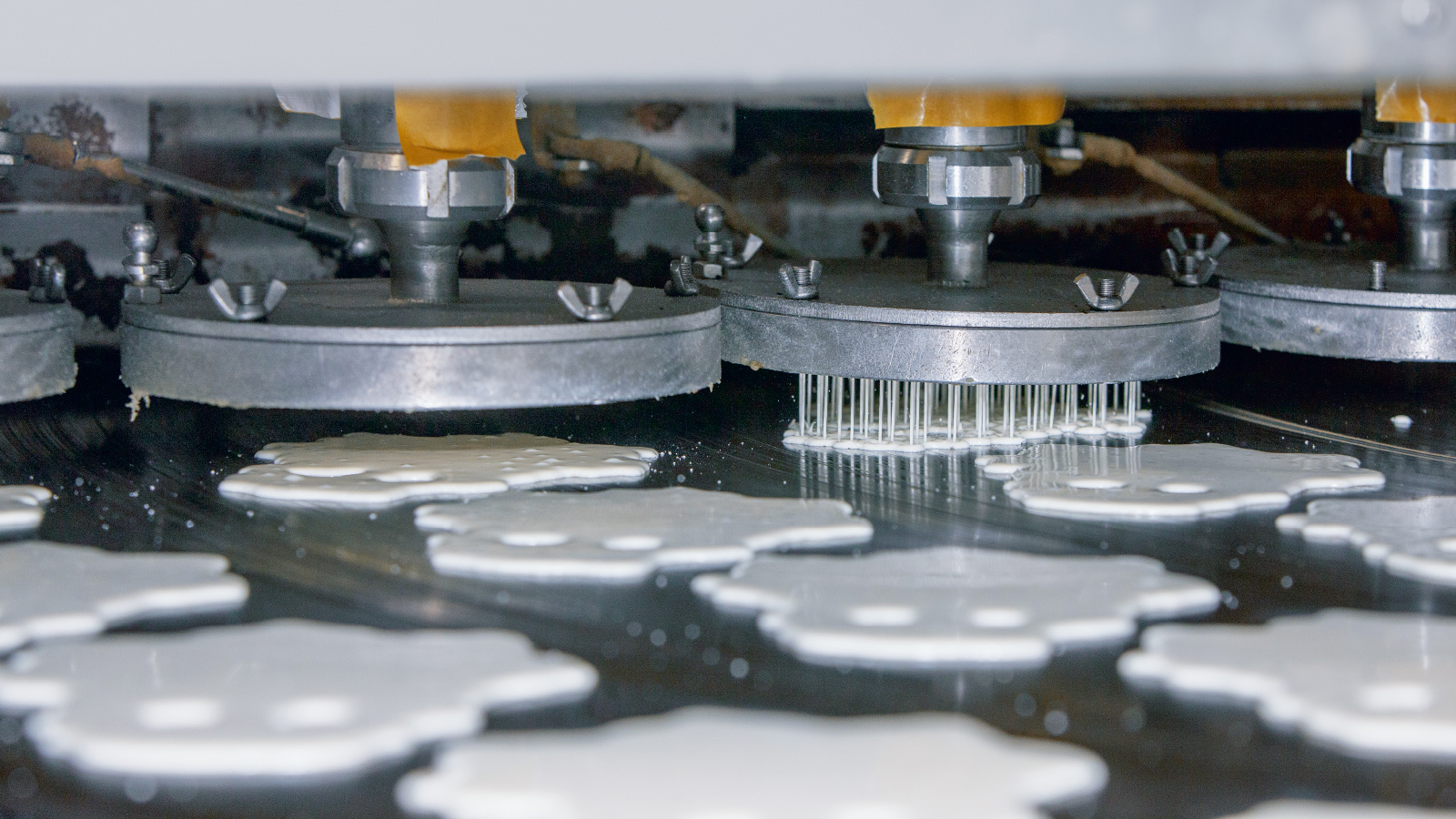

Although Yummy Bakery and CTRL Engineering both wanted to set the bar high, they decided to start small. "We started looking for the low-hanging fruit. Something that would give us immediate profit, so that we had more resources to take the next steps in digitalization," says Pieter Meseure. The lack of stability in the weight of the pancakes was the first item on the agenda. Mathieu Dutré, Director of Innovation and Business Development at CTRL Engineering, explained: "We were wondering, if we can save 10% overweight, what impact would that have on the bottom line? A calculation pointed to an ROI of less than a year. That was a no-brainer!" Until then, dosing had been done pneumatically, that is, depending on the recipe, operators would have to adjust the compressed air flow rate manually. As a result, a pack of pancakes with a nominal weight of 500 g could weigh between 500 g and 560 g. CTRL Engineering used virtual engineering to see how they could best address the problem and what hardware would suit the specifications they found.

Servomotor as a virtual sensor

The first step was introducing pressure control on the four nozzles of the machine. Pieter Meseure says: "Now it is calculated as a function of a motor's torque. Because in order to achieve the proposed weight savings, the settings need to be continuously improved. To this end, we created a closed control loop using the servomotor as a virtual sensor. In addition, we process input from a scale that is used to monitor the average and trend in the pancakes’ weight to detect deviations. The data from a checkweigher located at the end of the packaging line is also integrated into the model. After all, the cooling tower the pancakes have to pass first also has an impact on the weight."

Seamless integration of data

All measured data are converged on a cloud platform, an in-house development by CTRL Engineering. In this way, the deviation in the pancakes’ weight has already been reduced to 0.4 g, which corresponds to a 7 to 8% gain through raw materials that are not wasted. "And we are also already seeing how we can get to a 0.1 g deviation over time," Mathieu Dutré adds. It all sounds surprisingly simple, and it is for the operators, who need only click on the right recipe. In the background, however, complex algorithms and models are running to calculate a digital twin of the physical machine. "For this, integration of data is key, which is why the backbone of our solution consists of Beckhoff control technology. Their PC-based control platform allows you to add functionalities through software, without having to change the hardware," Mathieu Dutré says. Pieter Meseure also cites the openness of the system as an asset: "In TwinCAT, we can seamlessly link all kinds of systems and data, allowing us to respond quickly to changes." On the shop floor a Beckhoff CX5240 Industrial PC serves as controller. Furthermore, the CP3916 Control Panel catches the eye. "In stainless steel execution it is perfect for application in the food industry," says Mathieu Dutré. "Not only does the Beckhoff technology do everything it is supposed to do on the shop floor, there is a knowledgeable team behind it that is always available."

One digital flow to mirror the production process

In terms of digitalization,this is just the tip of the iceberg for Yummy Bakery. The next step? "Automating quality inspection at the end of the packaging line by adding vision capabilities. We are just waiting for the OCR functionality to be introduced. Behind the scenes, Beckhoff is already training a machine learning model to recognize even more fonts. The potential profits from that should in turn serve to eventually install a second production line in the new building, adding another 50% of capacity. Then we can transfer all production facilities from the first building to here and repeat the process until we achieve one perfect, digital flow," Pieter Meseure concludes with an outlook into the future.